Common Misunderstandings About Magnetic Separator Applications(I)

Learn the most common mistakes in magnetic separator applications, including wrong ore selection, improper magnetic intensity, and poor process design. Improve recovery and reduce operating costs.

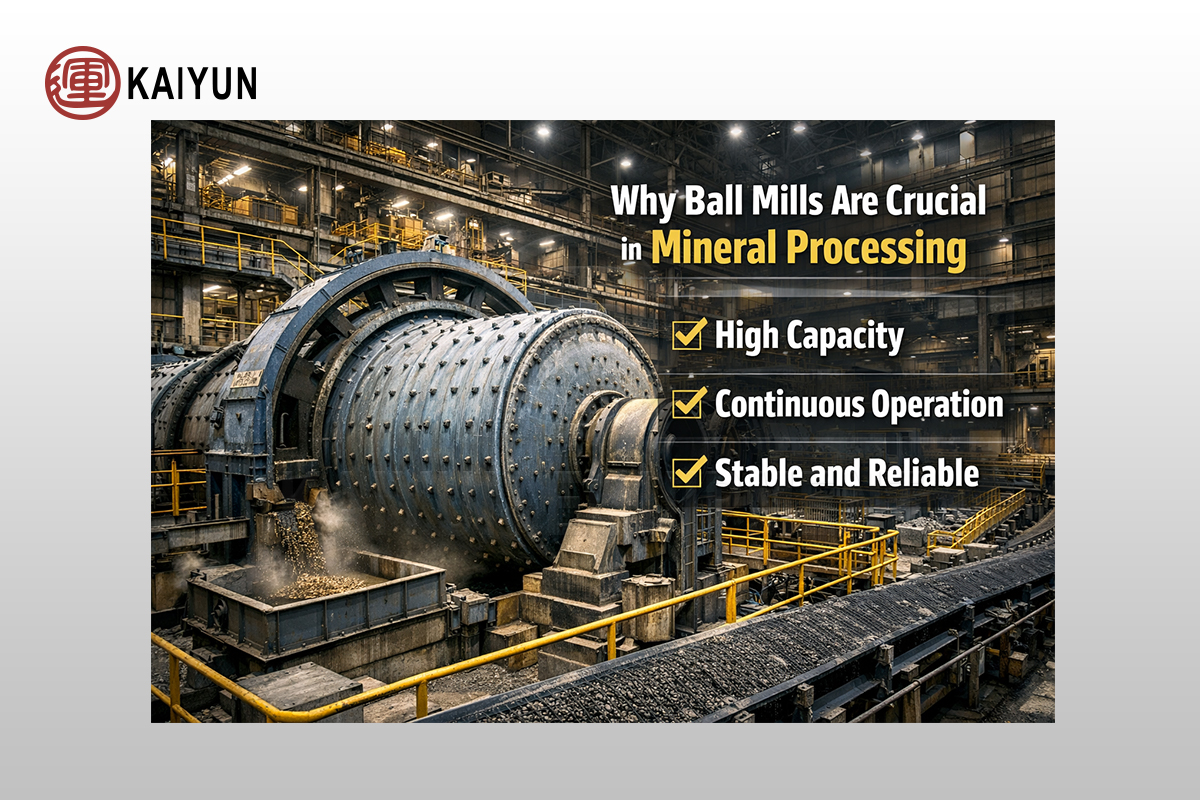

The Importance of Ball Mills in Gold Mining Processing

Ball mills play a critical role in gold mining processing by improving grinding efficiency and gold recovery. Learn how to choose the right ball mill for your gold project.

5 Key Technical Parameters You Must Know Before Buying a Jig Machine

Before buying a jig machine, understand feed size, capacity, stroke, water use, and maintenance. Get the right model for higher recovery.

Does a Centrifugal Concentrator Recover Coarse Gold and Fine Gold Differently?

Learn how centrifugal concentrators perform differently when recovering coarse gold vs. fine gold. Understand key factors, challenges, and the best process solutions.

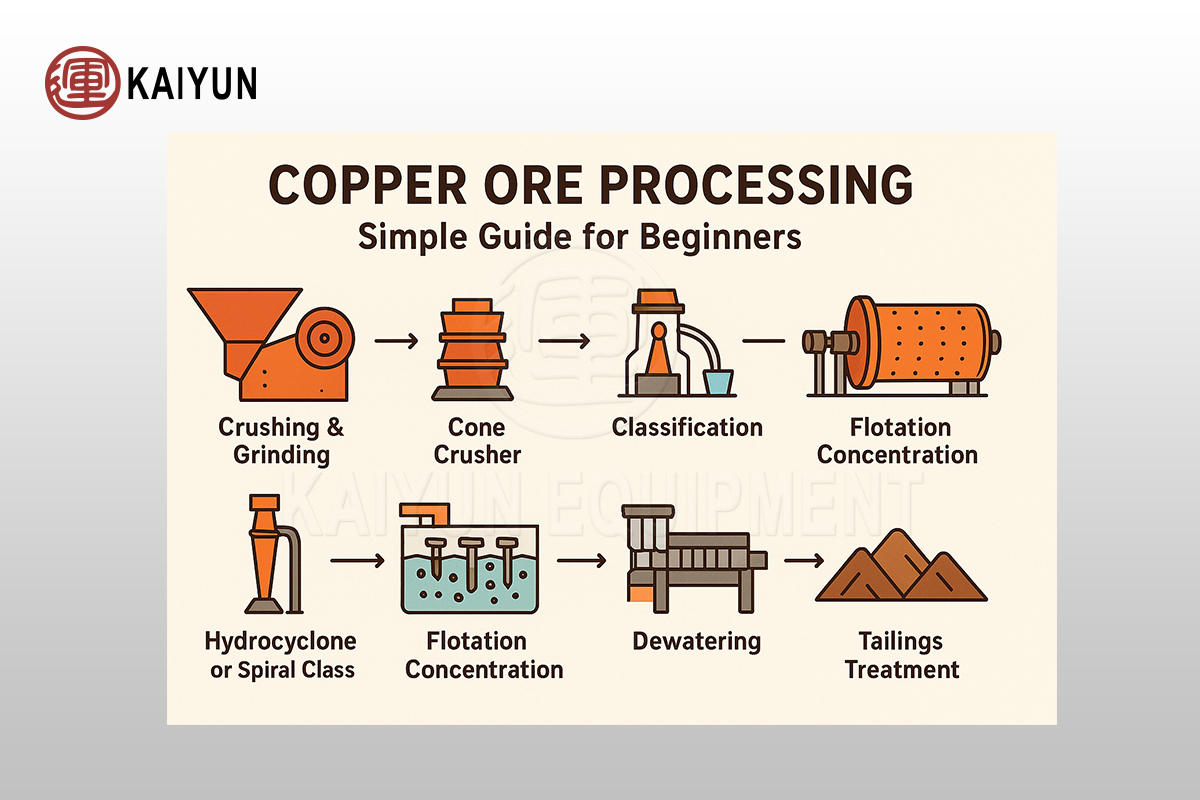

Copper Ore Processing: A Complete Beginner’s Guide to Building a Successful Copper Mining Line

Copper ore processing is not a single-machine job. From crushing to concentration, every step plays a key role in ensuring high recovery, stable output, and low operating costs. If you're new to copper mining or planning to start a processing plant, this guide will give you a clear, easy-to-understand overview of the full production process.

Gold Mining Cannot Be Done With a Single Machine: What Every Beginner Must Know

In reality, gold mining is a complete processing system, not a single-machine operation. Only a full set of coordinated equipment and a proper process flow can recover gold efficiently.

How to Install and Commission a Centrifugal Concentrator?

The centrifugal concentrator is a key piece of equipment for small and medium-scale gold recovery. Correct installation and commissioning directly determine the recovery rate, service life, and overall plant efficiency.

Flotation Equipment – High Recovery Solutions for Low-Grade Ore Processing

High-efficiency flotation machine designed for low-grade ore and tailings recovery. Improve recovery rate by 3–12%, reduce reagent consumption, and achieve stable concentrate grade. Ideal for copper, gold, fluorite, lead-zinc, and complex ores.

Small-Scale Gold Mining Solutions: How to Achieve Higher Recovery at Lower Cost?

With global gold prices continuing to rise, more small and medium-sized mining investors are looking for low-investment, fast-commissioning, and high-recovery solutions to enter the gold mining industry.

- « Previous Page

- 1

- 2

- 3

- 4

- 5

- …

- 9

- Next Page »