Crushing is the first and most critical step in mineral processing.

A properly designed crushing system directly affects mineral liberation, energy consumption, processing efficiency, and overall plant performance.

This page explains the role of crushing, typical crushing stages, and crusher selection principles for different ores and production capacities.

Role of Crushing in Mineral Processing

Crushing is not only size reduction — its core purpose is to prepare ore for efficient separation.

The main roles include:

Liberating valuable minerals from gangue

Crushing breaks the ore structure, allowing useful minerals to separate from waste rock, forming the basis for flotation, gravity separation, leaching, and magnetic separation.

Meeting particle size requirements of downstream processes

Grinding mills, classifiers, and separators require controlled feed size to operate efficiently.

Reducing energy consumption and improving overall efficiency

Proper crushing significantly lowers grinding energy consumption and improves plant economics.

Adapting to feeding specifications of mineral processing equipment

Stable and uniform feed size reduces equipment wear and improves operational stability.

Laying the foundation for classification and pre-concentration

Effective crushing enables early-stage classification and waste rejection.

📌 Efficient crushing is the foundation of high recovery and low operating cost.

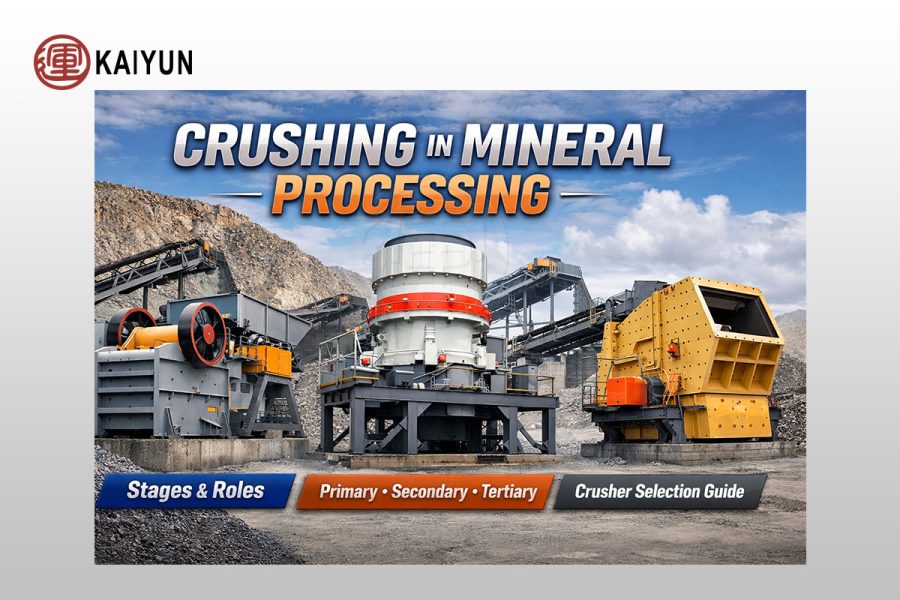

Crushing Stages in Mineral Processing

Based on crushed product size, crushing operations are generally divided into three stages.

Primary Crushing

Feed size: 1500–500 mm

Product size: 400–125 mm

Purpose: initial size reduction of run-of-mine ore

Secondary Crushing

Feed size: 400–125 mm

Product size: 100–50 mm

Purpose: prepare material for fine crushing or grinding

Tertiary Crushing

Feed size: 100–50 mm

Product size: 25–5 mm

Purpose: produce uniform fine material and improve grinding efficiency

📌 Multi-stage crushing improves capacity, reduces wear, and ensures stable downstream operation.

Crusher Selection for Ore Crushing

Selecting the right crusher depends mainly on ore hardness and plant capacity.

High-Hardness Ores (Mohs hardness > 6)

Examples: quartz ore, iron ore

Recommended solution:

Jaw Crusher + Cone Crusher

Strong wear resistance

Suitable for high-load, continuous operation

Ideal for large-scale mineral processing plants

Medium & Low-Hardness Ores (Mohs hardness < 6)

Examples: limestone, gypsum

Recommended solution:

Jaw Crusher + Impact Crusher

Balanced crushing efficiency

Better finished product shape

Lower investment and maintenance cost

Capacity Matching Principles

Large-scale production lines:

Cone crushers are preferred for high capacity and stable performance.

Small-scale processing plants:

Impact crushers or hammer crushers reduce equipment investment and O&M costs.

📌 Correct crusher selection ensures optimal performance and cost control.