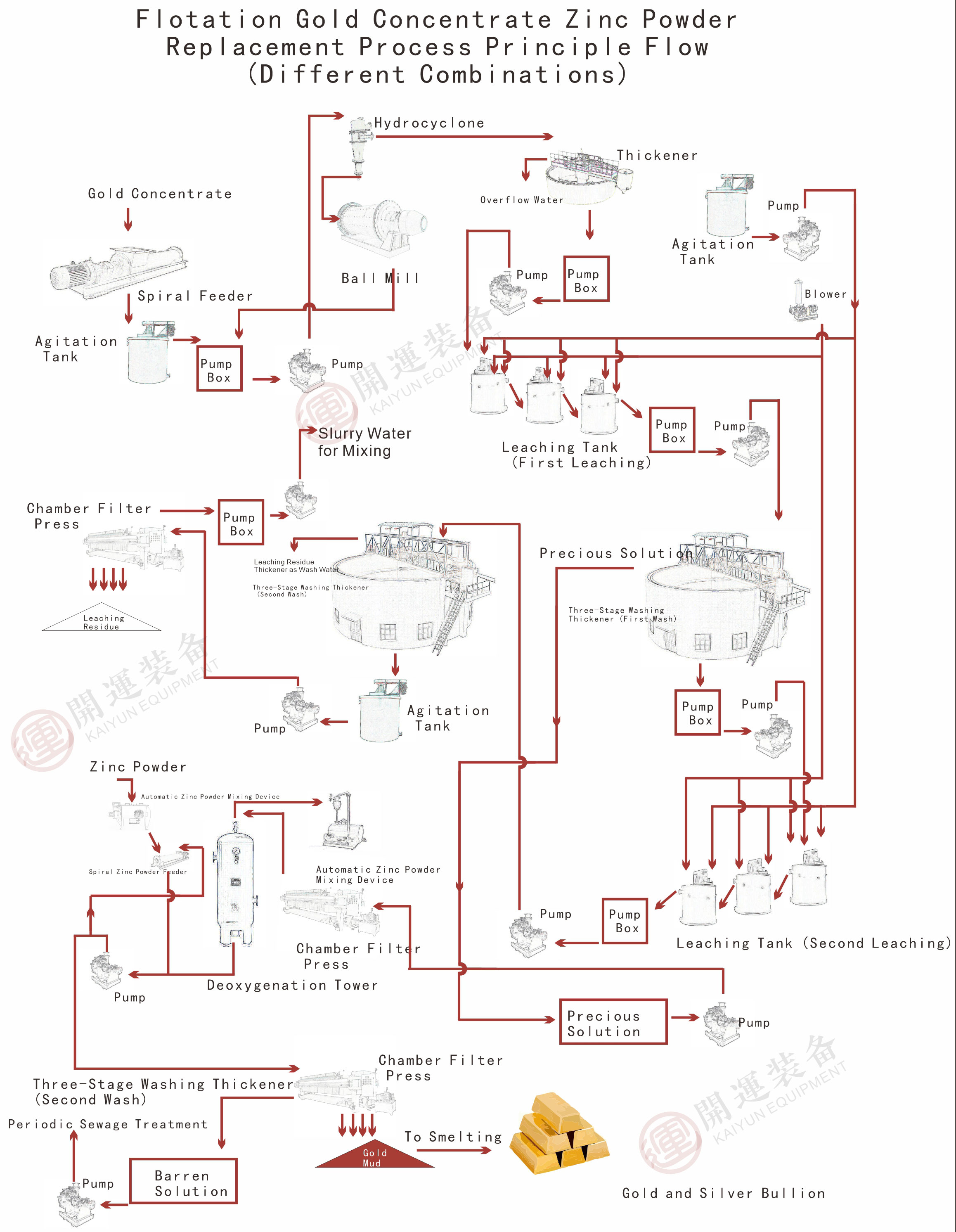

Process Flow Overview

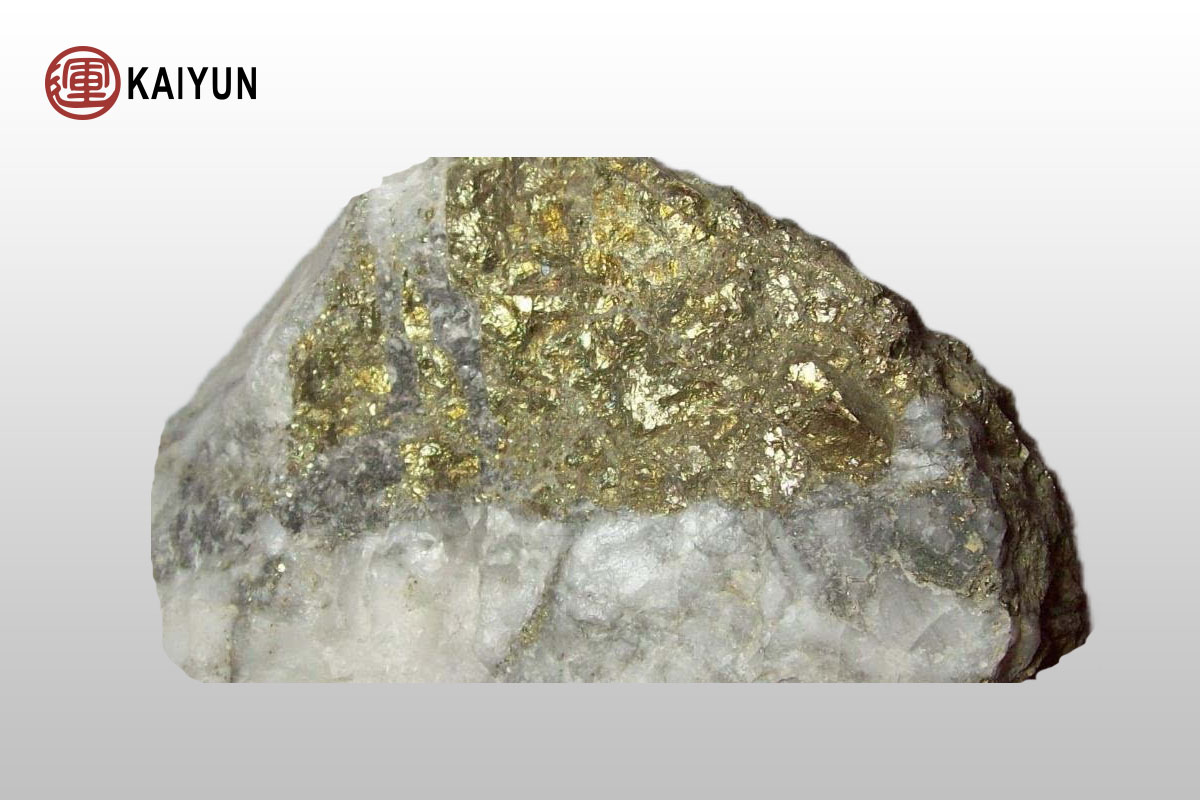

The Gold Carbon in Pulp(CIP)process, a highly efficient and environmentally friendly gold extraction technique, involves the adsorption of gold by activated carbon directly from cyanide slurry. The gold is then extracted through desorption and electrolysis processes. This method is known for its simplicity, low cost, and excellent environmental performance.

Gold Carbon in Pulp(CIP)process includes seven main stages: slurry preparation, cyanide leaching, activated carbon adsorption, gold-loaded carbon desorption, gold mud electrolysis, gold-depleted carbon recycling, and leached slurry treatment.

Table of Contents

Application Fields

This process is suitable for two types of ores: flotation gold concentrates or amalgamated and gravity separation tailings, and argillaceous oxidized ores. It is widely used in gold ore processing production lines.

Detailed Process Description

Slurry Decontamination

Before adsorption, impurities such as wood chips in the slurry must be removed to prevent gold adsorption and clogging of the carbon screens.

Leaching and Adsorption

Activated carbon is added to the leaching tank, where it adsorbs gold from the slurry, forming gold-loaded carbon. After adsorption, a carbon screen is used to separate the activated carbon from the slurry.

Efficient Low-Consumption Rapid Desorption and Electrolysis System

Efficiency

When the gold content in the loaded carbon reaches 3000g/t, the desorption rate can exceed 96%.

Speed

Desorption and electrolysis can reach temperatures of 150°C and pressures up to 0.5 Mpa, significantly shortening desorption time.

Low Consumption

Due to the rapid process, power consumption is only 1/2 to 1/4 of conventional systems.

Cyanide-Free

The desorption solution does not require sodium cyanide, reducing costs and pollution.

High Grade

The gold mud has a high gold content, eliminating the need for re-electrolysis and making extraction easier.

Automatic Control

Equipped with liquid level, temperature control systems, and automatic control functions.

Safety

Features triple safety protection measures to ensure operational safety.

Smelting

The gold mud, after simple acid washing to remove impurities, can be directly smelted into gold ingots.

Process flow chart