Introduction

Chromium ore dressing process is mainly a gravity separation process, which is a method of separating minerals according to different mineral densities. The equipment used includes jigs, shaking tables, spiral polarizers, centrifugal concentrators and spiral chutes. Sometimes, the gravity separation concentrate also needs to be re-selected with weak magnetic separation or strong magnetic separation to further improve the grade of chromium concentrate and the chromium-iron ratio.

Application Field

The selection of chromium ore dressing process is closely related to the physical and chemical properties of chromium ore. Because chromium ore has weak magnetic properties, with the continuous advancement of high-intensity magnetic separation technology, the process of using high-intensity magnetic separation to purify chromium ore has become very mature. And because the magnetic separation process has less pollution to the environment, the chromium ore magnetic separation process has been promoted and applied in major mines and concentrators.

Table of Contents

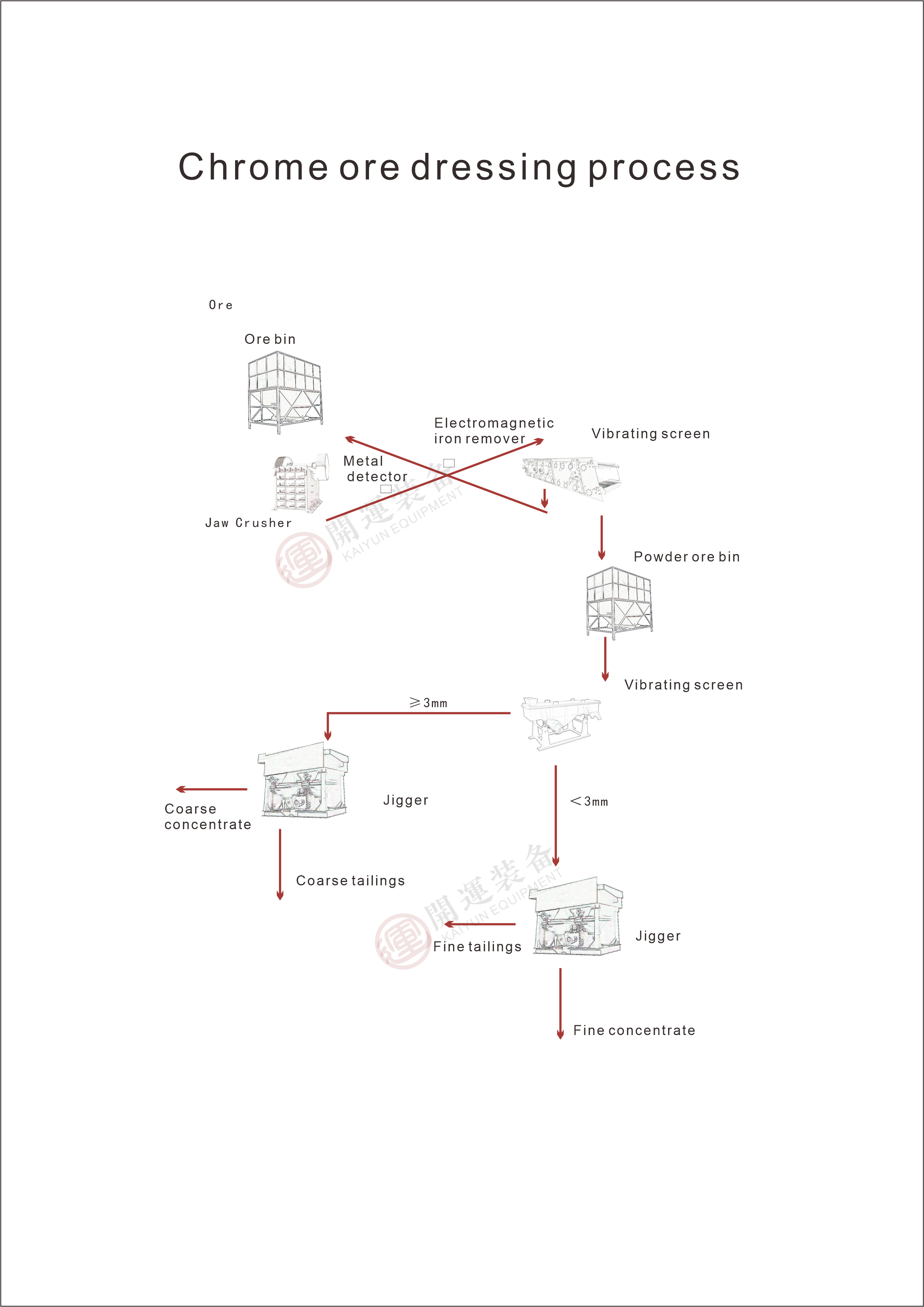

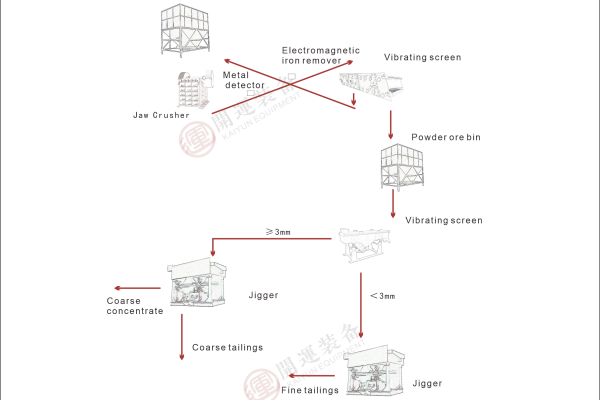

Process Flow

Mineral processing methods

For chromium ore dressing, there are many methods such as gravity separation, flotation, and magnetic separation. We will give the final mineral processing method based on the ore analysis report and mineral processing test report.

Gravity separation

The main mineral processing process of gravity separation is as follows: the chromium ore fines that have been ground to a reasonable fineness are washed and graded by a spiral classifier by taking advantage of the different specific gravity of solid particles and the different precipitation speeds in the liquid. The materials are then washed and sorted by a jig and a shaking table, and transported to a spiral chute to sort fine-grained ore powder.

Flotation/Magnetic separation

After screening, it is sent to a flotation machine or a magnetic separator, and the concentrate entering the flotation is dehydrated.

Drying

The dehydrated concentrate is further sent to a dryer for drying to obtain a usable dry concentrate or secondary grinding to continue extracting minerals.

Process Flow Chart