Why Poor Separation Results Are Often Caused by Wrong Usage, Not the Machine

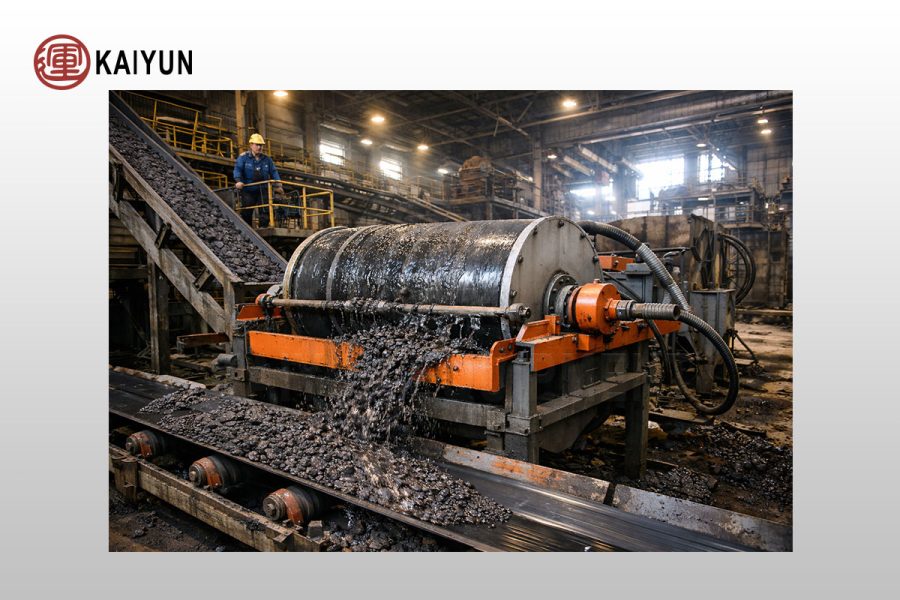

Magnetic separators are widely used in mineral processing plants.

However, in many projects, unsatisfactory separation results are not caused by equipment quality, but by incorrect application and improper selection.

Below are the most common misunderstandings we see in real mining projects.

Misunderstanding 4: Dry and Wet Magnetic Separation Are Almost the Same

Wrong assumption

Dry and wet magnetic separators can be used interchangeably.

Key differences

| Item | Dry Magnetic Separator | Wet Magnetic Separator |

| Feed material | Dry, coarse particles | Fine particles, slurry |

| Separation accuracy | Moderate | High |

| Application in Africa | Limited | Most common choice |

👉 For most African metal ore projects, wet magnetic separation offers better stability and recovery.

Misunderstanding 5: Feed Size and Pulp Density Are Not Important

Common mistakes

Feed size too coarse → minerals not fully liberated

Pulp density too high → magnetic minerals trapped in gangue

Recommended conditions

Feed size: ≤ 0.2–0.3 mm

Pulp density: adjusted according to ore characteristics

👉 Even the best equipment requires proper operating conditions.

Misunderstanding 6: Magnetic Separators Can Replace Gravity or Flotation Equipment

Wrong assumption

Using a magnetic separator eliminates the need for other separation methods.

Correct processing strategy

Gold ores → centrifugal concentrator, shaking table, flotation

Magnetite → magnetic separation as the core process

Complex ores → combined processing flows

👉 Magnetic separation solves magnetic problems only.

Why Proper Selection Matters More Than Equipment Price

In real projects, we often see that:

Losses caused by wrong process selection are much higher than the cost of the equipment itself.

We support our clients with:

Ore characteristics evaluation

Customized magnetic + gravity + flotation solutions

Equipment selection adapted to African mining conditions

📩 Need Professional Advice?

If you are unsure whether your ore is suitable for magnetic separation,

please share your ore type, particle size range, and capacity requirement.

Our engineers will help you design a stable, cost-effective, and high-recovery mineral processing solution.