What is the CIL Process?

Gold CIL (Carbon-in-Leach) Process is a highly efficient gold extraction process used in modern gold processing plants. Compared to traditional methods, the CIL process integrates leaching and adsorption into a single step, improving gold recovery, reducing processing time, and lowering operational costs.

Our modular and customizable Gold CIL Process Plants are widely used in Africa, Asia, and South America for both oxide and sulfide gold ores.

Gold CIL (Carbon-in-Leach) is a gold cyanidation process

1.Gold-bearing ore is finely crushed and ground;

2.The ore is mixed with cyanide solution;

3.Activated carbon is added directly to the leaching tanks;

4.Gold is simultaneously dissolved and adsorbed onto carbon;

5.Gold-loaded carbon is separated and processed in a desorption system;

6.Pure gold is recovered via electrowinning and smelting.

✅ By combining leaching and adsorption, CIL improves reaction efficiency and minimizes gold loss.

Table of Contents

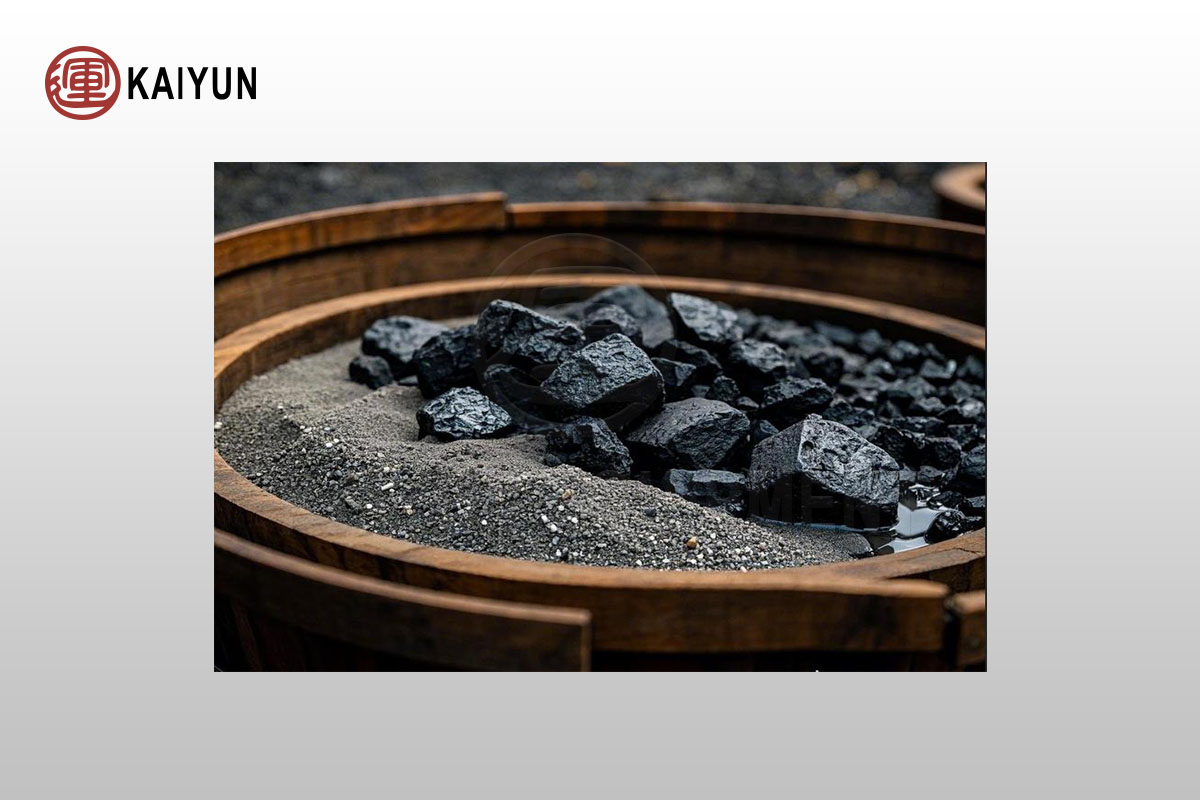

Suitable for the Following Ores

Refractory gold ores (with roasting or bio-oxidation)

Oxidized gold ores

Sulfide-bearing gold ores (after pre-treatment)

Flotation tailings

Heap leaching residues

CIL Plant Equipment List

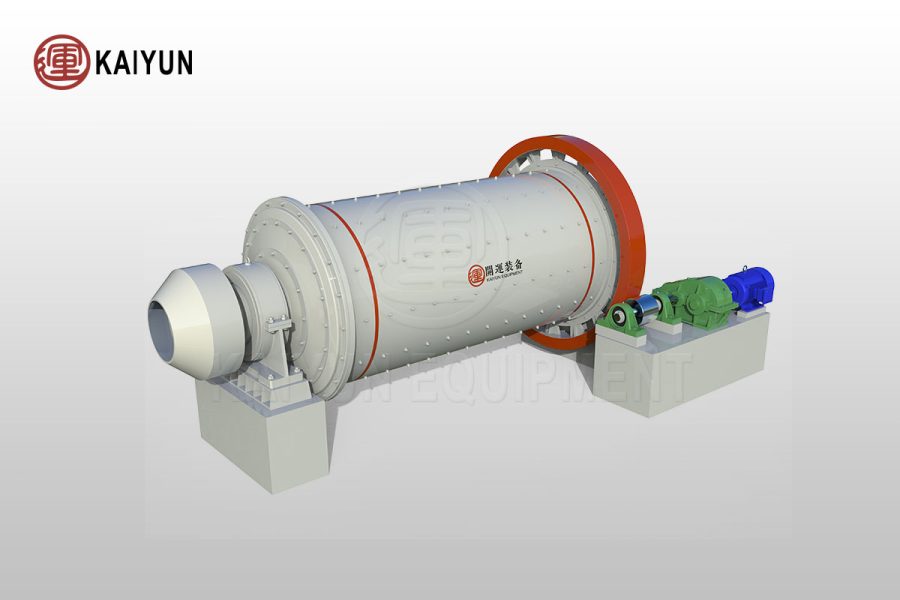

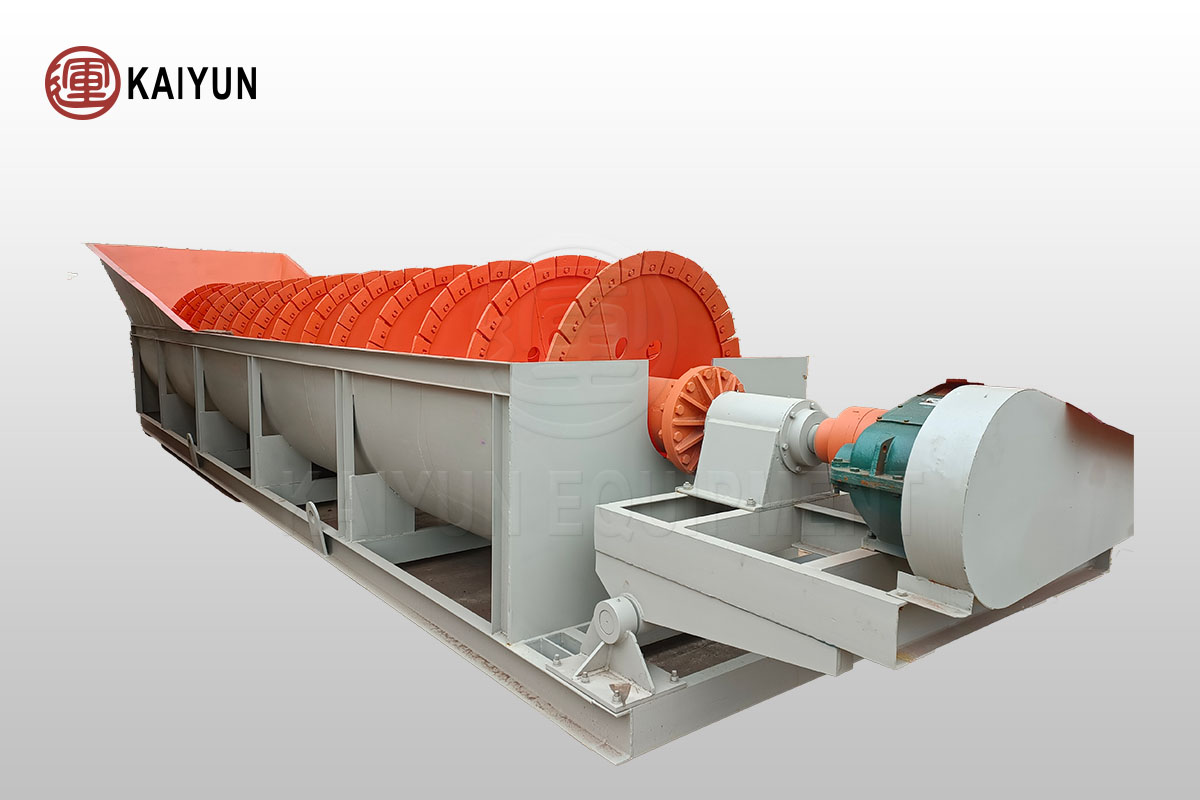

| Equipment | Function |

| Jaw Crusher / Hammer Crusher | Primary ore crushing |

| Ball Mill / Grinding Mill | Grinding to required fineness |

| Slurry Pump / Classifier | Slurry transportation and classification |

| Leaching & Adsorption Tanks | Combined cyanidation and carbon adsorption |

| Desorption & Electrolysis Unit | Gold separation from carbon |

| Gold Smelting Furnace | Final gold bullion production |

| Thickener / Filter Press | Tailings dehydration and water recycling |

Benefits of Our Gold CIL Process

Higher Recovery Rate

95–99% depending on ore grade.

Shorter Processing Cycle

Leaching and adsorption in a single flow.

Compact Plant Layout

Save space and civil construction cost.

Customizable Design

For 100–5000 TPD capacity.

Eco-Friendly

Tailings detoxification and wastewater reuse options.

Full EPC Service

From lab testing to on-site commissioning.

CIL vs. CIP

CIL (carbon leaching method): activated carbon is directly added to the leaching tank, and adsorption and leaching are carried out simultaneously.

CIP (carbon-in-pulp method): first leaching gold, and then adsorbing with activated carbon alone.

Simple summary: CIL saves more time, and CIP is more suitable for ores with many impurities.

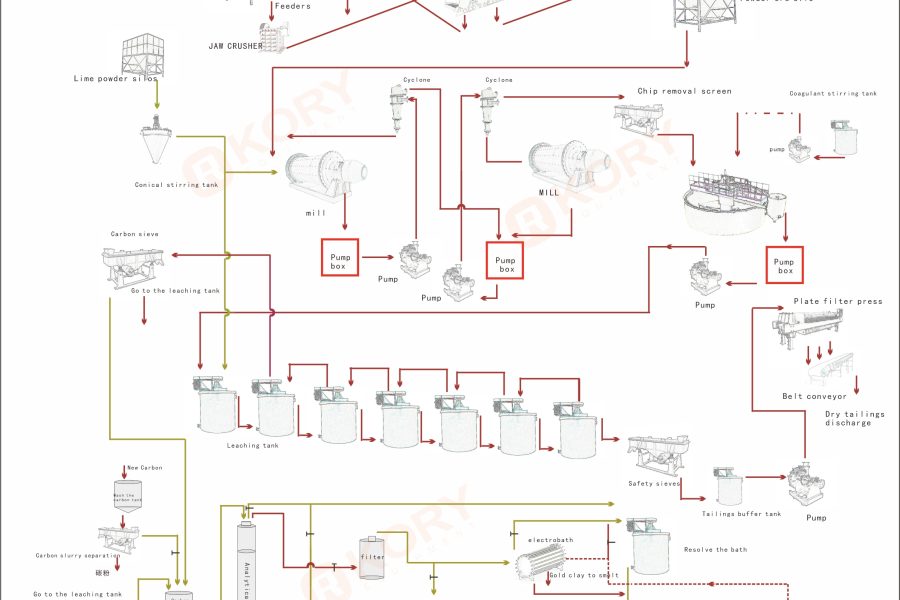

Production flow chart

Why Choose Our CIL Solution?

20+ years of experience in gold mineral processing.

Designed for both fixed plants and containerized mobile units.

Turnkey solution: from sample testing, flowchart design, equipment manufacturing to overseas installation.

Serving mining projects in Ghana, Sudan, Tanzania, Indonesia, Nigeria, Peru, and more.

📞 Get in touch today for a free consultation and tailored CIL plant solution based on your ore sample.