In the mining and aggregate industry, materials such as granite and basalt are known for their high hardness, which makes crushing a challenge. The traditional jaw crusher + impact crusher two-stage process is common, but when dealing with ores with a compressive strength of ≥250 MPa, it often suffers from fast wear, insufficient capacity, and high maintenance costs.

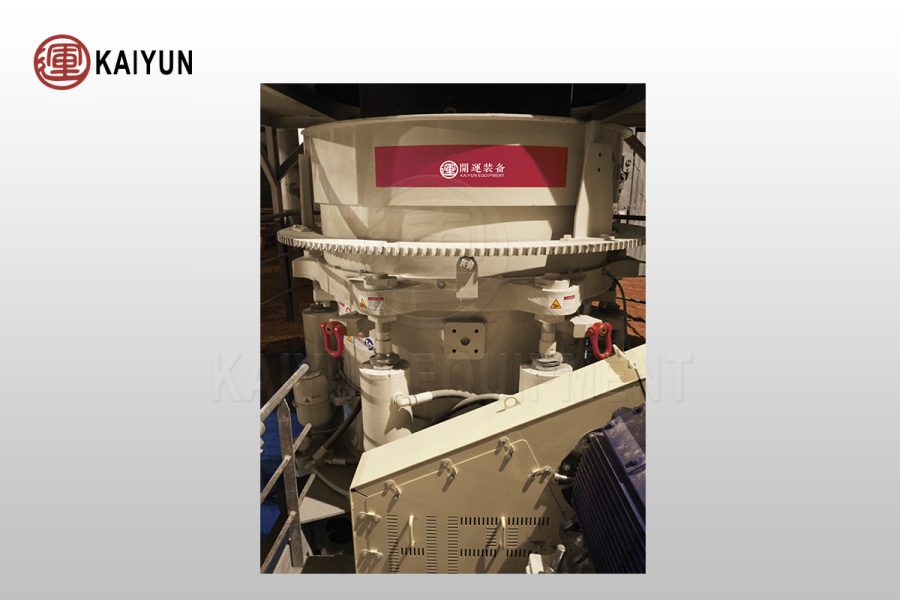

Now, more production lines are replacing this setup with a single cone crusher, which not only simplifies the process but also delivers superior fine crushing performance. The discharge size can be stably controlled at ≤30 mm, making it ideal for both sand making and high-quality aggregate production.

Why Choose a Cone Crusher?

① Designed for High Hardness Materials

Adopting the lamination crushing principle, the cone crusher easily handles granite, basalt, and other materials with a compressive strength of ≥250 MPa, producing aggregates with better shape and fewer needle-like particles.

② Single Machine for Secondary Fine Crushing

Compared to the “jaw crusher + impact crusher” combination, the cone crusher can directly complete secondary fine crushing, reducing equipment quantity, footprint, and installation time.

③ Adjustable Output to Fit Various Needs

The discharge size can be flexibly adjusted, commonly maintained at ≤30 mm for fine crushing before sand making or for producing high-quality aggregates directly.

④ Energy-Saving with Higher Capacity

Optimized structure and intelligent control systems ensure lower energy consumption and reduced production costs at the same capacity.

Application Cases: Granite Crushing Equipment & Basalt Secondary Crushing Solutions

In a large-scale aggregate plant, the client previously used a jaw crusher + impact crusher to process granite, resulting in excessive wear and insufficient output. After switching to a single cone crusher:

Capacity increased by over 30%

Improved particle shape, with reduced needle-like content

Lower maintenance costs, with longer wear part service life

Similarly, for basalt secondary crushing, the cone crusher delivers consistent discharge size, stable performance, and low downtime, ensuring continuous production.

Conclusion

Whether for granite crushing equipment or basalt secondary crushing solutions, the modern cone crusher stands out with its ability to handle high-hardness materials, versatility, and energy efficiency.

If your production line faces the challenge of crushing hard materials, or if you aim to optimize processes and reduce costs, consider making the cone crusher your primary equipment choice.