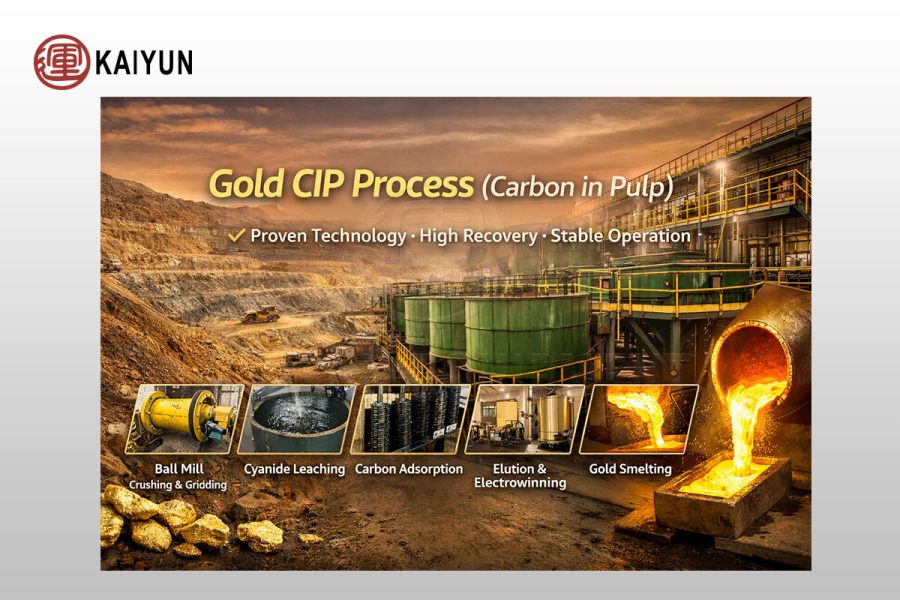

Gold CIP Process

Proven Technology · High Recovery · Stable Operation

The Gold CIP (Carbon in Pulp) process is a widely used gold extraction method for oxide gold ores and low-sulfide ores.

It integrates leaching and adsorption in a continuous circuit, offering stable performance and high recovery rates.

Screen 1|What Is the Gold CIP Process Used For?

The Gold CIP process is mainly applied to:

Oxide gold ores

Low-sulfur and easily leachable gold ores

Medium- and small-scale gold processing plants

It is especially suitable for ores with fine gold particles and good cyanide leachability.

Screen 2|Typical CIP Process Flow

A standard Gold CIP plant includes:

Crushing and grinding

Slurry preparation

Cyanide leaching

Carbon adsorption in pulp

Gold-loaded carbon elution and regeneration

The integrated design improves adsorption efficiency and process stability.

Screen 3|Recovery Rate & Performance

Key advantages of the CIP process:

High gold recovery rate

Efficient adsorption for fine gold particles

Stable and continuous operation

Lower gold loss compared with conventional methods

Recovery performance depends on ore grade, particle size, and process control.

Screen 4|Operating Cost & Plant Management

Moderate reagent consumption

Simple process control

Reliable equipment and easy maintenance

Suitable for long-term continuous operation

The CIP process helps reduce overall operating and maintenance costs.

Screen 5|Plant Design & Custom Solutions

Customized CIP plant solutions available:

Processing capacity and ore characteristics

Equipment selection and layout design

Integration with existing plants

Technical support and commissioning

Suitable for:

New gold processing plants

Plant upgrades and expansions

Gold tailings reprocessing projects

📩 Get Your Gold CIP Processing Solution

Contact us for process design, equipment selection, and project quotation.