Introduction

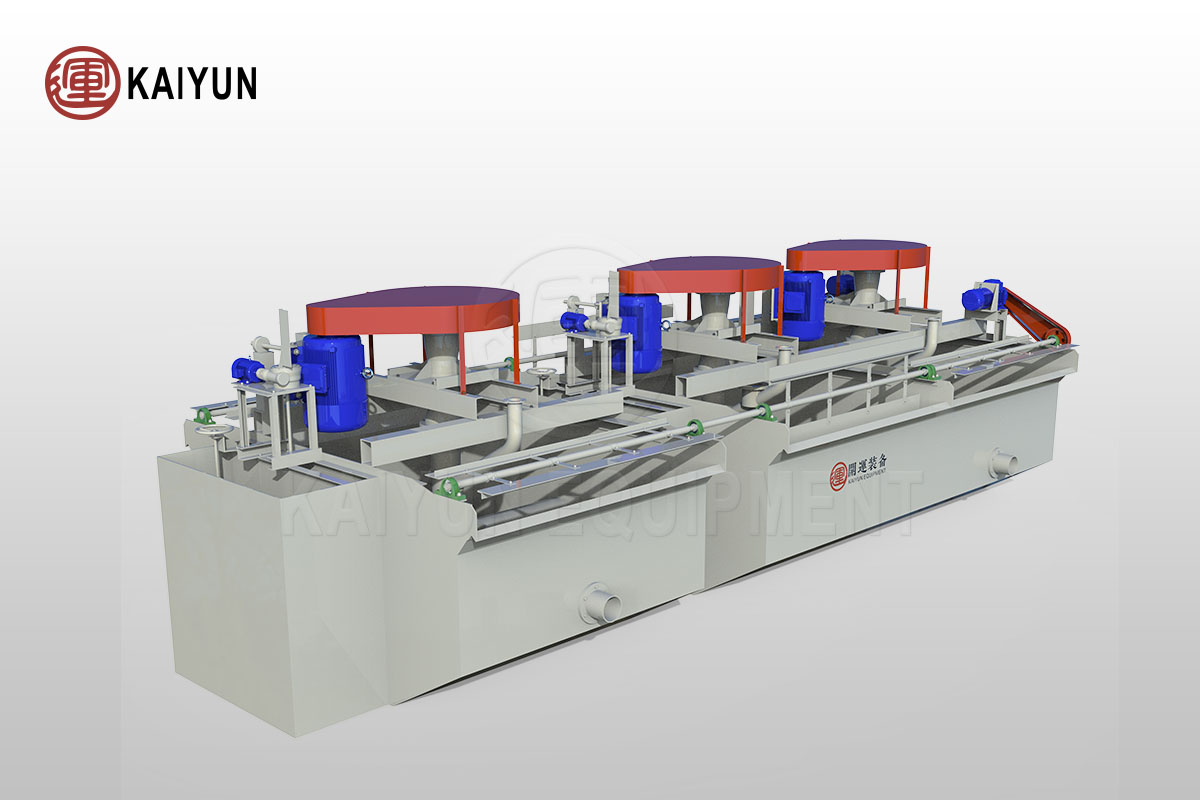

Flotation is a common beneficiation method for gold beneficiation plants to treat rock gold ores. It is often used to treat sulfide mineral gold ores with high floatability. The flotation process can enrich gold in sulfide minerals to a greater extent, and the tailings can be directly discarded. The beneficiation cost is low. 80% of rock gold mines in my country are selected by this process.

Application Field

Gold flotation process is suitable for treating gold-containing sulfide ores with fine gold particles and good floatability. During the flotation process, sulfide ores are enriched in sulfide concentrates as carriers of gold. Flotation can also be used to treat polymetallic gold-containing sulfide ores and carbonaceous ores.

Table of Contents

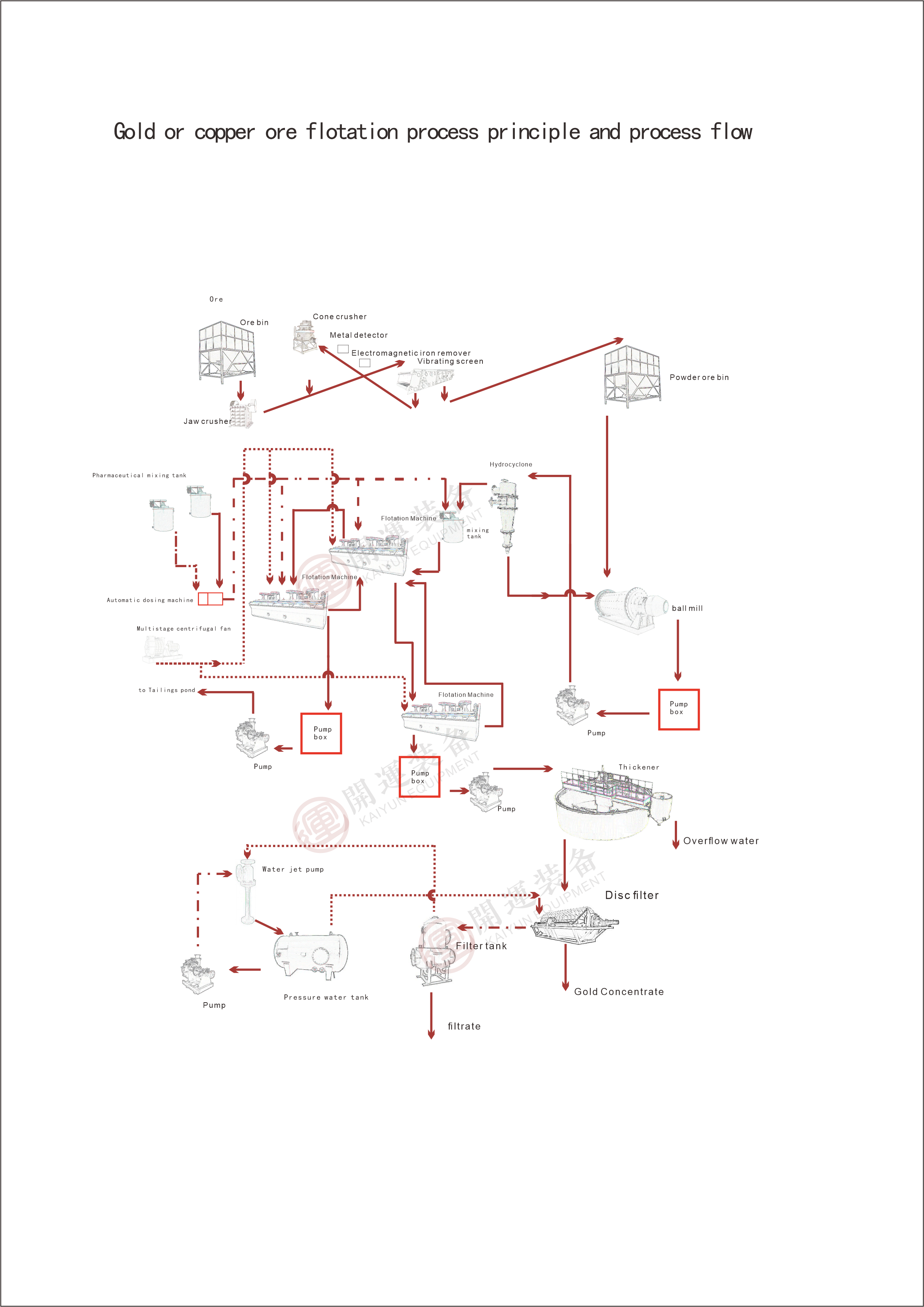

Process Flow

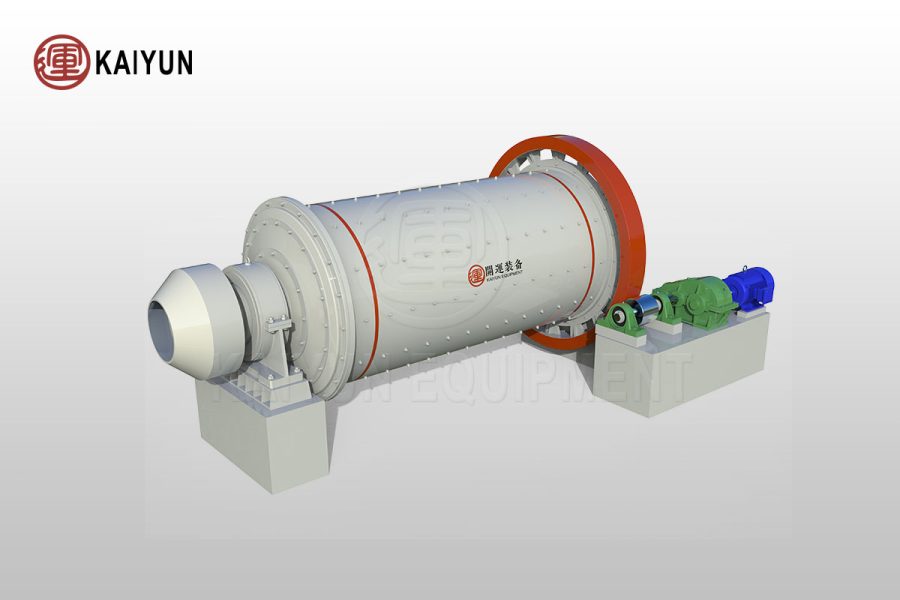

The flotation of gold minerals generally adopts a one-stage grinding-flotation process. For ores with uneven particle size, a stage grinding and flotation process can be used to achieve the enrichment of useful minerals.

Grinding fineness requirements for gold mines

Gold mine grinding fineness requirements, generally speaking, for gold encapsulated in sulfide minerals, only the sulfide ore monomer dissociation is required, but for gold associated with gangue, the grinding fineness needs to reach the gold monomer dissociation. At the same time, the grinding fineness of a certain mineral is determined by experiments.

Gold mine flotation pulp concentration requirements

The principle of gold mine flotation is: flotation of high density and coarse particle size minerals often uses a thicker pulp; on the contrary, when flotation of low density, fine particle size and slime, a thinner pulp is used. The use of a thicker pulp for rough selection can ensure a higher recovery rate, and a thinner concentration for fine selection is conducive to improving the quality of the concentrate.

Other process conditions

In addition to grinding fineness, the process conditions that affect gold flotation also include pulp concentration, flotation reagent dosage, aeration volume, flotation time, etc., which all need to be determined by experiments. In general, the flotation agents used in the flotation process of gold ore include: collector, activator, frother, etc. The collector is used to promote the floating of gold, the activator is to increase the floating speed of gold ore, and the frother is to increase the number of flotation bubbles.

Process Flow Chart