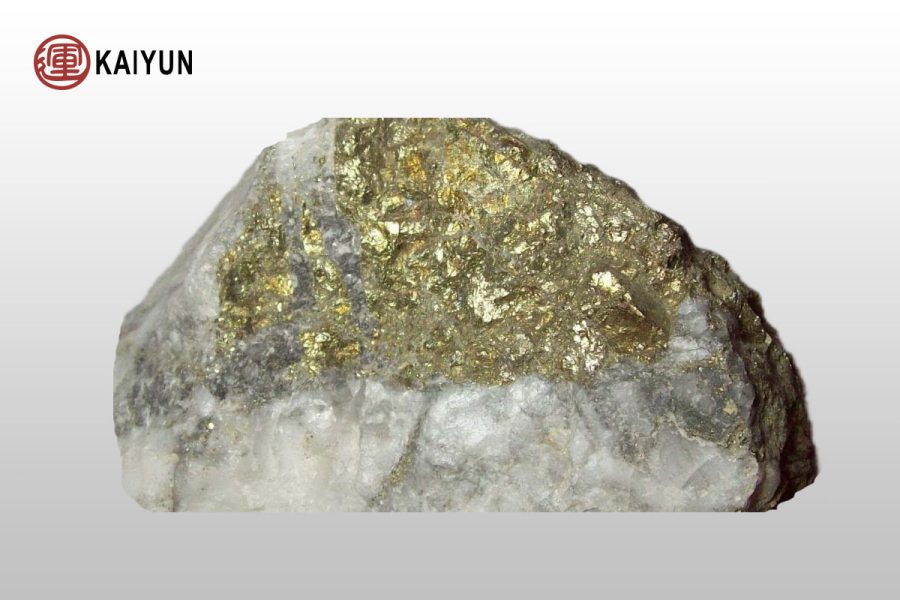

With the steady growth of global gold prices, the development of gold resources has gradually become the focus of attention of all countries. As an important mineral resource country in Southeast Asia, Vietnam has a certain amount of gold resources, especially in the northern mountainous areas and some central areas, which have great development potential. Flotation has become one of the important means of processing medium and low-grade gold ores due to its high gold recovery rate and wide range of application.

Table of Contents

What is gold flotation?

Gold flotation is a mineral processing method that uses the differences in physical and chemical properties between minerals to separate useful gold minerals from gangue minerals (such as quartz, feldspar, etc.). It is often used for gold recovery in sulfide gold ores or gold-associated sulfide ores (such as pyrite and chalcopyrite).

The main process of gold flotation

Crushing and grinding

First, crush the gold ore to a suitable particle size, and then grind it into ore pulp through a ball mill.

Purpose: Dissociate gold particles and gangue to create conditions for flotation.

Slurry adjustment and reagent addition

Add flotation reagents such as frothers, collectors, and regulators to the slurry.

Collectors make it easier for gold-containing minerals to attach to bubbles.

Flotation separation

The slurry enters the flotation machine and air is injected.

Gold-containing minerals attach to bubbles and float up to form foam products.

Gangue ores sink to the bottom and are discharged.

Concentrate treatment

The flotation concentrate is concentrated, filtered, and dried to enter the subsequent smelting stage.

Recommended main equipment suitable for the Vietnamese market

1. Jaw crusher + cone crusher

Primary and secondary crushing equipment, suitable for mountain or rock gold mining.

2. Ball mill (wet type)

High-efficiency grinding equipment with flexible production capacity, suitable for small and medium-sized gold mining enterprises.

3. Classifier or hydrocyclone

Assisted grinding stage to achieve graded control of particle size.

4. XCF/KYF flotation machine

Self-aspirated flotation machine, energy-saving and efficient, easy to maintain, suitable for Vietnam’s electricity cost-sensitive areas.

5. Concentrator + filter

Dehydrate the concentrate for subsequent transportation and smelting.

Characteristics and suggestions of the Vietnamese market

Various ore types

Vietnam is dominated by medium and low-grade sulfide gold mines, and flotation recovery is the main technical route.

Weak infrastructure

Recommend equipment models with simple structure, easy operation and low maintenance cost.

Enhanced environmental protection requirements

The flotation system needs to consider the control of reagent dosage and the matching of tailings treatment equipment.

Low labor cost and uneven training level

It is recommended that the equipment be equipped with a Chinese and English interface control system and provide remote technical support.

Conclusion

Gold flotation is currently a relatively mature gold ore dressing technology, and it has broad application prospects in Vietnam and Southeast Asia. We recommend that according to the actual situation of the mine, a modular flotation production line design be adopted, which can not only improve the recovery rate, but also facilitate later expansion or transformation.

If you need to develop a dedicated gold ore beneficiation solution, please contact us to obtain a detailed solution and equipment configuration list.