Gold CIP vs CIL Process

Key Differences · Process Selection · Proven Gold Recovery

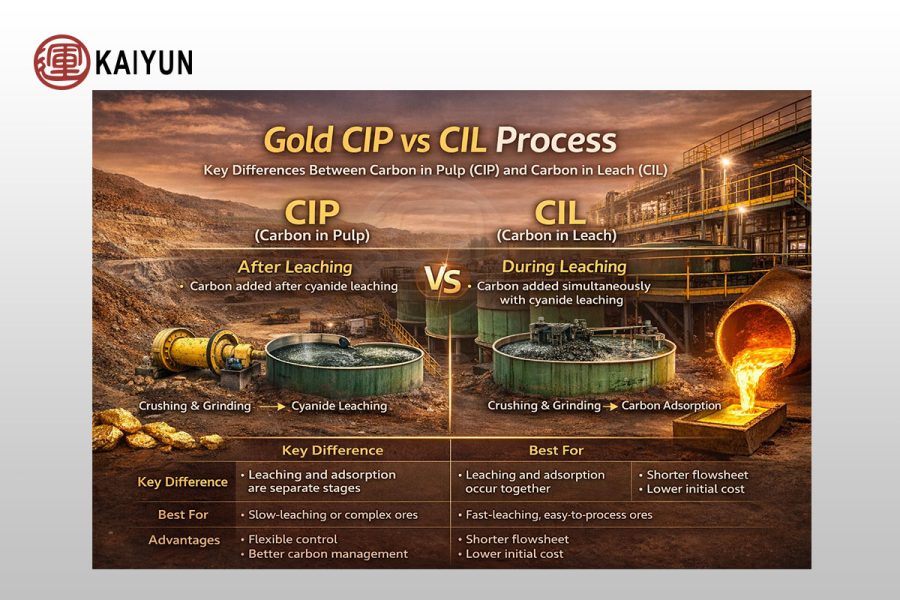

Gold CIP (Carbon in Pulp) and Gold CIL (Carbon in Leach) are two widely applied cyanide gold extraction processes.

Both can achieve high gold recovery, but the right choice depends on ore characteristics and operating conditions.

This page helps you quickly understand the difference and select the correct process for your gold project.

Screen 1|CIP vs CIL – The Core Difference

The fundamental difference is when activated carbon is added.

| Process | Carbon Addition | Process Logic |

| CIL | During leaching | Leaching & adsorption occur simultaneously |

| CIP | After leaching | Leaching and adsorption are separate stages |

👉 This difference directly affects process control, stability, and ore suitability.

Screen 2|Which Process Gives Higher Gold Recovery?

There is no fixed answer.

Gold recovery mainly depends on:

Ore type and mineralogy

Gold liberation and particle size

Leaching kinetics

Carbon activity and management

✅ With proper design, both CIP and CIL can achieve high and stable recovery rates.

👉 The ore determines the process — not the process name.

Screen 3|When to Choose CIP or CIL?

✔ Choose CIL if:

Ore leaches quickly

Oxide or low-sulfur gold ore

Low clay content

Small to medium plant capacity

Compact plant layout required

✔ Choose CIP if:

Leaching is slow

Ore composition is complex or variable

Higher clay or impurities

Medium to large-scale plant

Long-term stability is critical

👉 For complex ores, CIP offers better operational control.

Screen 4|Cost & Operation Comparison

CIL Advantages

Shorter flowsheet

Fewer tanks

Lower initial investment

CIP Advantages

Better carbon protection

More flexible process control

Lower long-term operating risk

Widely proven in African gold plants

👉 Initial cost and lifecycle cost should both be considered.

Screen 5|Complete CIP & CIL Gold Plant Solutions

We provide complete Gold CIP and CIL processing solutions, including:

Process design & engineering

Crushing and ball mill grinding systems

Leaching & adsorption circuits

Carbon elution & electrowinning

Installation guidance and technical support

Suitable for:

New gold processing plants

Plant upgrades and expansions

Gold tailings reprocessing projects

📩 Get the Right Gold Processing Solution

To recommend CIP or CIL, we need to understand your ore.

Please share:

Ore type & gold grade

Expected processing capacity

Project location

Our engineers will evaluate your project and propose a reliable, cost-effective gold recovery solution.