Introduction

The selection of phosphate ore dressing process is mainly based on the type and properties of phosphate ore. Phosphate ore is mainly divided into apatite type, colloidal phosphorite type and sedimentary phosphate ore type. Among them, sedimentary phosphate ore is the most common.

Usually, flotation, gravity separation, scrubbing and desludging methods are used to improve the grade of phosphate ore. Among them, flotation is the most widely used phosphate ore dressing process.

Table of Contents

Application Field

The phosphate ore flotation equipment production line can be applied to phosphate ore with complex and diverse ore structure, complex mineral occurrence relationship, small particle size, close mosaic relationship, common mixed symbiosis, and difficult monomer dissociation.

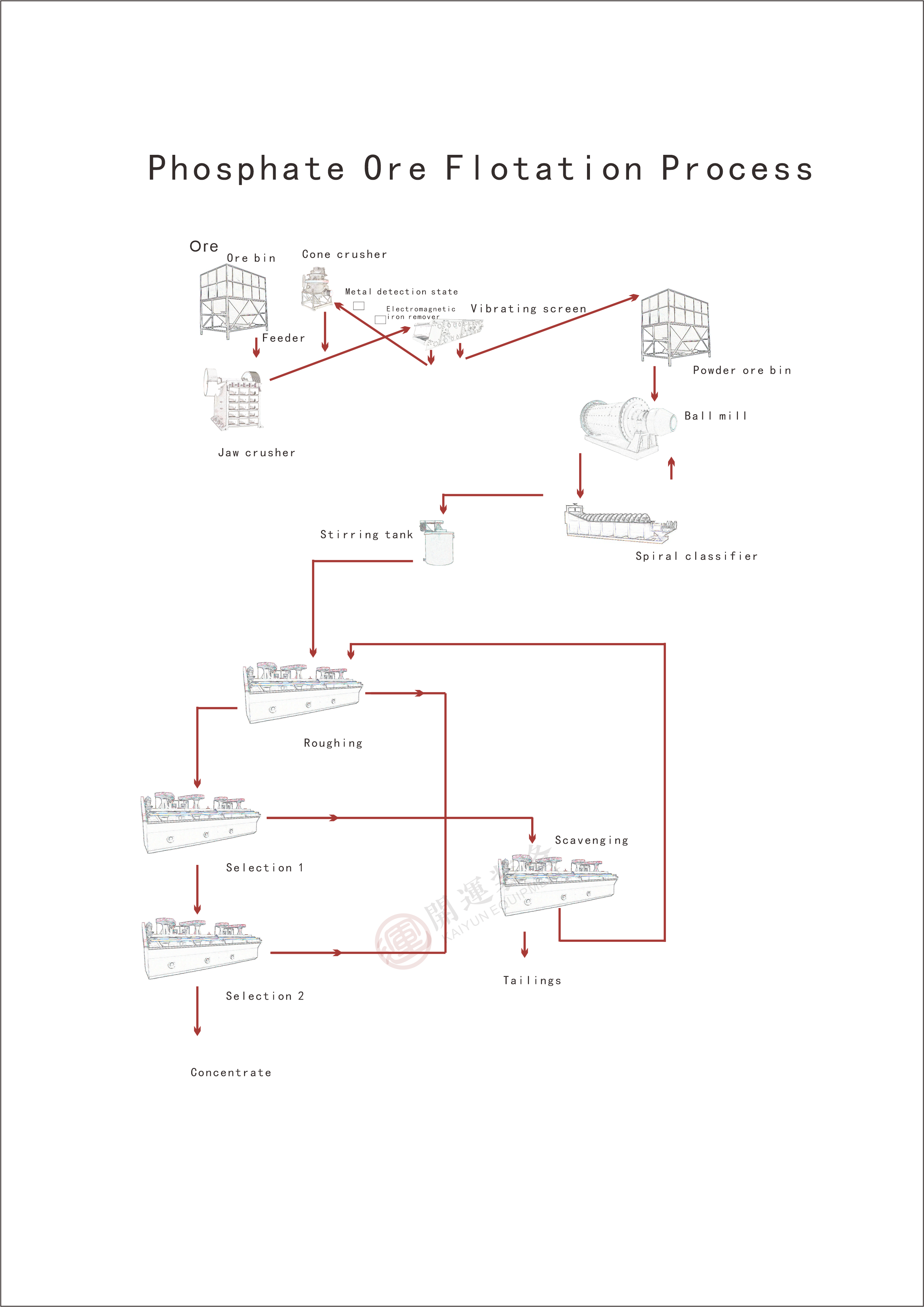

Process Flow

The flotation method separates phosphate minerals from gangue minerals by changing the floatability of the mineral surface.

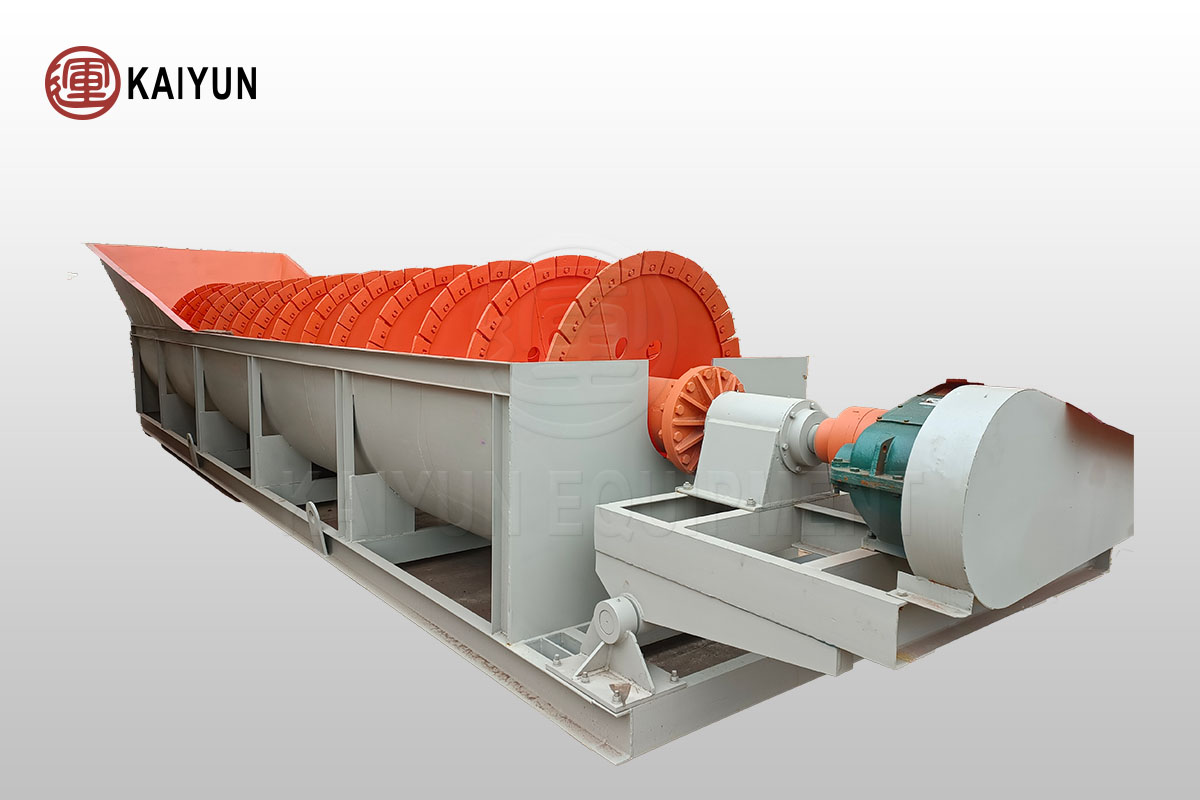

Crushing and Grinding

First, the phosphate ore is crushed and ground to ensure that the mineral particles reach a suitable flotation particle size.

Slurry adjustment and reagent addition

Add reagents (such as collectors, frothers, etc.) to the flotation tank, and enrich the phosphate minerals in the foam layer through bubbles after slurry adjustment.

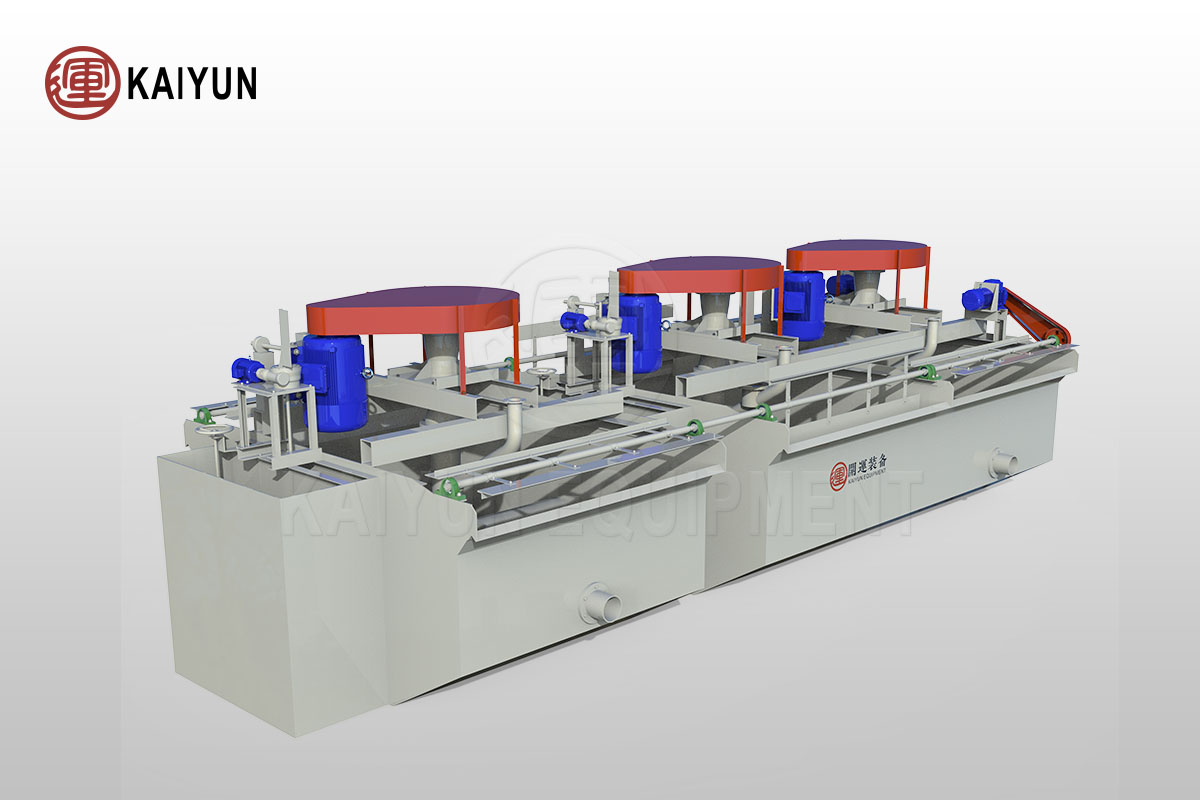

Roughing, concentrating and scavenging

Perform multi-stage flotation operations to improve the grade of phosphate concentrate through roughing, concentrating and scavenging.

Concentration and dehydration

After flotation, the phosphate concentrate is concentrated and dehydrated to finally obtain high-grade phosphate concentrate.

Advantages

Phosphate Ore Dressing Process can effectively process complex ores, especially phosphate ores containing impurities such as silicon, iron, and aluminum.

Phosphate Ore Dressing Process is suitable for large-scale processing of low-grade ores.

Process Flow Chart