Introduction

Crystalline graphite has natural floatability, and flotation is mainly used to select graphite ore. Flake graphite has good floatability, so flotation is mostly used for separation. For graphite ores with various gangues, gravity separation and flotation combined process can also be used.

Application Field

The graphite ore dressing process is mainly applicable to various graphite ores with different crystal forms and graphite ores with silicate minerals such as mica or pyrite.

Table of Contents

Process Introduction

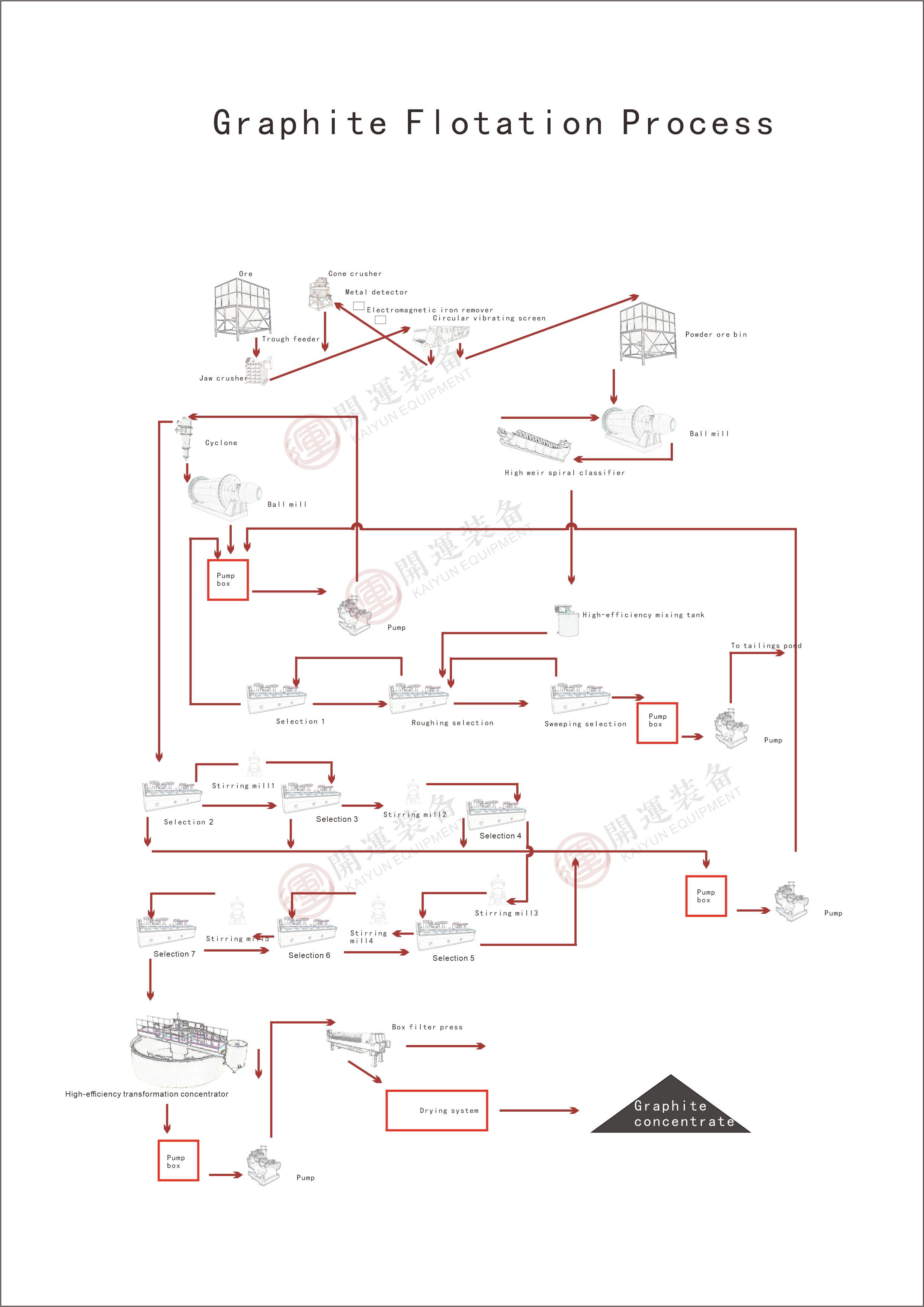

Multi-stage grinding and multi-stage flotation

In order to protect graphite flakes from damage, multi-stage grinding and selection process is often used. After multiple re-grinding and re-selection, the concentrate quality meets the requirements.

Combined process of gravity separation and flotation

For graphite ore with heavy minerals, gravity separation and flotation combined process can be used for selection, that is, first use gravity separation to separate the heavy minerals, and then use flotation to treat the gravity separation tailings (light minerals).

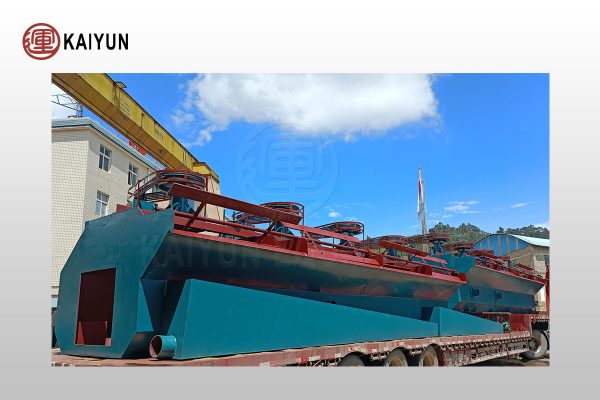

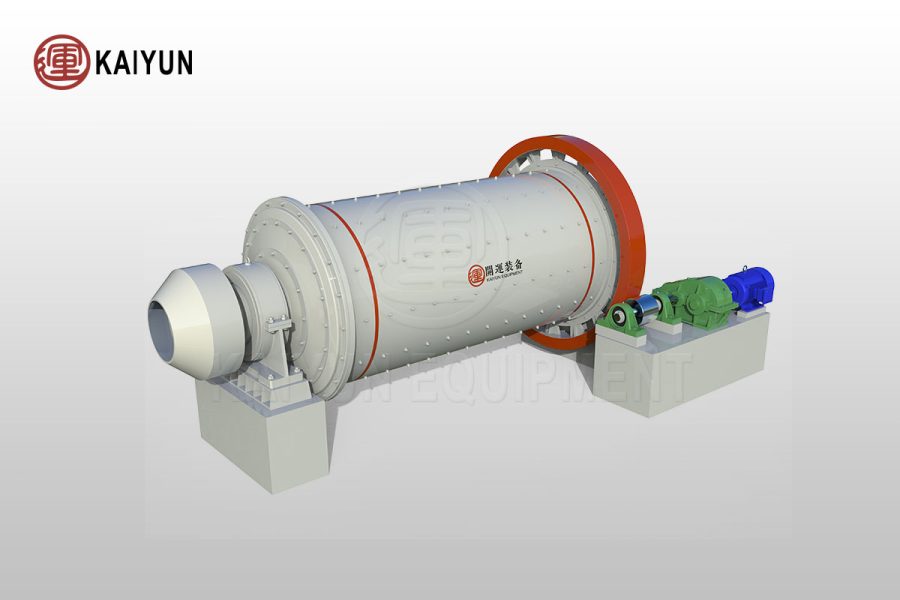

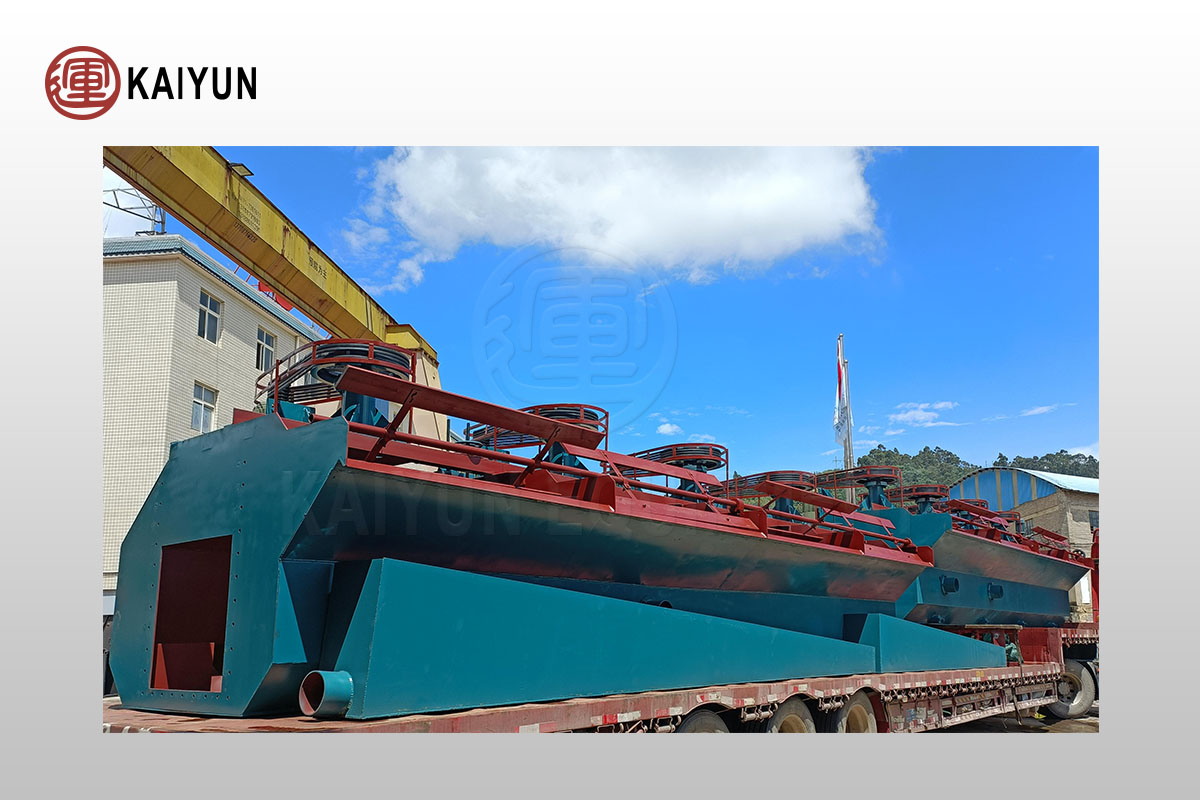

Graphite ore dressing equipment

Generally, jaw crushers are used for coarse crushing of crystalline and amorphous graphite ores, and cone crushers or hammer crushers are used for medium and fine crushing; wet ball mills and grate ball mills are used for grinding; JJF, XCF, and XJB flotation machines are commonly used for graphite flotation; hydrocyclones or belt filters are commonly used for graphite ore dressing and dehydration.

Flotation reagents

In the multi-stage flotation process, commonly used frothers are No. 2 oil, No. 4 oil, ether alcohol, butyl ether oil, etc.; collectors are kerosene, diesel, heavy oil, sulfonate esters, sulfates, phenols, carboxylic acids, etc.

Process Flow Chart