Introduction

As an important raw material in the metallurgical industry, manganese ore is widely used in steel, chemical industry, battery and other fields. In order to extract high-purity manganese elements from low-grade manganese ore, magnetic separation and dressing process has become one of the key technologies.

In the manganese ore dressing process, Kaiyun Intelligent Equipment mainly adopts magnetic separation process, which is divided into two stages: strong magnetic roughing and medium magnetic concentration, which effectively separates useful minerals in manganese ore and improves the grade and utilization rate of ore.

Table of Contents

Application Field

The magnetic separation process of manganese ore is suitable for selecting high-phosphorus, high-silicon and low-iron manganese ore.

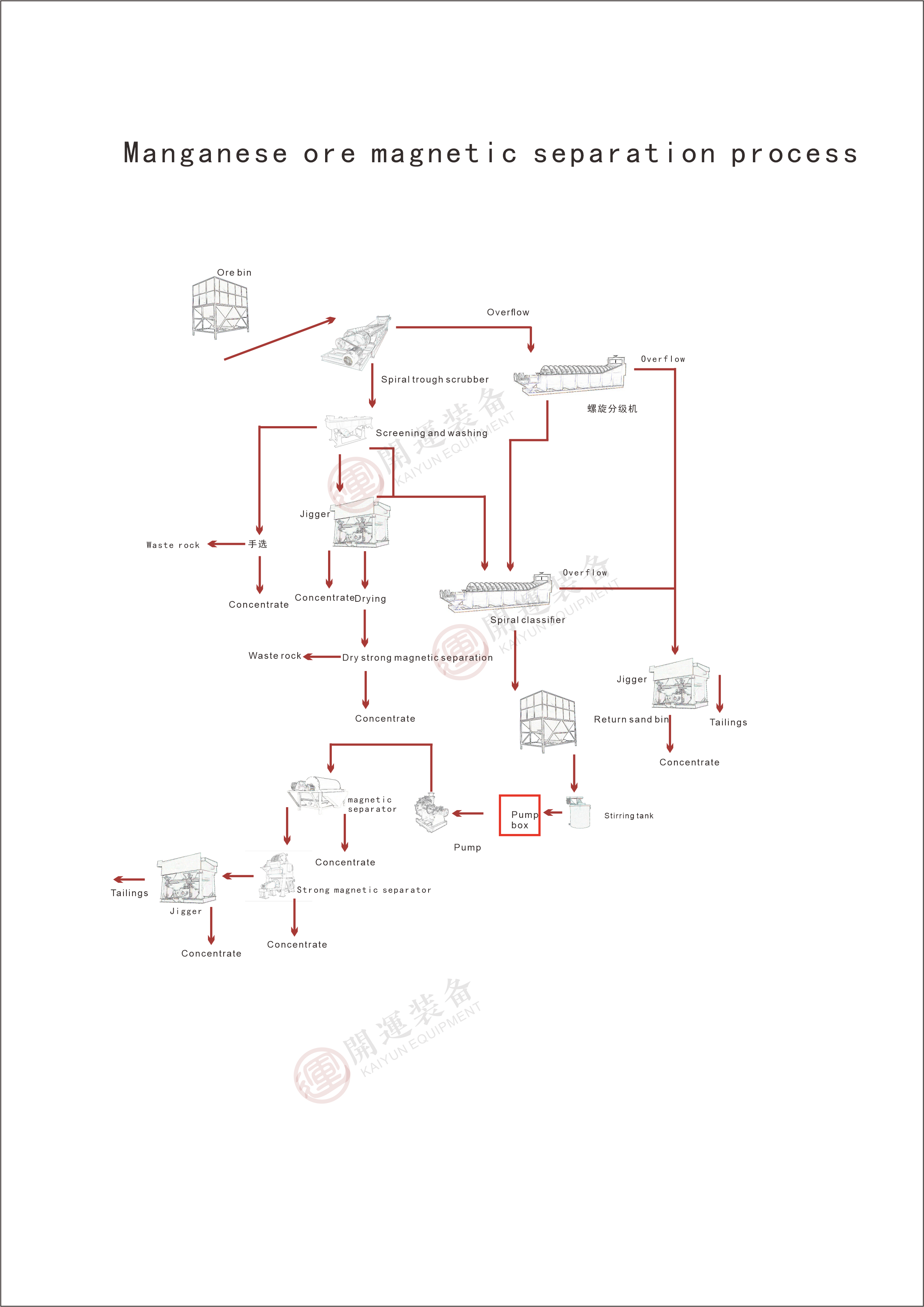

Process Flow

Strong magnetic roughing

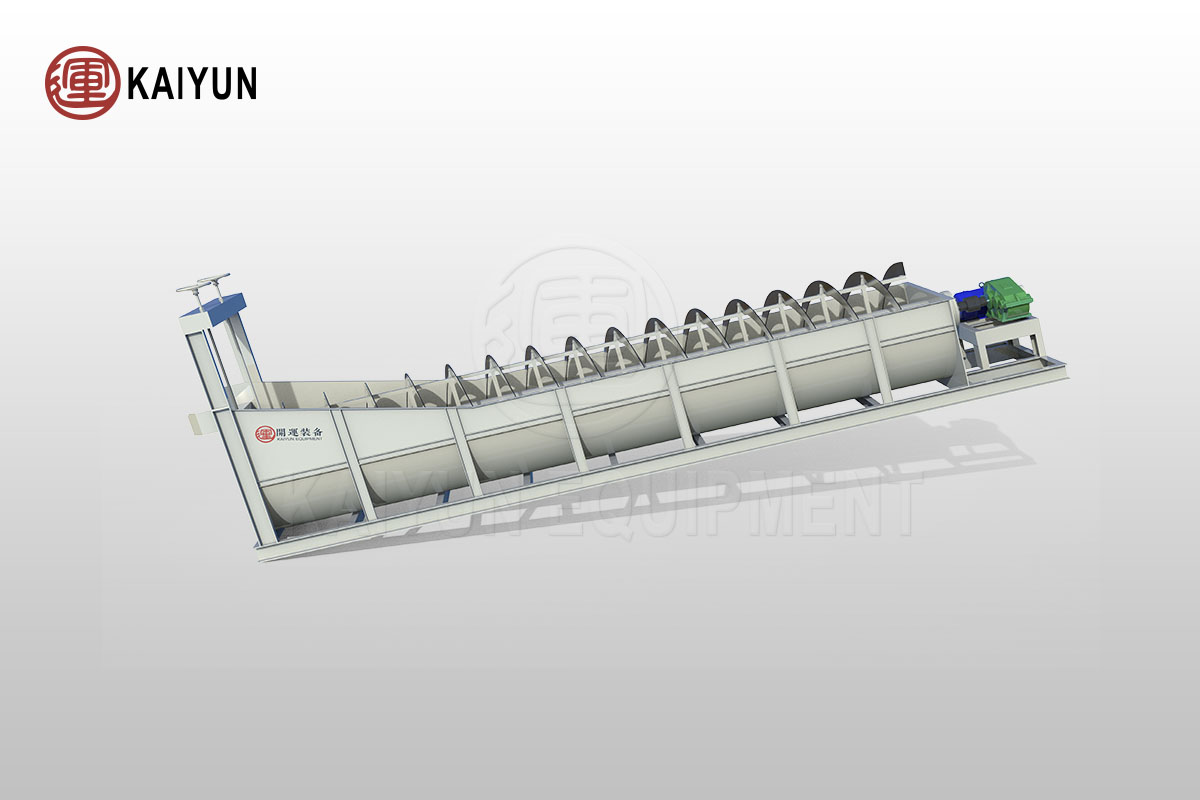

First, a special strong magnetic separator for manganese ore is used to preliminarily remove impurities in manganese ore, and the roughing concentrate is graded by a spiral classifier, and the roughing tailings are directly discharged to the tailings thickener.

Grading

The classification bottom flow of the classifier is sent to the magnetic separator for selection, and the classification overflow is concentrated by a thickener.

Medium magnetic concentration

The medium magnetic concentration tailings are discharged to the tailings thickener, and the medium magnetic concentrate merges with the concentrated bottom flow.

Concentration

The overflow from the concentration enters the return water system, and the bottom flow of the concentration merges with the selected concentrate to become the final selected concentrate.

Process Flow Chart