MI Series Crawler Mobile Impact Crusher

MI series crawler mobile impact crusher, also called crawler mobile impact crushing station, each module is compact and efficient, with hydraulic assistance in many places, and a return material screening system is installed. There is also an iron removal air screening device, which can be used for primary and secondary crushing. The return material belt can be adjusted to output the finished material laterally.

MJ Series Crawler Mobile Jaw Crusher

MJ Series Crawler Mobile Jaw Crusher is equipped with European C Series crushing machine, super large folding silo, independent pre-screening system, and iron removal spray device. It is mainly used for primary crushing of materials, with large feed size and wide discharge range, suitable for all kinds of rocks. Convenient transfer and high crushing efficiency.

XFD-I Single Cell Flotation Machine

XFD-I Single Cell Flotation Machine is a laboratory-scale flotation device primarily used in the mineral processing industry. It is designed for testing flotation behavior of various ores to help determine the feasibility of flotation separation processes on a small scale before scaling up to industrial equipment.

Centrifugal Gold Concentrator

Centrifugal gold concentrator is an advanced gravity separation machine designed for high-efficiency recovery of fine free gold and other precious or heavy metals from alluvial, hard rock, and tailing materials.

Disc Granulator

Disc granulator, also known as disc granulator, is a widely used equipment in industries such as agriculture, chemical industry and mining to granulate powdered materials into uniform solid particles.

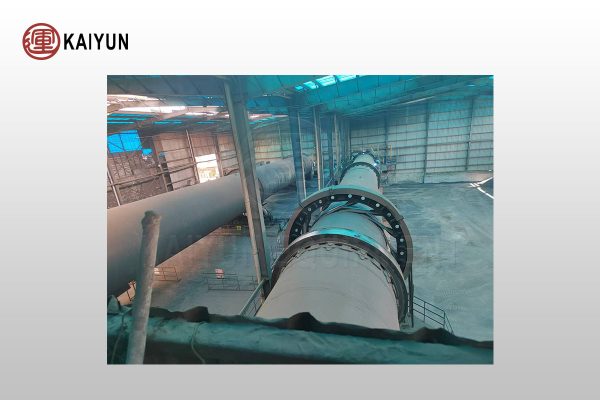

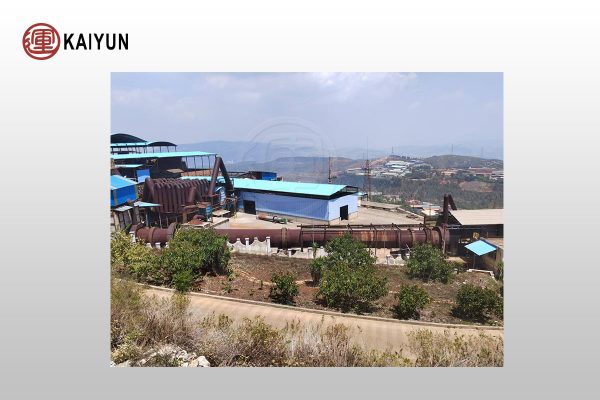

Kaolin Rotary Kiln

Kaolin rotary kiln is a kind of equipment specially used for calcining kaolin. Kaolin is a non-metallic mineral widely used in papermaking, ceramics, coatings, rubber and other industries. By calcining kaolin in a rotary kiln, its chemical stability, whiteness and adsorption can be improved, and its physical and chemical properties can be improved, making its performance in industrial applications more excellent.

Solid and Hazardous Waste Disposal Rotary Kiln

Solid and hazardous waste disposal rotary kiln is a key device for the harmless, reduced and resource-based treatment of various hazardous wastes such as industrial waste, medical waste, and chemical waste.

Active Lime Rotary Kiln

Active lime rotary kiln ensures that the produced lime has high activity and excellent physical and chemical properties through precise temperature control and efficient calcination process.

Lithium Carbonate Rotary Kiln

Lithium carbonate is an important chemical raw material, widely used in many fields such as batteries, glass, ceramics and pharmaceuticals, especially in the lithium battery industry. The lithium carbonate rotary kiln extracts lithium elements from lithium ore through a high-temperature calcination process to produce high-purity lithium carbonate.

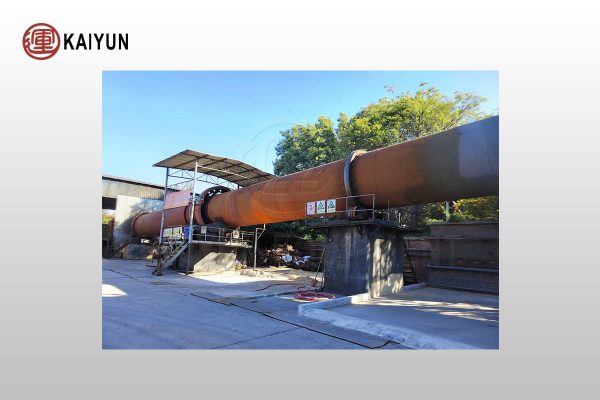

Cement Rotary Kiln

The cement rotary kiln is one of the key equipment in cement production. It is mainly used for high-temperature calcination of cement clinker and is the core link of the "burning" stage in the cement manufacturing process. The rotary kiln converts raw materials into clinker through high-temperature calcination and is an indispensable equipment in the modern cement industry. The high efficiency and continuous working ability of the cement rotary kiln make it the basis for large-scale cement production.

Ceramic Rotary Kiln

Ceramic rotary kiln is mainly used to roast ceramsite raw materials, and the raw materials are processed into ceramsite products with certain strength, density and durability through high temperature. It is widely used in building materials, metallurgy, chemical industry, environmental protection and other industries.

Zinc Oxide Rotary Kiln

Zinc oxide, as an important chemical raw material, is widely used in rubber, ceramics, medicine, paint, batteries and other fields, and zinc oxide rotary kiln is an indispensable equipment in its production process.

- « Previous Page

- 1

- …

- 5

- 6

- 7

- 8

- 9

- …

- 14

- Next Page »