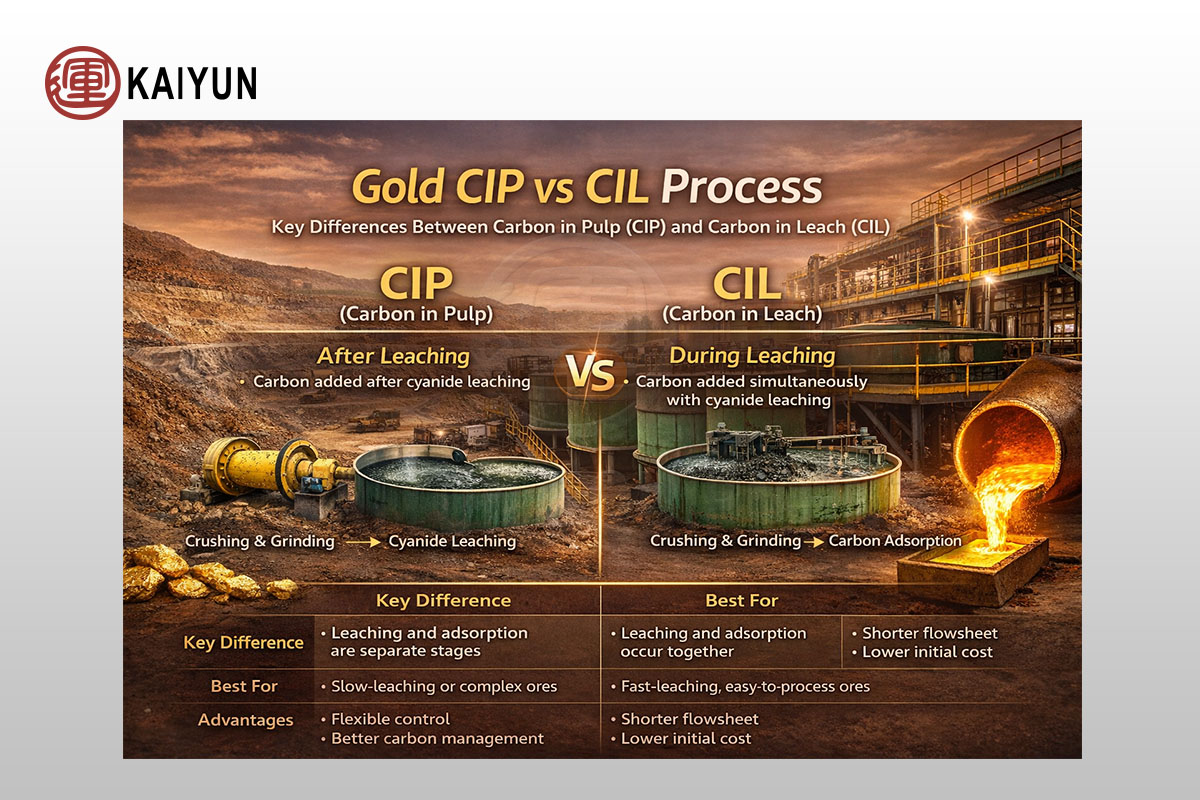

Gold CIP vs CIL Process Detailed Comparison(II)

Gold CIP (Carbon in Pulp) and Gold CIL (Carbon in Leach) are two of the most widely used cyanide gold extraction processes. Both technologies are mature, reliable, and capable of achieving high gold recovery — when properly matched with the ore characteristics.

Gold CIP vs CIL Process Detailed Comparison(I)

Gold CIP (Carbon in Pulp) and Gold CIL (Carbon in Leach) are two of the most widely used cyanide gold extraction processes. Both technologies are mature, reliable, and capable of achieving high gold recovery — when properly matched with the ore characteristics.

Gold CIP vs CIL Process | Difference, Selection & Plant Solution

Compare Gold CIP and CIL processes. Learn key differences, applications, recovery performance, and how to choose the right gold processing solution for your ore.

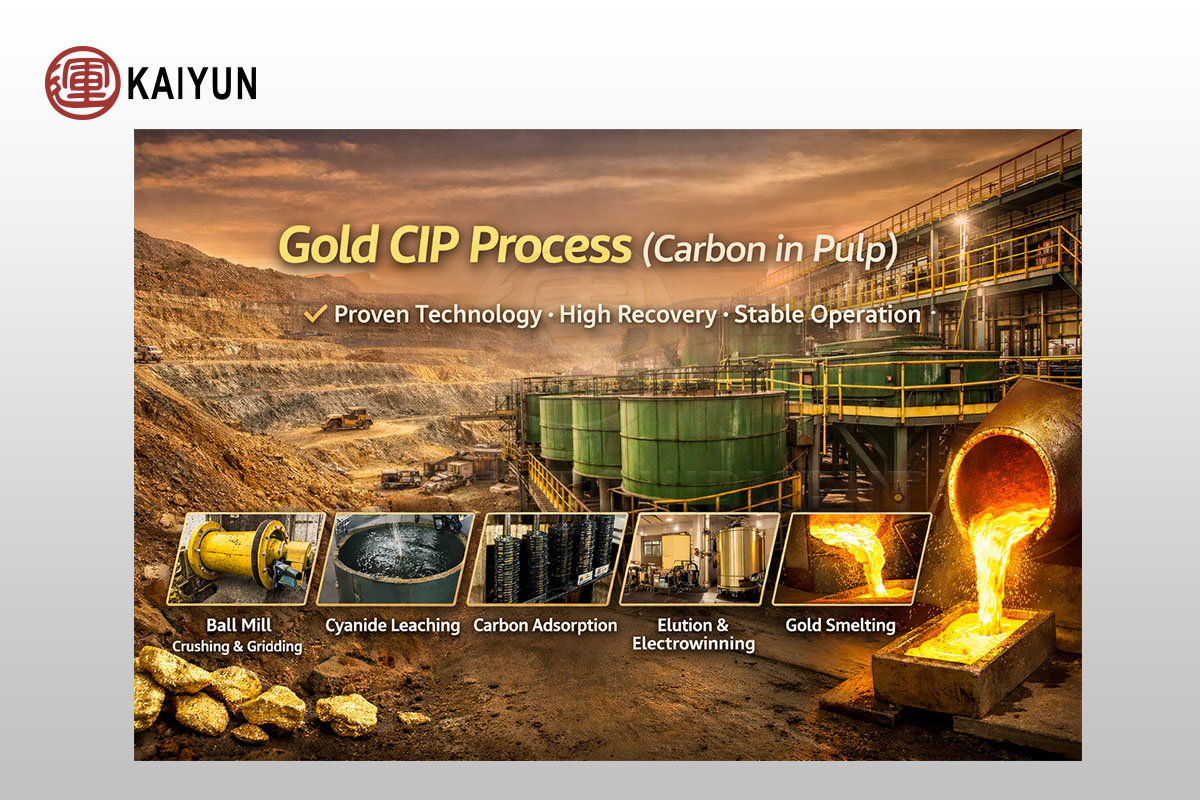

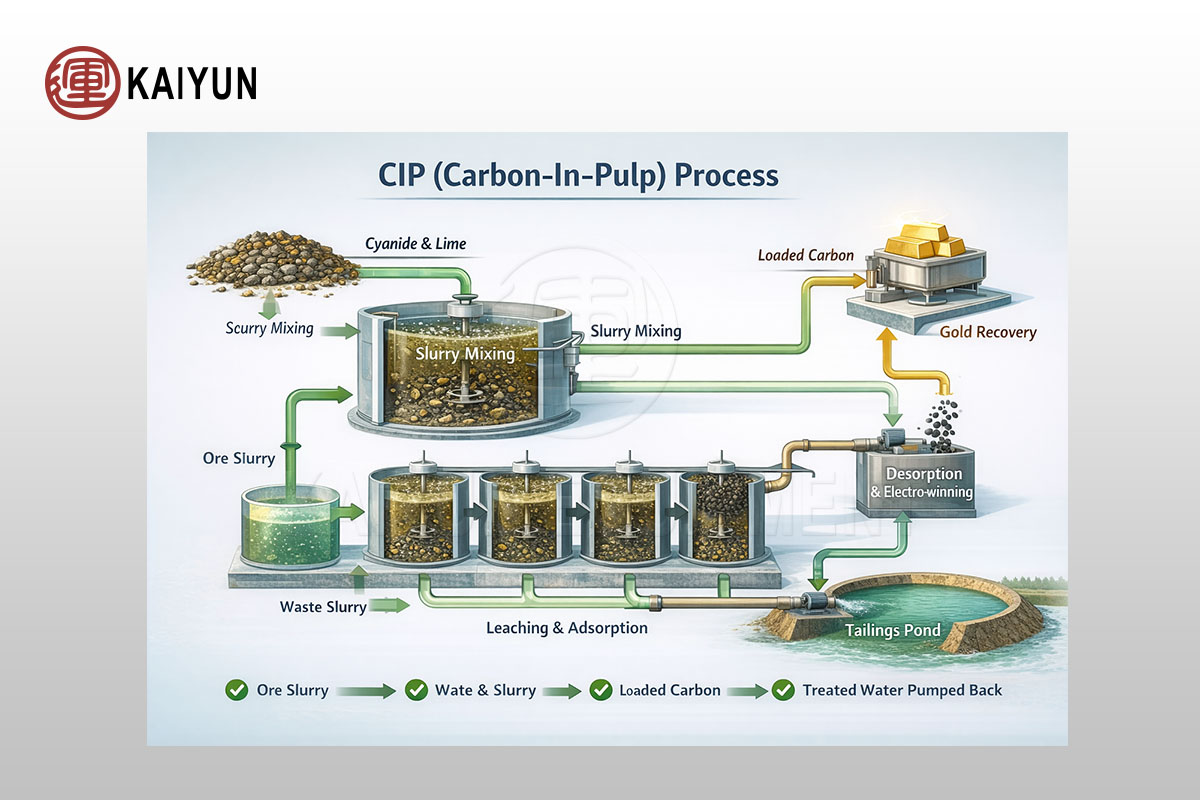

Gold CIP Process | Carbon in Pulp Plant FAQs & Solutions

Gold CIP (Carbon in Pulp) processing plant for gold recovery. Learn process flow, applications, recovery efficiency, and operating cost. Request a solution now.

Wet Magnetic Separator | FAQs, Applications & Technical Solutions

Wet magnetic separators for iron ore, magnetite, ilmenite, and tailings recovery. Learn capacity, applications, advantages, and customization options. Request technical support now.

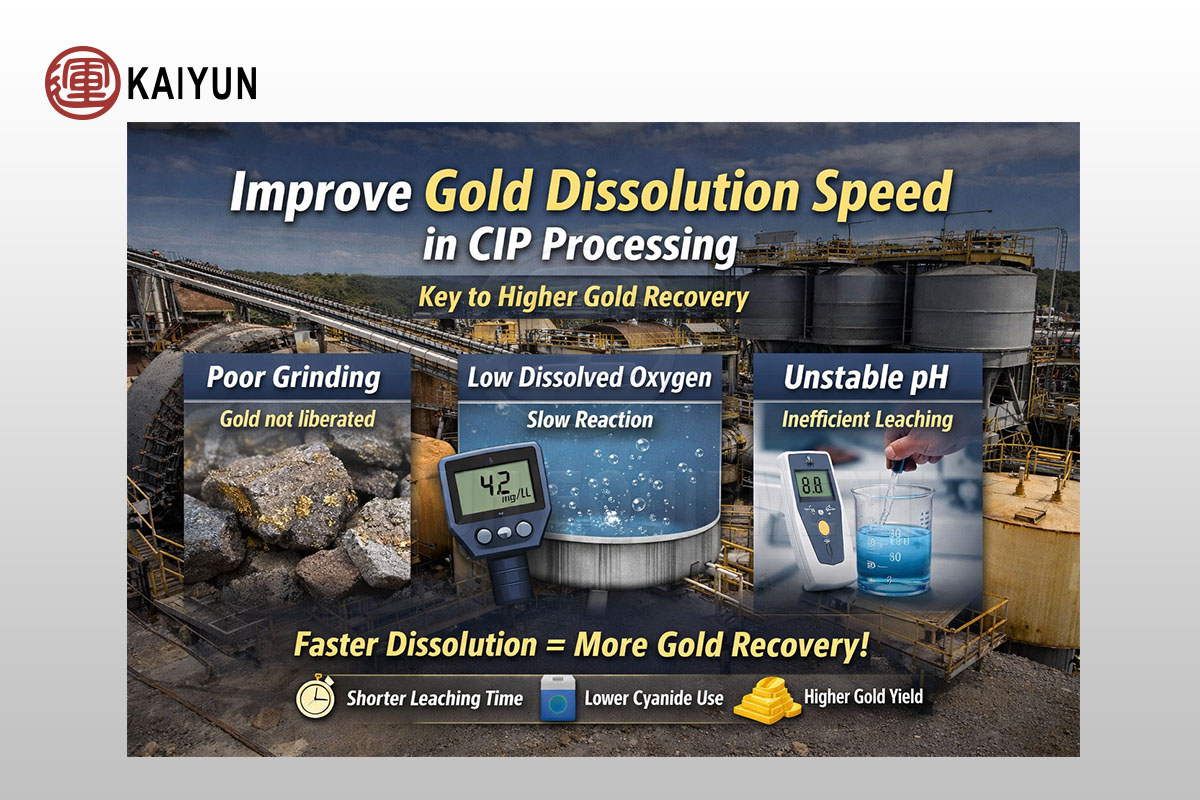

Improve Gold Dissolution Speed in CIP Processing | Higher Recovery & Lower Reagent Cost

Learn why improving gold dissolution speed is critical in the CIP process. Optimize leaching time, reduce cyanide consumption, and achieve higher gold recovery.

When and Why to Choose CIP for Maximum Gold Recovery

Discover when to choose the CIP (Carbon-in-Pulp) process for gold extraction. Learn about ore types, gold particle size, and conditions for maximum recovery efficiency.

Gold CIP Processing Plant

Gold CIP processing plant for stable and cost-effective gold recovery. Suitable for oxide gold ores. Complete turnkey solution from testing to commissioning.

Common Misunderstandings About Magnetic Separator Applications(II)

Learn the most common mistakes in magnetic separator applications, including wrong ore selection, improper magnetic intensity, and poor process design. Improve recovery and reduce operating costs.

- « Previous Page

- 1

- 2

- 3

- 4

- …

- 9

- Next Page »