In modern gold ore processing, no single method is perfect for all types of ores. That is why professional mineral plants often combine different beneficiation techniques to maximize recovery and improve economic efficiency. Two of the most important methods are gravity separation using centrifugal concentrators and flotation technology. But can they actually work together in the same process? The answer is yes – and they complement each other very well.

How Centrifugal Concentrators Work

Centrifugal concentrators, such as the STLB or Knelson type, use high gravity force to recover fine gold particles from slurry. They are especially effective in capturing:

Free gold and other heavy minerals

Fine particles down to 20–30 microns

Material with relatively simple mineral liberation

Their advantages include low energy consumption, water-saving operation, and easy management, making them an ideal pre-enrichment device.

How Flotation Works

Flotation, on the other hand, is a physico-chemical process that separates minerals based on surface properties. By adding reagents and introducing air bubbles, fine sulfide minerals and microscopic gold locked in sulfides can attach to bubbles and float, while gangue sinks. Flotation is particularly suitable for:

Complex ores containing sulfides

Extremely fine-grained gold

Ores that cannot be recovered by gravity methods alone

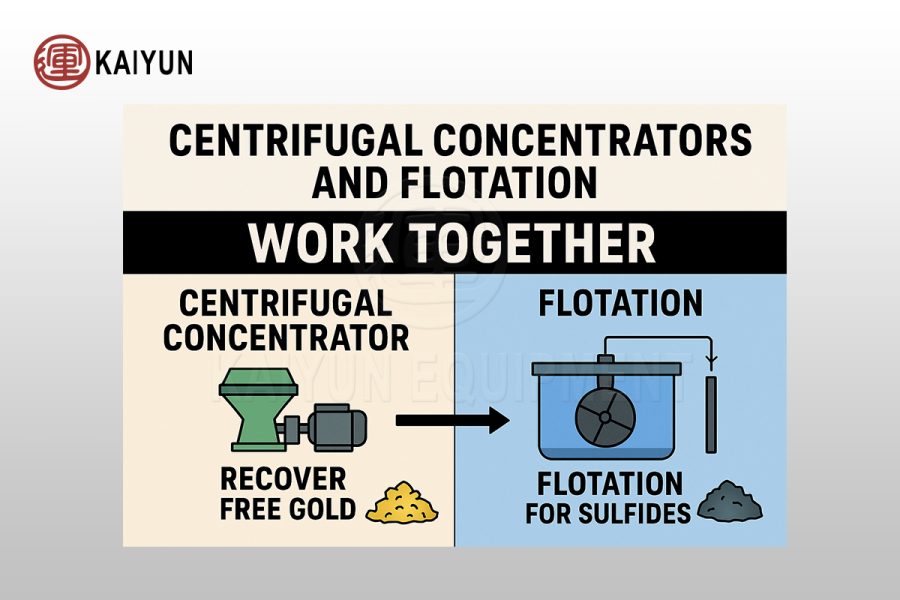

Why Combine Centrifugal Concentration and Flotation?

In practice, many gold plants use both methods in different stages of processing. Typical flowsheet examples include:

Pre-concentration with a centrifugal concentrator → recover free gold first, reduce ore loss, and decrease the load of the flotation circuit.

Flotation after gravity recovery → capture fine sulfides and gold particles that escaped the concentrator.

Combined gravity + flotation tailings treatment → ensure maximum recovery and higher overall yield.

This “gravity + flotation” combination not only improves the total gold recovery rate but also reduces reagent consumption and processing costs.

Conclusion

Centrifugal concentrators and flotation are not alternatives but partners in mineral processing. For ores with both free gold and sulfide gold, combining the two is often the most efficient solution. Choosing the right configuration depends on ore characteristics, capacity requirements, and investment budget.

If you are looking for a customized solution for your gold ore, our engineering team can design a complete flowchart integrating centrifugal concentrators, flotation machines, and auxiliary equipment to achieve the best recovery performance.