What is the CIP Process?

The Gold CIP process, a highly efficient and environmentally friendly gold extraction technique, involves the adsorption of gold by activated carbon directly from cyanide slurry. The gold is then extracted through desorption and electrolysis processes. This method is known for its simplicity, low cost, and excellent environmental performance.

The Gold CIP (Carbon-in-Pulp) Process method involves:

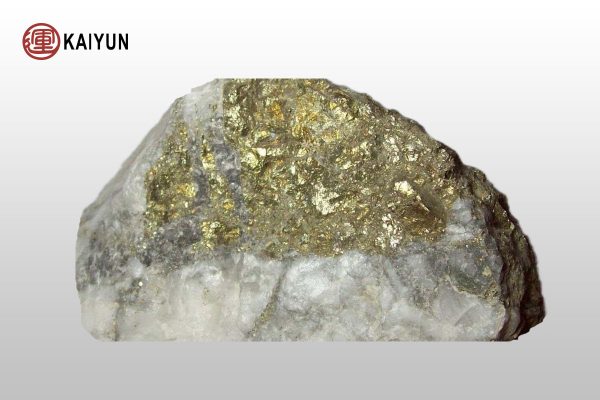

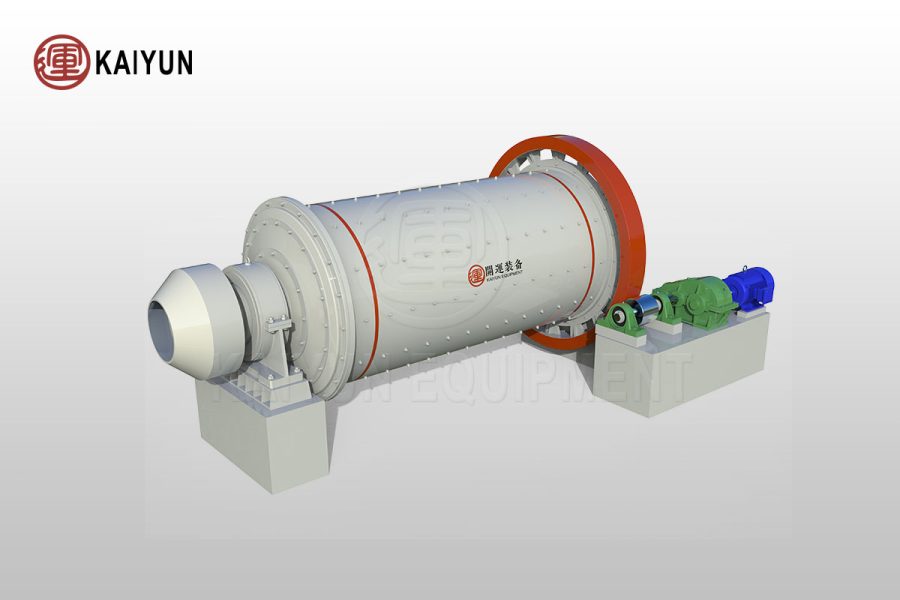

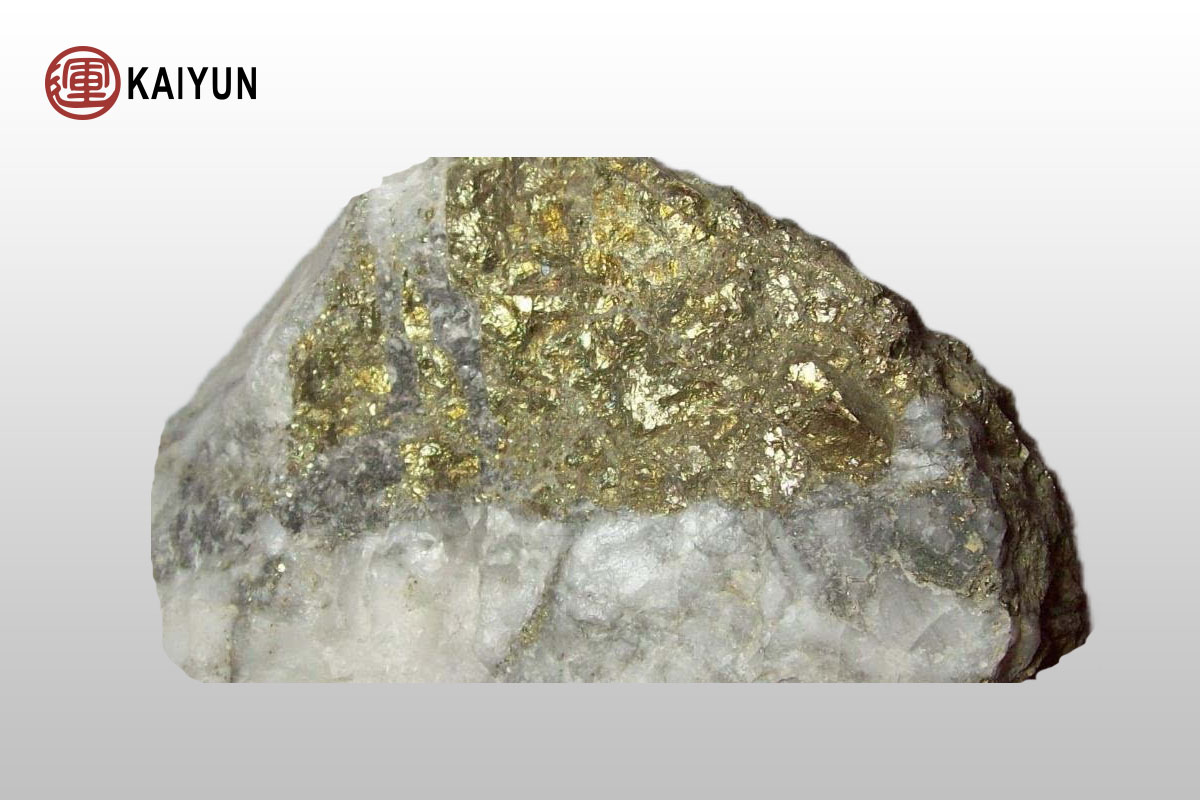

Crushing and grinding the gold ore to a fine particle size;

Leaching the ore in a cyanide solution to dissolve the gold;

Adsorbing the gold onto activated carbon;

Desorbing the gold from carbon;

Electrowinning to recover solid gold;

Smelting into gold bullion.

This process allows direct contact between activated carbon and leach slurry, enhancing gold recovery rates up to 95–98%.

Table of Contents

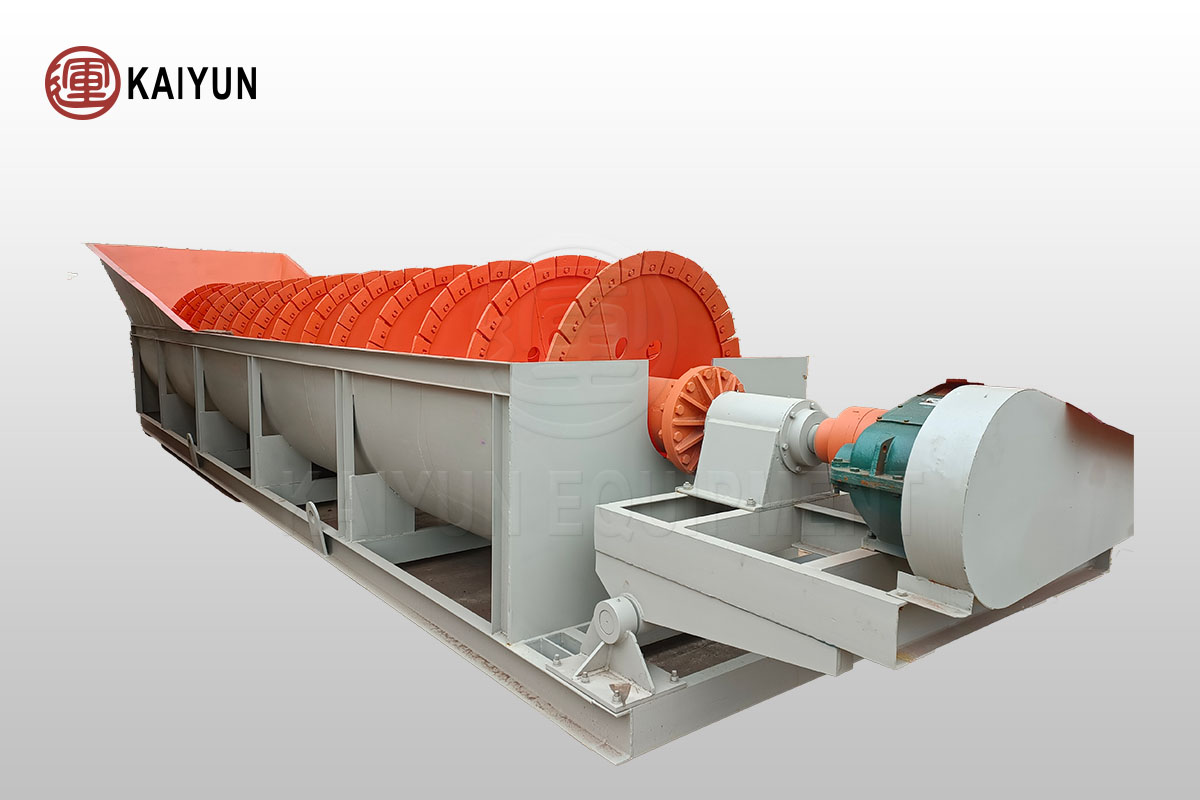

Main Equipment in a CIP Plant

| Equipment | Function |

| Jaw Crusher / Cone Crusher | Primary and secondary crushing |

| Ball Mill / Grinding Mill | Grinding to achieve target particle size |

| Thickener | Slurry concentration before leaching |

| Leaching Tanks | Cyanide leaching of gold-bearing slurry |

| CIP Tanks | Carbon slurry adsorption stage |

| Desorption & Electrolysis System | Gold separation from carbon |

| Smelting Furnace | Producing gold ingots |

📌 Optional units include vibrating screens, slurry pumps, chemical dosing systems, and water treatment modules.

Application Fields

Suitable for low-grade oxide or sulfide gold ores.

Applicable to medium and large-scale gold mining operations.

Ideal for regions with tight environmental standards.

Our Gold CIP process systems are currently operating in countries including Ghana, Tanzania, Sudan, Zimbabwe, Nigeria, and Indonesia.

Key Advantages of Our CIP Plant

High Recovery Rate

95–98% gold recovery efficiency.

Low Operational Cost

Less reagent consumption and carbon loss.

Modular Design

Easy installation and expansion.

Environmental Compliance

Tailings detoxification and water recycling systems.

Turnkey Solutions

From ore testing to plant commissioning.

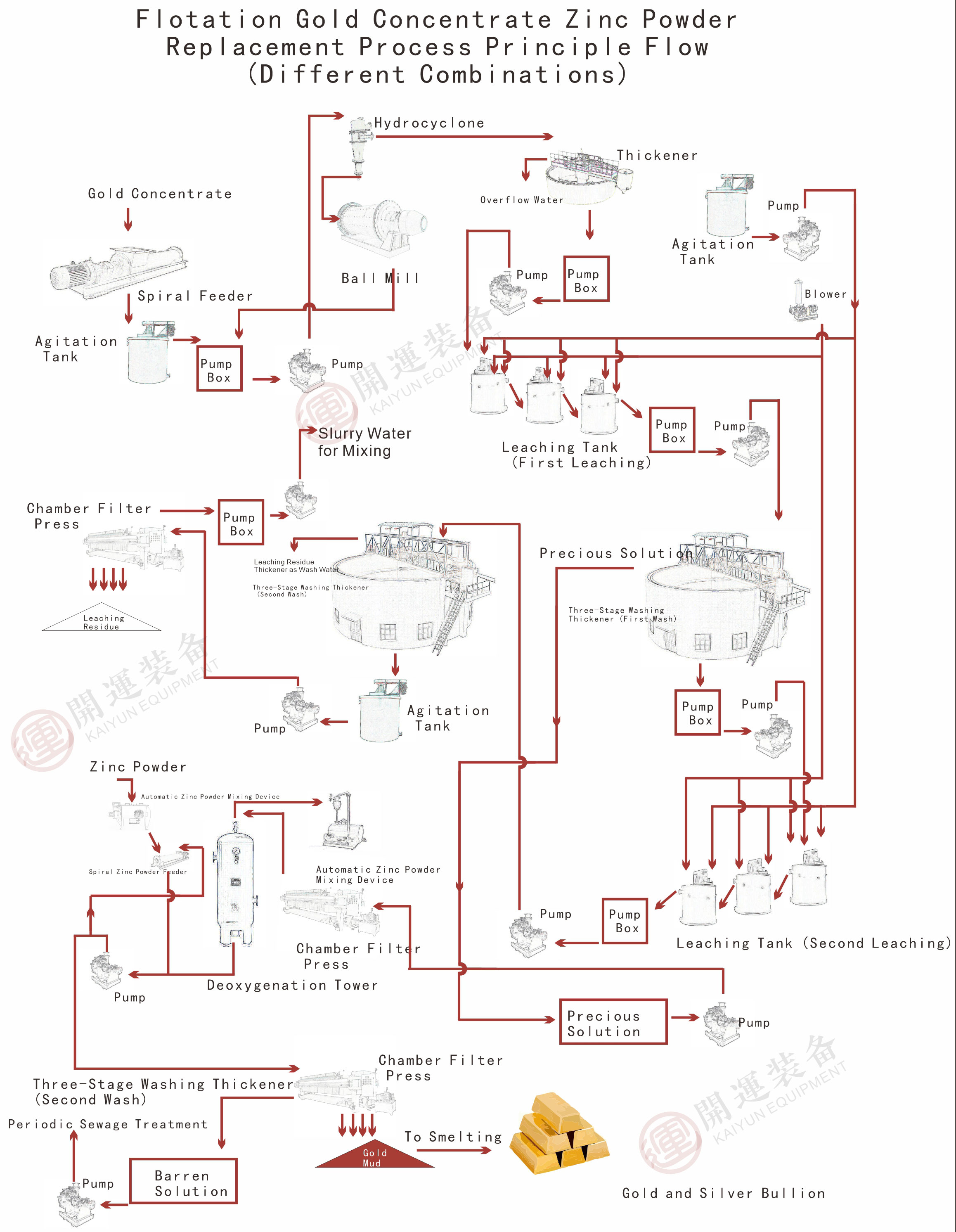

Process flow chart

Why Choose Us?

20+ years of experience in gold extraction technologies.

Professional engineering team for site design and equipment selection.

Overseas installation, training, and technical support available.

OEM/ODM and custom plant layout supported.

📞 Contact us now to get a free flowchart and quotation based on your gold ore sample!