Why Poor Separation Results Are Often Caused by Wrong Usage, Not the Machine

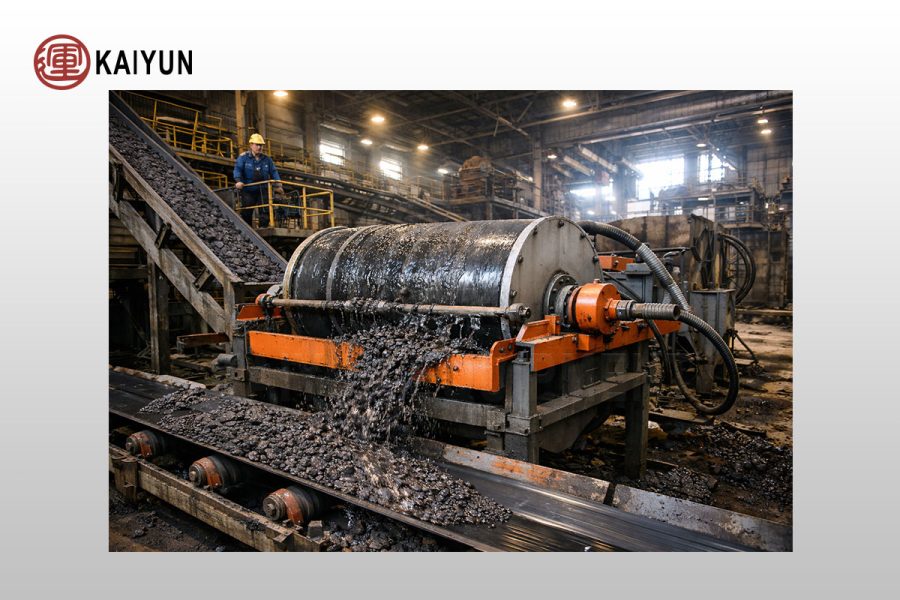

Magnetic separators are widely used in mineral processing plants.

However, in many projects, unsatisfactory separation results are not caused by equipment quality, but by incorrect application and improper selection.

Below are the most common misunderstandings we see in real mining projects.

Misunderstanding 1: All Ores Can Be Processed by Magnetic Separators

Wrong assumption

Any type of ore can be separated using a magnetic separator.

Correct understanding

Magnetic separators are effective only for minerals with magnetic properties, such as:

Magnetite

Ilmenite

Certain manganese ores

Iron impurities in quartz sand and feldspar

Not suitable for magnetic separation alone:

Gold ores (free gold, oxide gold, sulfide gold)

Copper, lead, and zinc ores

👉 Magnetic separation is selective, not universal.

Misunderstanding 2: Higher Magnetic Intensity Always Means Better Results

Wrong assumption

The stronger the magnetic field, the better the recovery.

Reality

Excessive magnetic intensity may lead to:

Non-magnetic gangue being captured

Lower concentrate grade

Poor separation selectivity

Correct approach

High-intensity magnetic separators → weakly magnetic minerals (hematite, limonite)

Low / medium-intensity magnetic separators → strongly magnetic minerals (magnetite)

👉 Magnetic field strength must match the mineral characteristics.

Misunderstanding 3: One Magnetic Separator Can Complete the Entire Process

Wrong assumption

A single magnetic separator is enough to produce final concentrate.

Actual mineral processing flow

A complete processing line usually includes:

Crushing (jaw crusher, cone crusher)

Grinding (ball mill)

Classification (spiral classifier or hydrocyclone)

Magnetic separation / gravity separation / flotation

Magnetic separators are commonly used for:

Pre-concentration

Roughing

Iron removal

👉 Magnetic separators are part of a system, not a standalone solution.

Why Proper Selection Matters More Than Equipment Price

In real projects, we often see that:

Losses caused by wrong process selection are much higher than the cost of the equipment itself.

We support our clients with:

Ore characteristics evaluation

Customized magnetic + gravity + flotation solutions

Equipment selection adapted to African mining conditions

📩 Need Professional Advice?

If you are unsure whether your ore is suitable for magnetic separation,

please share your ore type, particle size range, and capacity requirement.

Our engineers will help you design a stable, cost-effective, and high-recovery mineral processing solution.