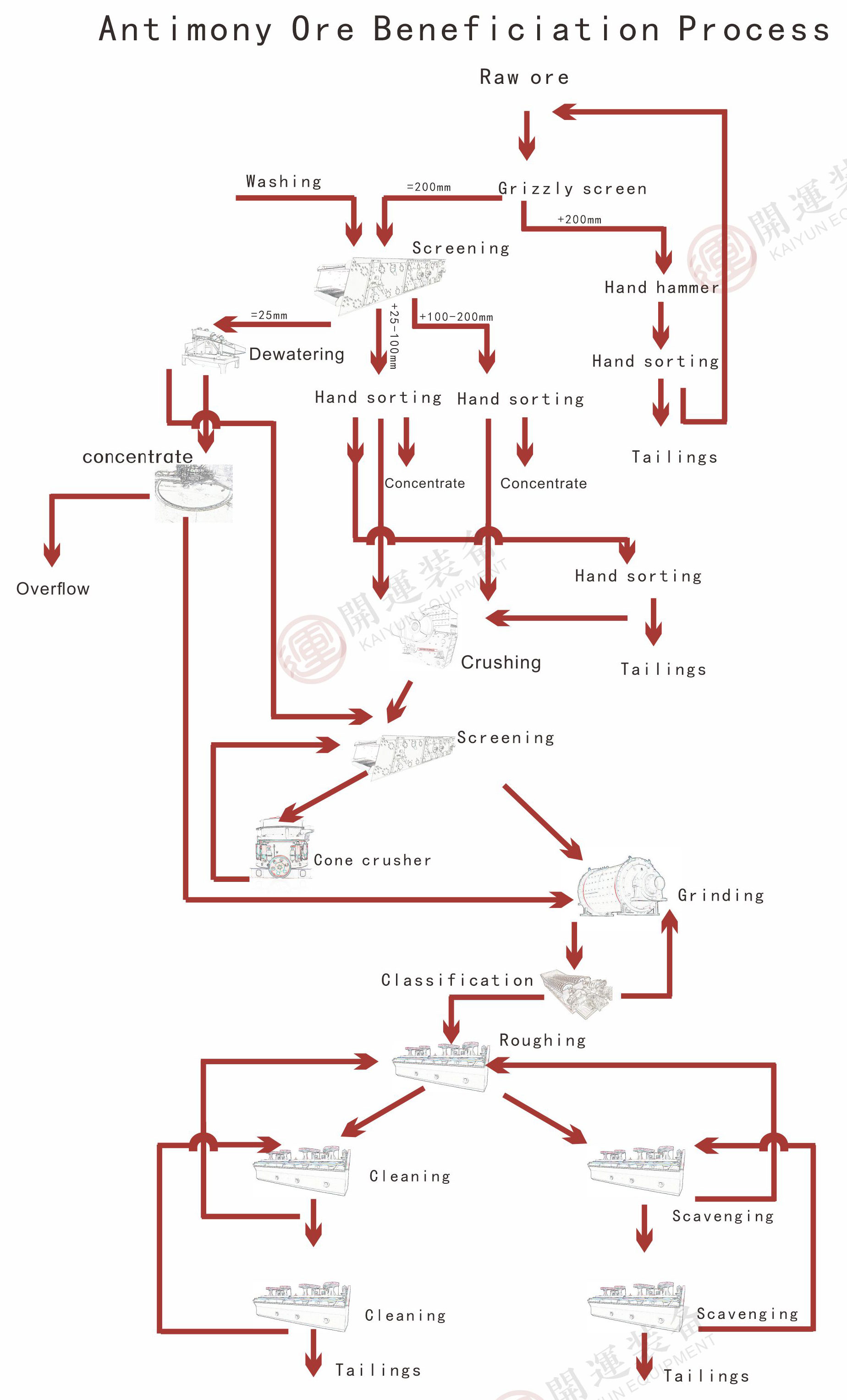

Process introduction

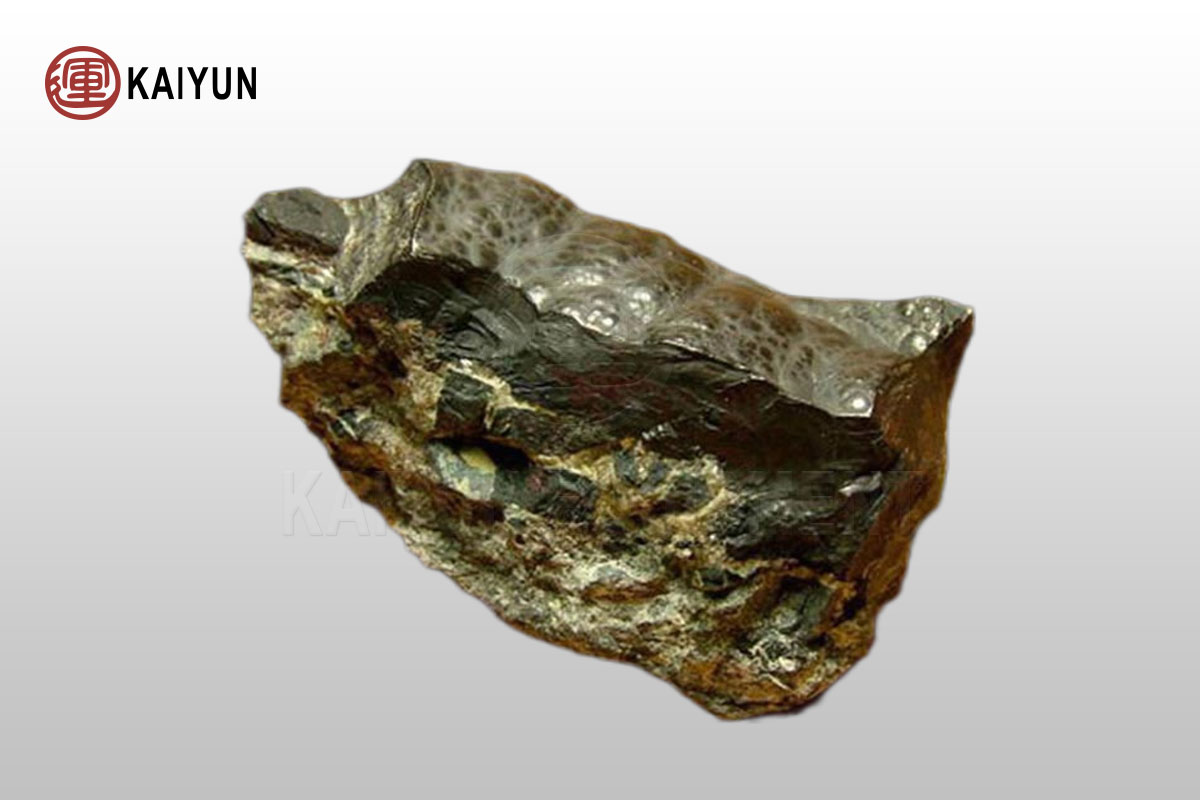

The specific gravity of antimony ore is much greater than that of gangue, so it can be separated by gravity separation. Gravity separation is efficient, energy-saving and environmentally friendly, and can also enrich low-grade ore in advance. After gravity separation, antimony ore is purified by flotation. Therefore, gravity separation and flotation combined process is usually used to separate antimony ore.

Application field

Kaiyun gravity separation and flotation combined process is suitable for all types of antimony ore.

Table of Contents

Process details

1. Preparation before selection

– The hand-selected raw ore is coarsely crushed and finely crushed to control the ore particle size below 30mm.

– The screening classification is divided into three particle sizes of 8-30mm, 2-8mm and 0-2mm.

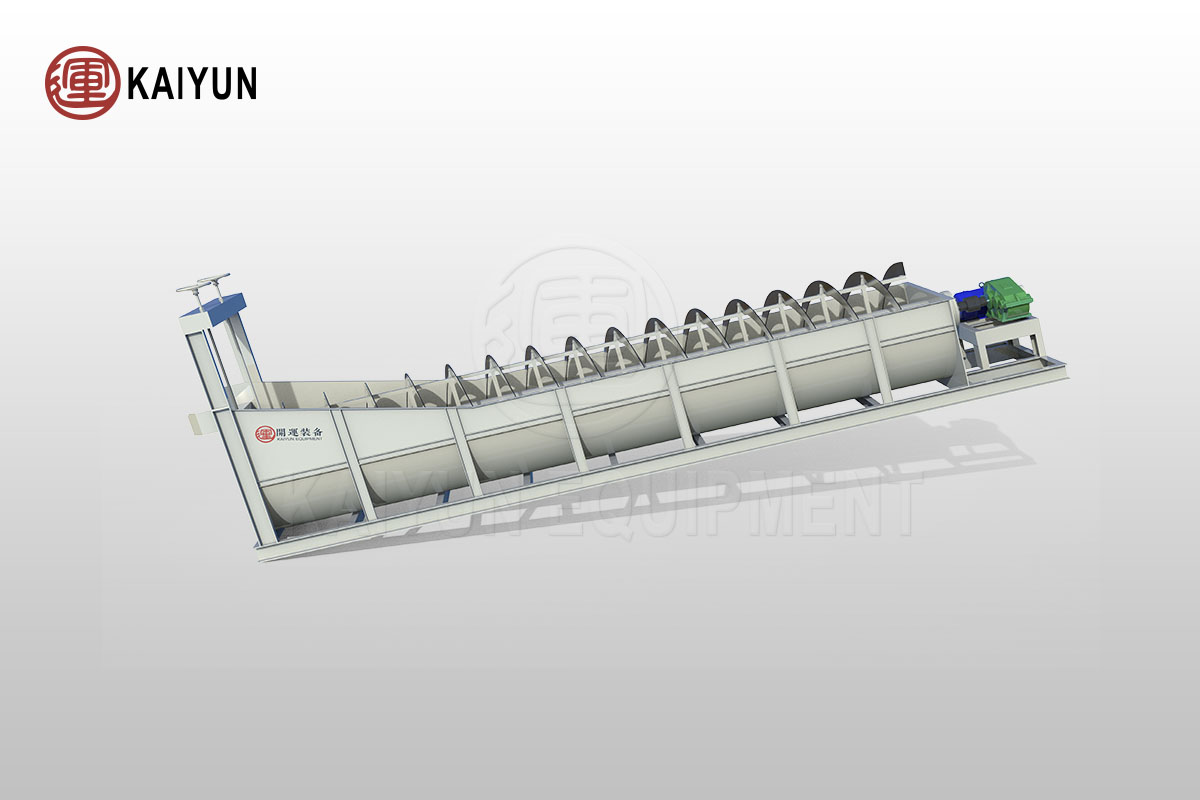

2. Gravity separation

– The three particle sizes of ore after classification enter different jigs for gravity separation.

– 8-30mm particle size enters AM30 jig;

– 2-8mm particle size enters LTA1010/2 jig;

– 0-2mm particle size enters sawtooth wave jig.

– The concentrate obtained by gravity separation is mixed and enters gravity separation concentrate area.

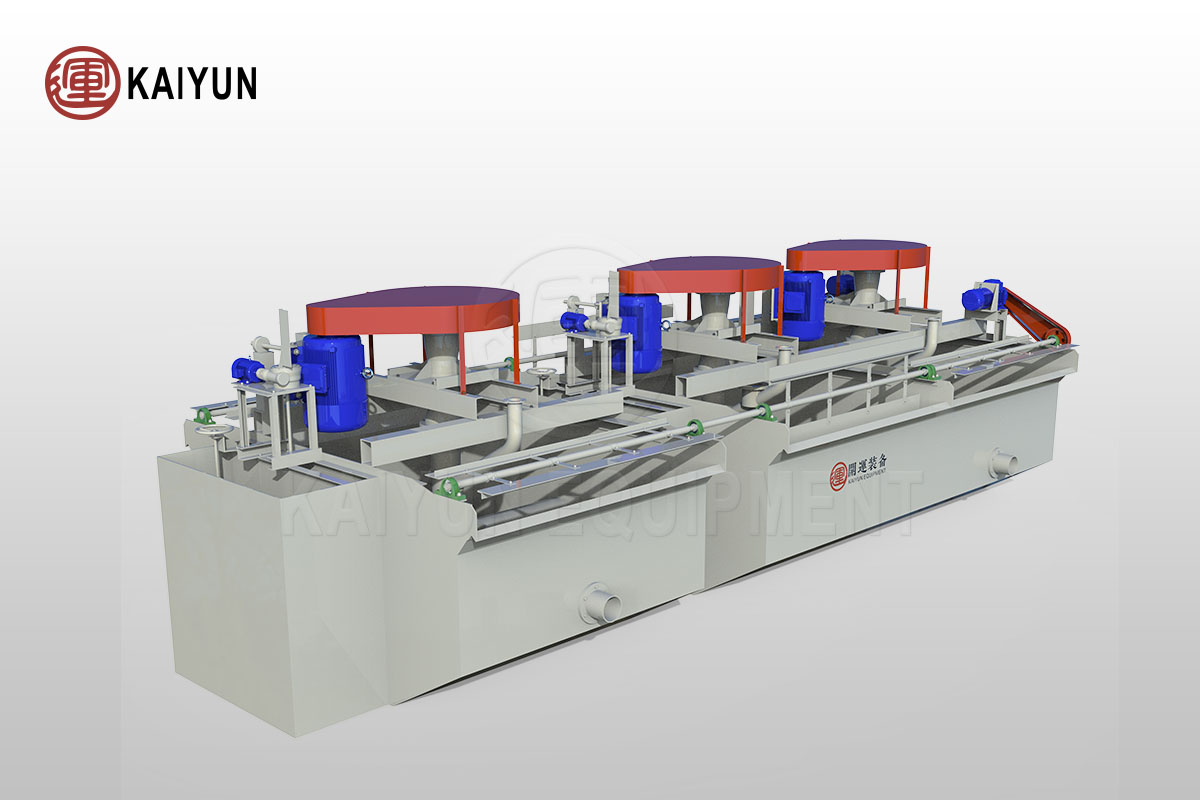

3. Flotation

– After the gravity separation process, a flotation process is set up to grind, grade, stir and float the gravity separation tailings.

– The flotation process adopts a one-rough, three-fine and two-sweep process.

– Flotation obtains high-grade antimony flotation concentrate.

– The flotation tailings are re-selected by shaking table gravity separation, and fine-grained antimony oxide is recovered to obtain high-grade antimony concentrate and tailings.

4. Hand selection

– For block-shaped rich ores with particularly coarse embedded particle size, a hand selection process is added to the crushing process to manually select the block-shaped rich ores.

– The hand-selected tailings enter the gravity separation process again.

Process flow chart