Iron ore mainly includes magnetite, hematite, siderite, and limonite. Among them, magnetite has strong magnetic properties and is the primary target for magnetic separation, while the others are weakly magnetic or non-magnetic and generally require flotation or other methods for processing.

To meet the steel industry’s demand for high-grade iron ore, Henan Kaiyun Intelligent Equipment Co., Ltd. provides efficient solutions for iron ore flotation, magnetic separation, and combined beneficiation processes—greatly improving concentrate grade and recovery rates.

1. Iron Ore Flotation Process

The flotation process separates valuable minerals from gangue based on differences in surface properties. By adding flotation reagents and air, useful minerals attach to bubbles and float to the surface for collection.

Kaiyun offers a complete flotation system, including:

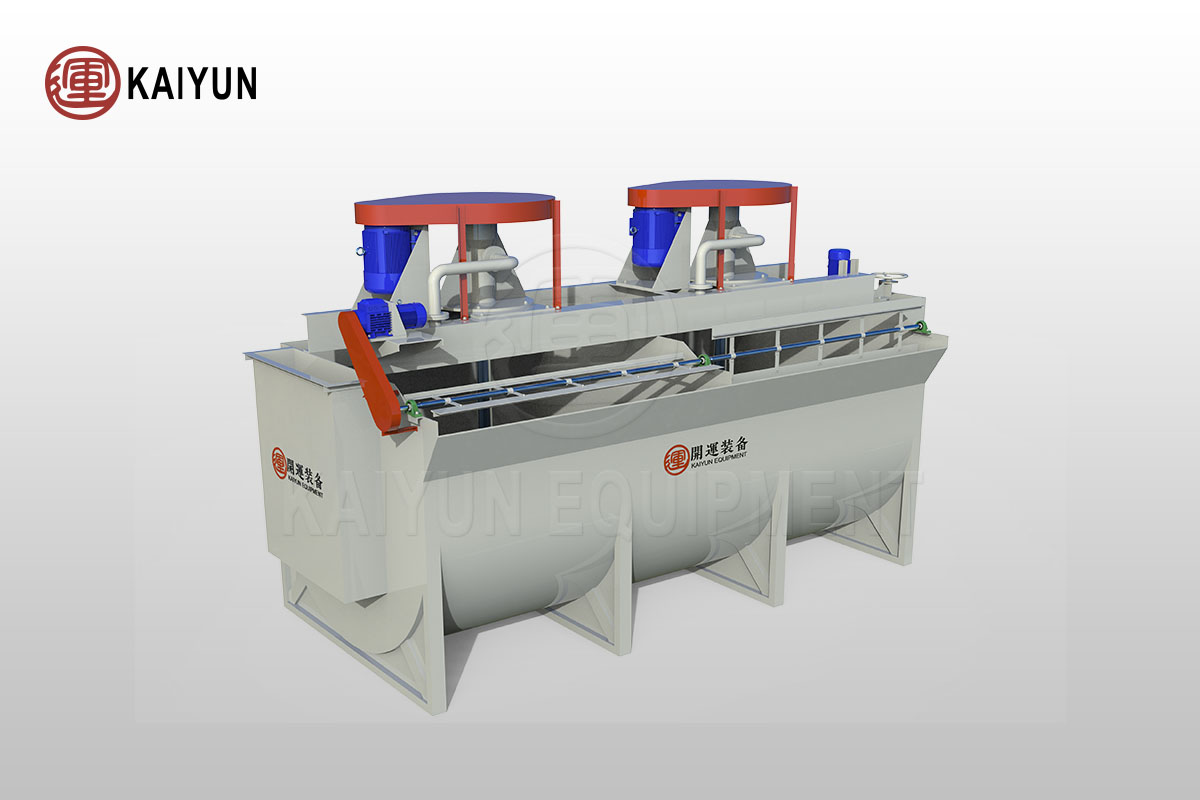

1.1 Flotation Machine

Designed for weakly magnetic or non-magnetic iron ores. Uses air and reagents to separate useful minerals from the slurry. High efficiency and low energy consumption.

1.2 Mixing Tank

Used for uniform slurry mixing and reagent conditioning. Simple structure, wear-resistant, and enhances flotation performance.

1.3 Bubble Generator

Provides stable and fine bubbles to improve mineral-bubble attachment and flotation efficiency.

Key parameters such as slurry concentration, mixing intensity, air flow, and reagent dosage can be precisely and intelligently controlled to optimize recovery.

2. Iron Ore Magnetic Separation Process

Magnetic separation relies on differences in magnetic properties between ore minerals and gangue. Based on ore type, we offer a range of magnetic separation equipment:

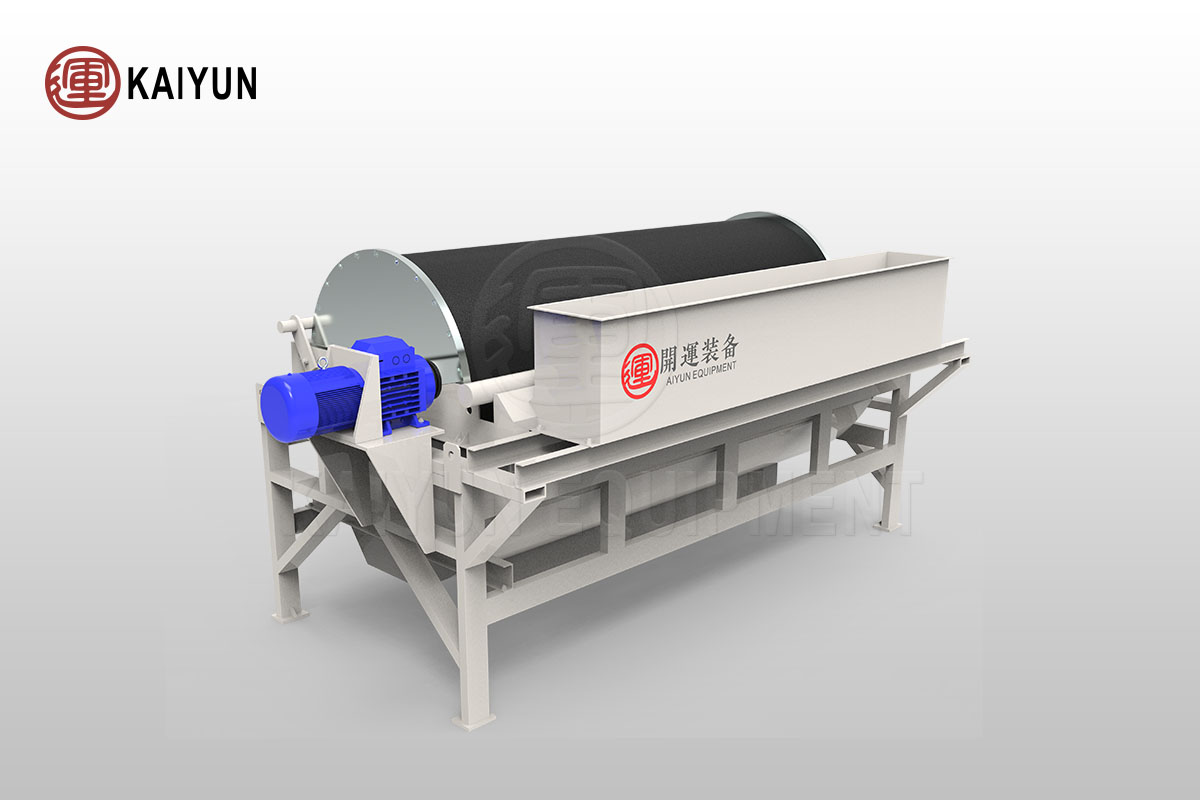

2.1 Dry Magnetic Separator

Suitable for separating coarse-grained magnetic minerals in dry conditions. Easy to operate and highly adaptable.

2.2 Wet Magnetic Separator

Performs separation in slurry form, ideal for medium to fine-grained ore. Offers high separation efficiency.

2.3 Permanent/Electromagnetic Magnetic Separators

Permanent magnets are energy-efficient and stable, suitable for standard ores; electromagnetic types offer adjustable magnetic fields, suitable for complex or low-grade ores.

Parameters such as magnetic field strength, feed rate, and slurry density are fully adjustable to ensure stable performance, low energy consumption, and high output.

3. Combined Flotation + Magnetic Separation Process

For complex and refractory iron ores, Kaiyun recommends a combined flotation and magnetic separation process. This integrated approach ensures efficient multi-mineral separation.

Key advantages:

Significantly improves concentrate grade and recovery.

Effectively removes impurities.

Reduces energy consumption and production costs.

Equipped with intelligent control systems to monitor and adjust reagent dosage, magnetic field strength, slurry concentration, pH, and more—ensuring optimal process performance.

4. Equipment Maintenance & Technical Support

Pilot testing services and customized process design.

On-site equipment installation, commissioning, and staff training.

Regular equipment inspections and maintenance to ensure stable operation.

Henan Kaiyun Intelligent Equipment Co., Ltd. is committed to delivering efficient, intelligent, and energy-saving iron ore beneficiation solutions.

Feel free to contact us for detailed process designs and equipment selection advice!