Introduction

Nickel ore is mainly divided into copper-nickel sulfide ore and nickel oxide ore. Flotation is often used for nickel sulfide ore, while magnetic separation and gravity separation are usually auxiliary beneficiation methods.

The core of nickel ore beneficiation technology is to select the appropriate process flow according to the ore type, grade and final product requirements to maximize resource utilization and reduce production costs.

Application Field

The nickel ore beneficiation process can be applied to copper-nickel ore or nickel oxide ore accompanied by pyrite and other gangue.

Table of Contents

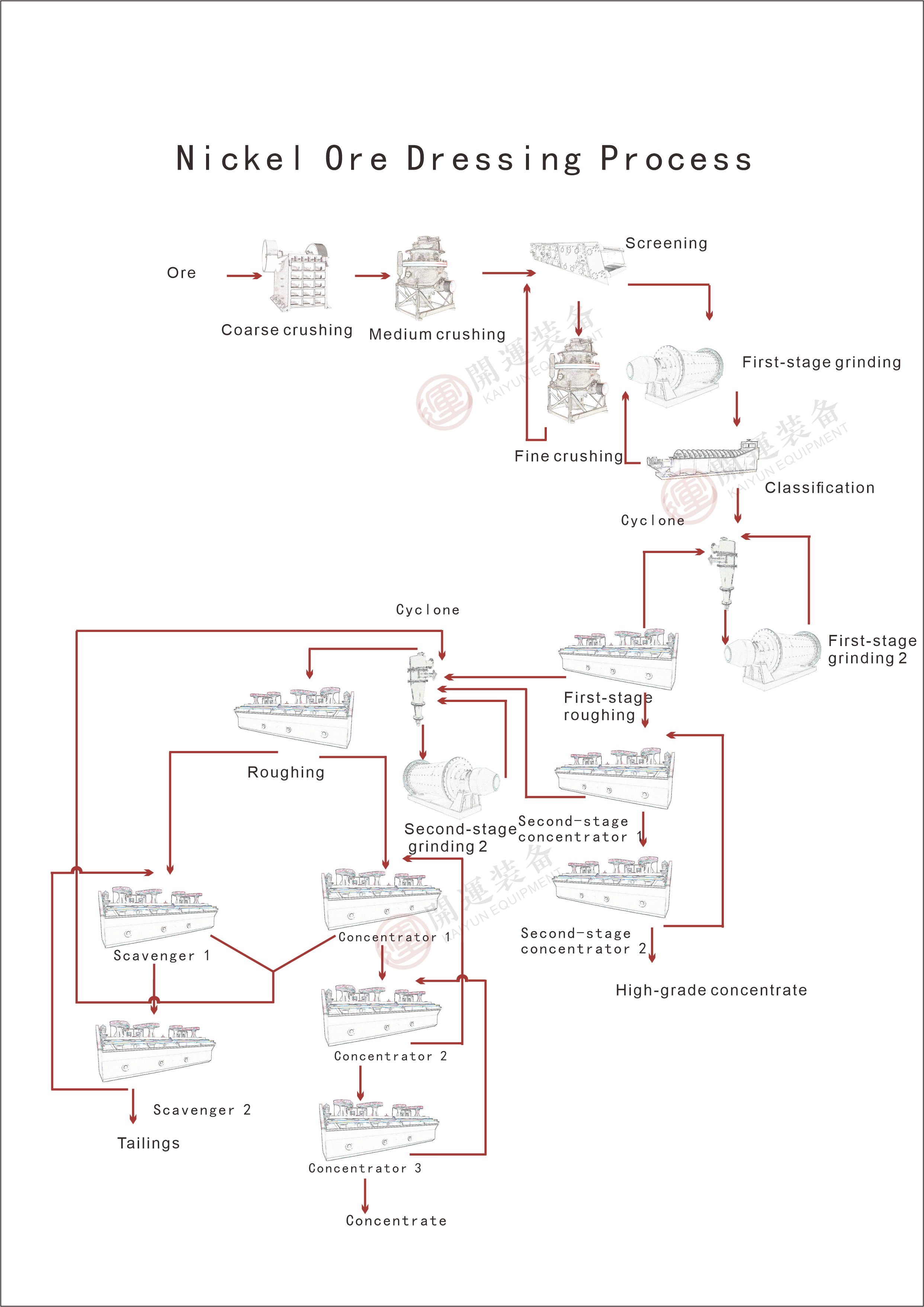

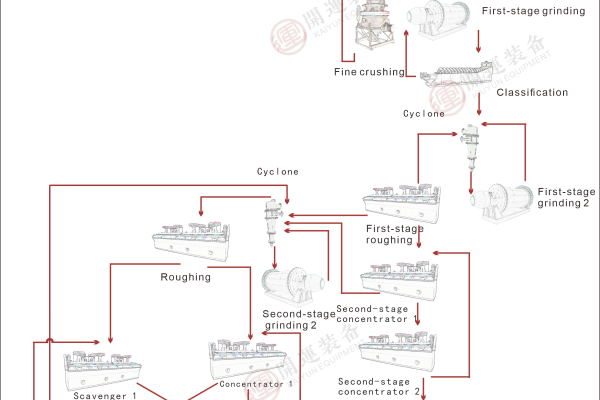

Process Flow

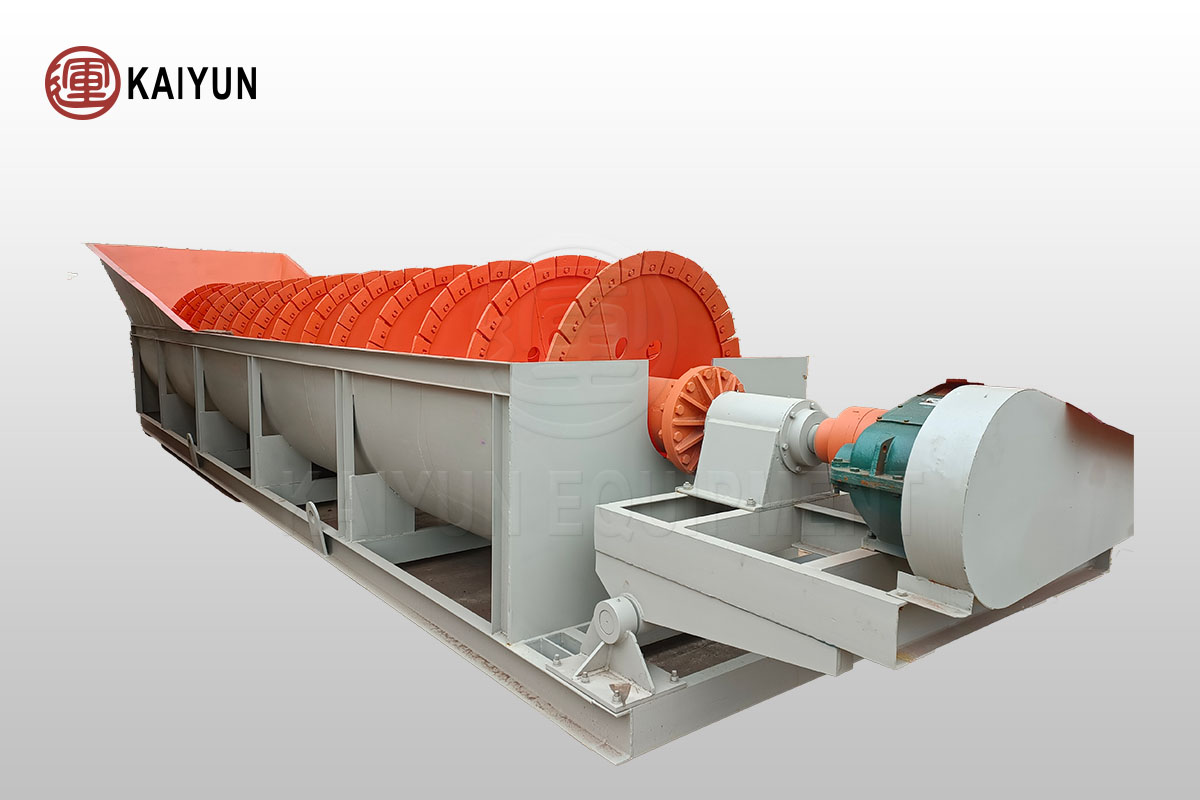

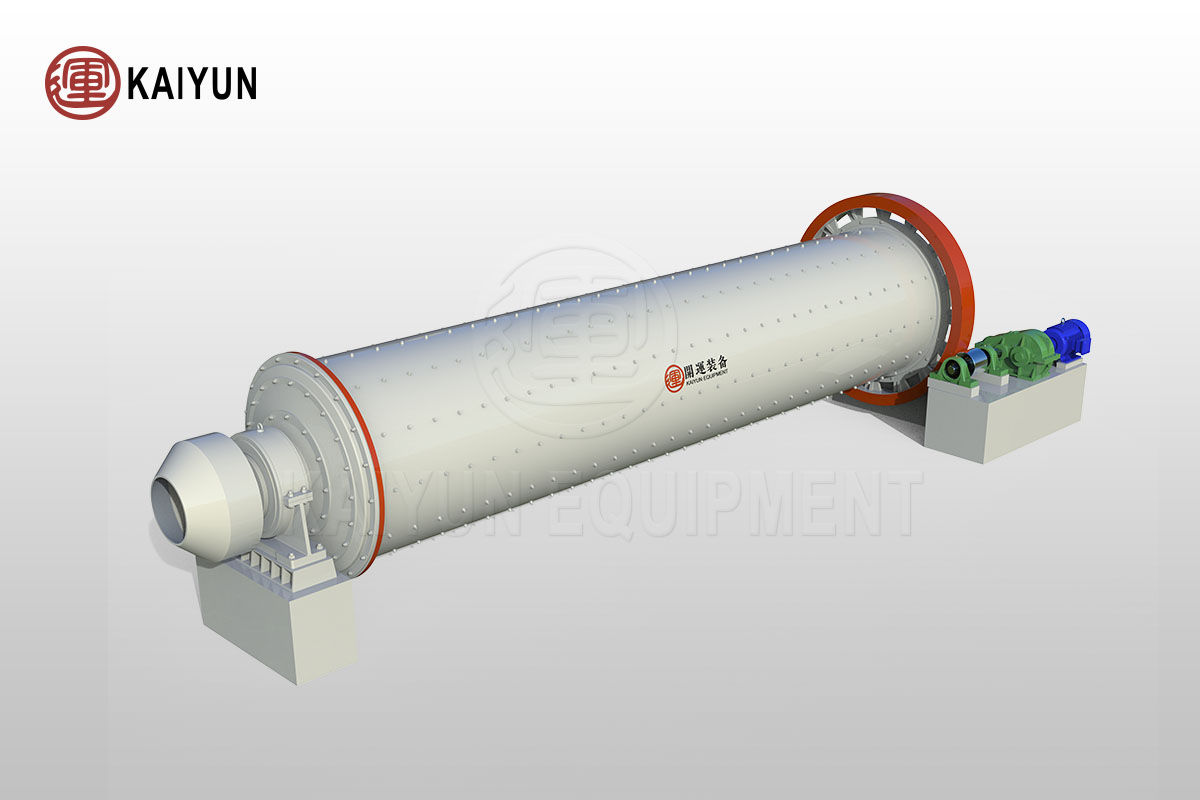

Crushing and Grinding

The crushing and grinding of nickel sulfide ore are usually divided into three stages and one closed-loop process. The ore is first crushed to a suitable particle size, and then enters the ball mill for grinding to ensure the full dissociation of mineral particles.

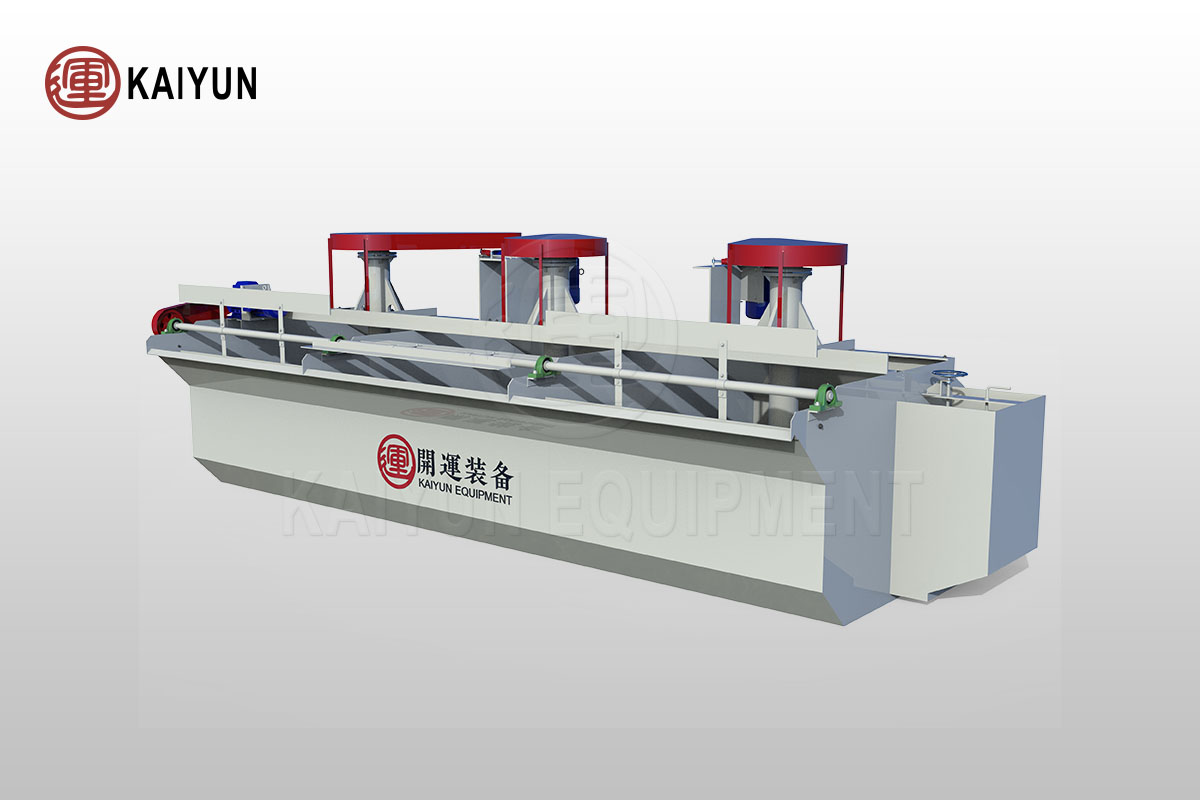

Floatation

The flotation method of nickel sulfide ore is to separate nickel-containing minerals from gangue minerals by adding an appropriate amount of flotation reagent to the slurry. The nickel minerals float up and are recovered under the action of bubbles. Typical flotation process steps include:

1, Roughing: preliminary separation of nickel minerals.

2, Concentration: further improve the concentrate grade.

3, Scavenging: recover tailings in the flotation process to reduce nickel loss.

Dehydration and concentrate treatment

The nickel concentrate obtained after flotation is concentrated and filtered to dehydrate, and finally a high-grade nickel concentrate is obtained.

Factors affecting the selection of nickel ore dressing process

The nature of the ore: different types of nickel ores require different dressing processes. For example, sulfide nickel ore is suitable for flotation, while oxide nickel ore is more suitable for hydrometallurgy or pyrometallurgy.

The grade of nickel ore: The nickel content in the ore also affects the choice of process. High-grade ore can be directly smelted, while low-grade ore may need to be first beneficiated to improve the grade.

Economic and environmental protection: The choice of dressing process also depends on factors such as investment cost, operating cost and environmental impact.

Process Flow Chart