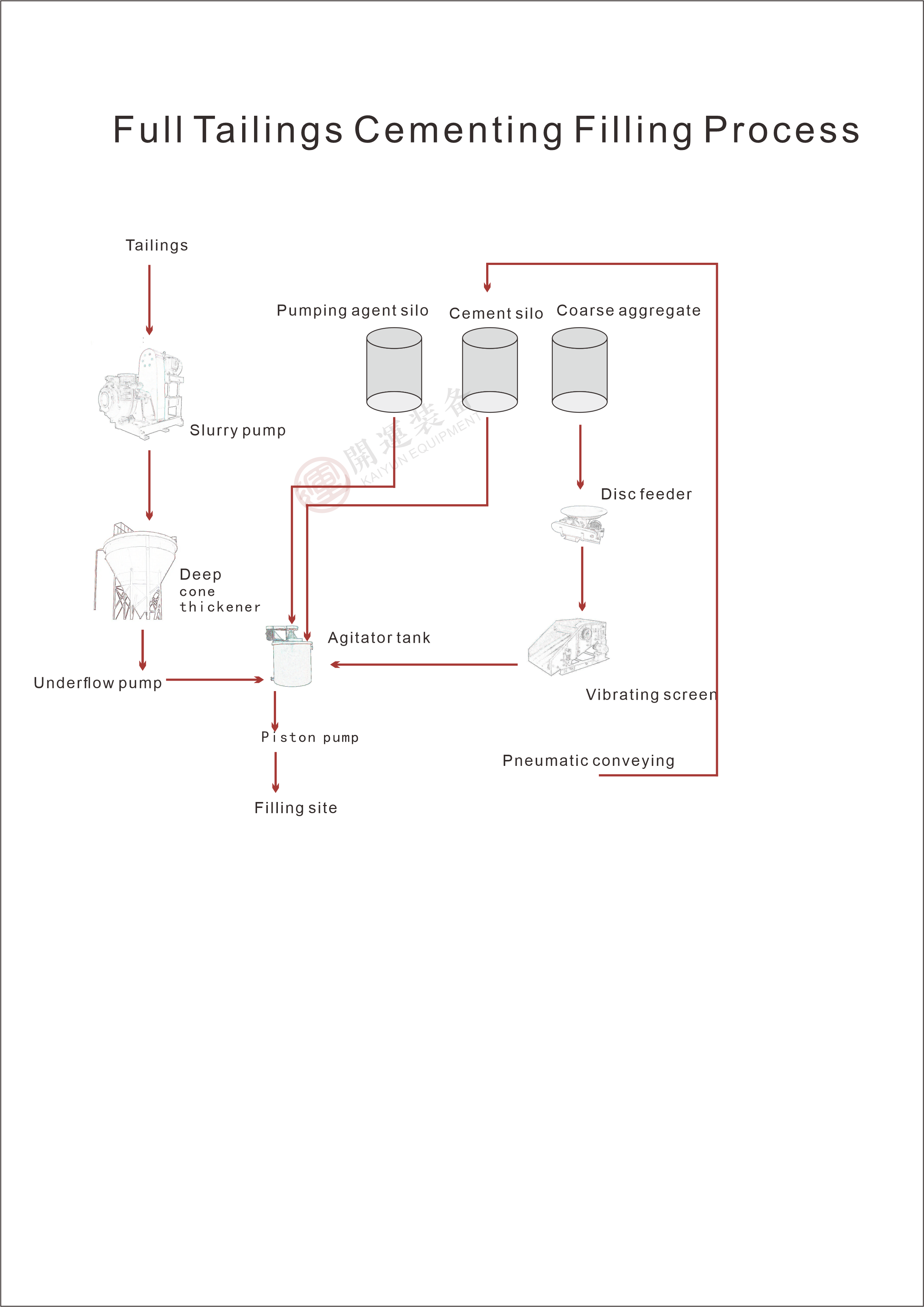

Full Tailings Cementing Filling Process Introduce

The full tailings cementing filling process is based on the theories of physical chemistry and colloid chemistry. It directly uses the tailings slurry from the dressing plant, and after the thickener and sand bin are settled and dehydrated, the full tailings and a certain proportion of cement and water are synthesized into a homogeneous cementing filling material through a double-shaft blade mixer and a high-speed activated mixer, and the filling material is filled into the mining area through a pipeline.

The parameters such as tailings flow, cement flow, water addition amount and the concentration of the synthetic filling slurry are controlled by an automatic control system.

Full tailings cementing filling is to make full use of tailings resources and realize waste-free mining in mines. At the same time, it is also to regard tailings as a prospective resource and store it underground. When the technology and economy are mature in the future, it will be redeveloped and utilized to meet the needs of national economic development. It is a new technology in the modern mining industry that is conducive to the sustainable development of the mining industry.

Table of Contents

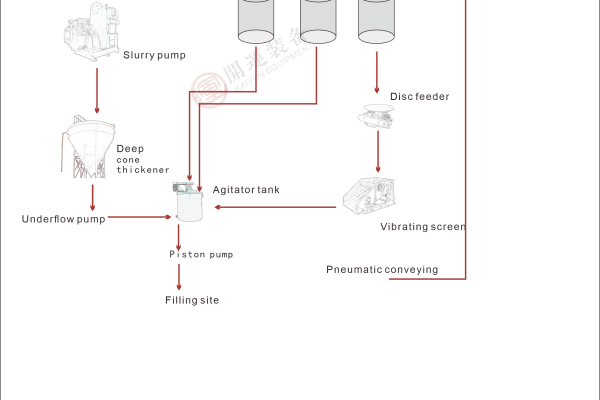

Full Tailings Cementing Filling System

The full tailings cementing filling system mainly consists of four parts: dehydration system, mixing system, pipeline transportation system and automatic detection and adjustment system.

Application of Full Tailings Cementation Filling Technology

By using full tailings to effectively fill the goaf, the environmental and safety problems caused by mineral resource mining can be fundamentally solved, and mineral resources can be fully recovered, which is of great significance to promoting the coordinated development of mining industry, resources, environment, safety and economy.

1. Reduce the discharge of solid waste in mines, realize tailing-free mine production, avoid the industrial occupation of tailings, save the land acquisition, construction and maintenance costs of tailings ponds, and also avoid the possible pollution of the atmosphere, water bodies and soil, which is of great significance to the protection of the surface ecological environment.

2. It can effectively prevent the obvious movement of rock formations, prevent surface collapse, realize “three down” safe mining and give priority to mining the lower or lower plate rich ore without causing damage to mineral resources, and protect prospective resources.

3. It can effectively control ground pressure, control local and regional rock formation fragmentation damage, improve the safety of mining operations, reduce the risk of roof collapse accidents in the mining field, and alleviate the threat of rock bursts during deep mining.

4. The tailings filling can safely recover the residual ore, thereby increasing the ore recovery rate and improving the economic benefits of the mine.

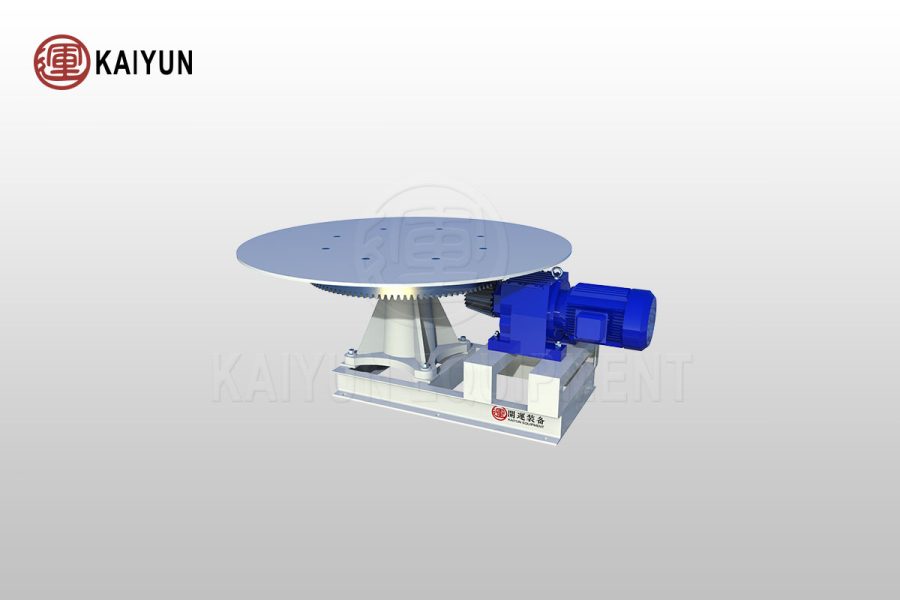

Process Flow Chart