Process Introduction

Carbon in Leach (CIL) is a gold extraction process based on the linkage of cyanide leaching and activated carbon adsorption, which is widely used in the industrial production of low-grade gold mines (Au content ≥ 0.5 g/t). Its core process includes four modules: cyanide leaching-carbon adsorption-desorption electrolysis-activated carbon regeneration, which can achieve a gold recovery rate of 90%-98%, and the comprehensive cost is 15%-30% lower than that of traditional processes.

The CIL process achieves a balance between high efficiency and economic efficiency in gold extraction through the synergistic effect of cyanide leaching and carbon adsorption. In the future, with the tightening of environmental protection regulations and technological progress, the process will continue to upgrade to low cyanide and intelligent direction, providing sustainable development solutions for the global gold mining industry.

Table of Contents

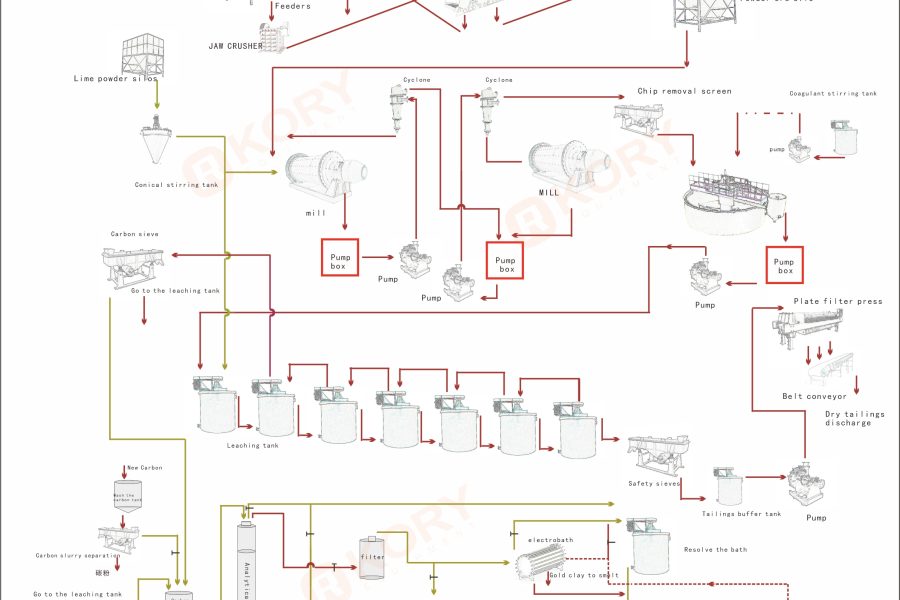

Process Flow

Step 1: turning ore into “gold soup”

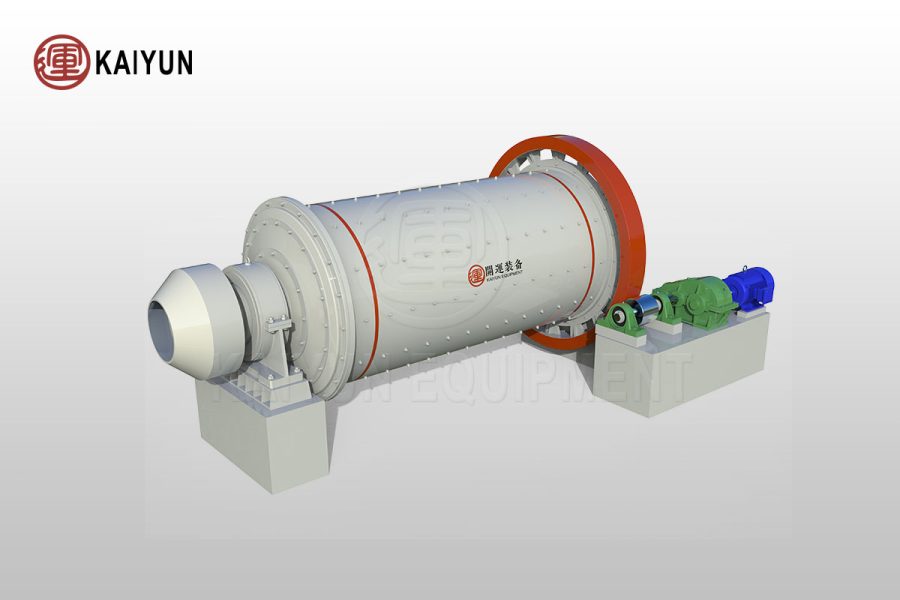

Crushing and grinding:

The gold ore is first “smashed” into small pieces by the crusher, and then enters the ball mill to be ground into fine powder (similar to the coarseness of flour). This step is to fully expose the gold particles for subsequent dissolution.

Slurry preparation and cyanide leaching:

The ground mineral powder is mixed with water to form “mud”, and a small amount of cyanide solution (a chemical reagent that can dissolve gold) is added. In a large stirring tank, gold reacts with cyanide to become a “gold solution” that is soluble in water – this step is like boiling a pot of “gold soup”.

Step 2: “Gold-absorbing sponge” is deployed!

Activated carbon adsorbs gold:

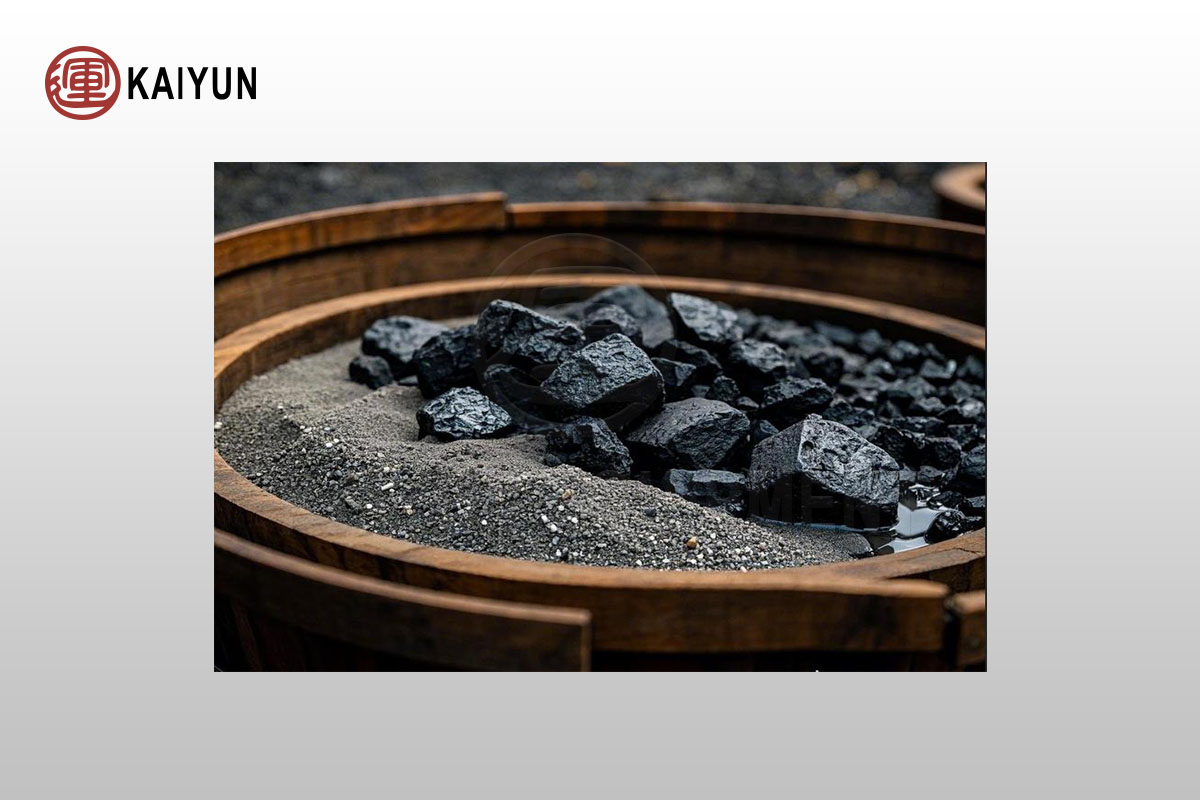

Activated carbon particles (black particles with small holes on the surface) are put into the leaching tank. These activated carbons, like “gold-absorbing sponges”, firmly adsorb the gold dissolved in water on the surface.

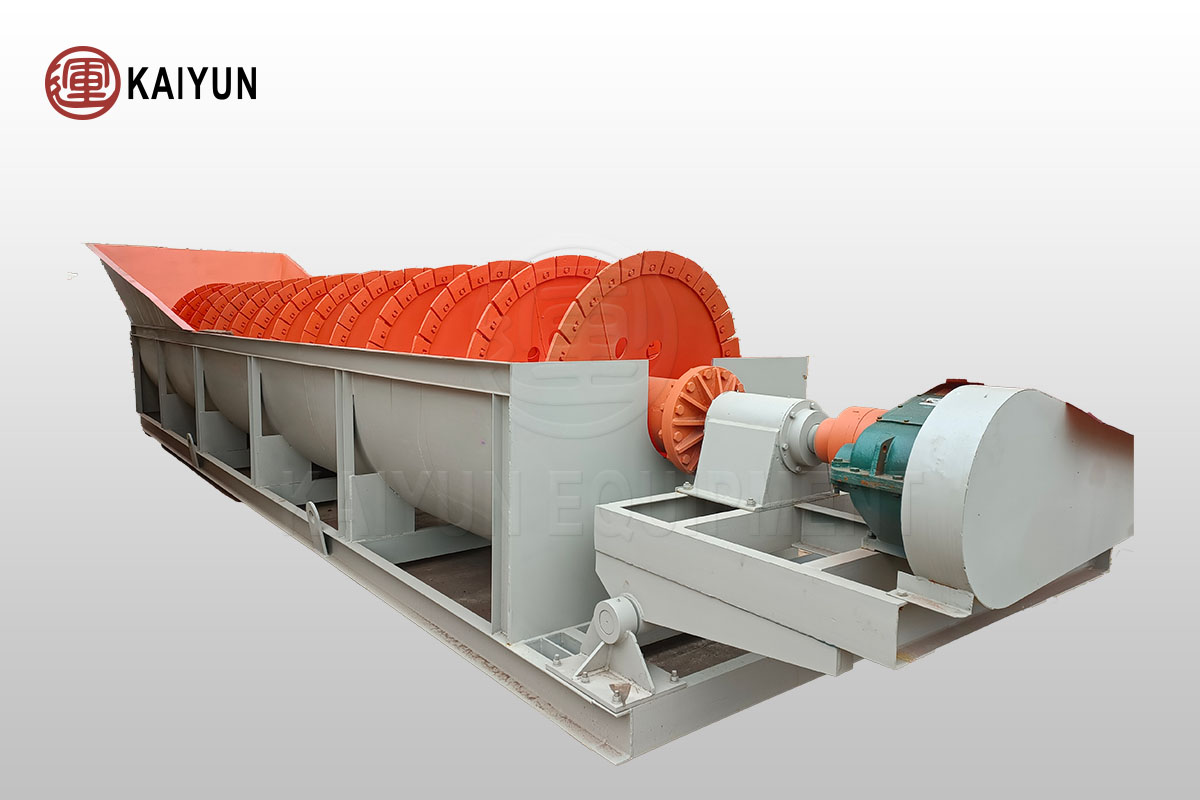

“Sponge” and slurry separation:

The activated carbon that adsorbs gold will be screened out, and the remaining slurry (no longer containing gold) will enter the tailings pond for treatment to ensure environmental safety.

Step 3: Squeeze the gold out of the “sponge”

High-temperature desorption:

The gold-loaded activated carbon is sent to the desorption tower and “washed” with a high-temperature alkaline solution. The gold falls off the activated carbon and dissolves again in the liquid. This step is like “squeezing” a sponge full of ink with hot water.

Electrolytic purification:

The gold-containing solution enters the electrolytic cell, and through the action of electric current, the gold is reduced to metal and deposited on the cathode plate to form high-purity gold mud (purity can reach more than 99%).

Step 4: “Sponge” recovery and recycling

The used activated carbon is regenerated at high temperature to restore its adsorption capacity and can be put into production again, greatly reducing costs.

Process advantages

High gold recovery rate: more than 95% of the gold in the ore can be extracted, which is more efficient than traditional methods.

Simple and stable operation: suitable for processing low-grade ores (gold content as low as 1 gram per ton of ore can also be economically recovered).

Strong adaptability: can be combined with other processes (such as flotation) to deal with complex ore types.

CIL vs. CIP

CIL (carbon leaching method): activated carbon is directly added to the leaching tank, and adsorption and leaching are carried out simultaneously.

CIP (carbon-in-pulp method): first leaching gold, and then adsorbing with activated carbon alone.

Simple summary: CIL saves more time, and CIP is more suitable for ores with many impurities.

Production flow chart