Introduction

Silver ore flotation process is a widely used beneficiation method in current silver ore dressing plants, that is, various flotation agents are added during the selection process to adjust the physical and chemical properties of the selected minerals and flotation media, expand the difference in hydrophobicity between silver minerals and gangue minerals, and thus achieve the separation of silver minerals from gangue minerals. This method can enrich silver into sulfide mineral concentrates as much as possible, and is conducive to the comprehensive recovery of silver mineral resources.

Table of Contents

Application Fields

Silver ore beneficiation technology is mainly used to recover silver and associated metal minerals. Silver-containing ores are mainly divided into two categories: silver-gold ores and lead-zinc-copper associated ores.

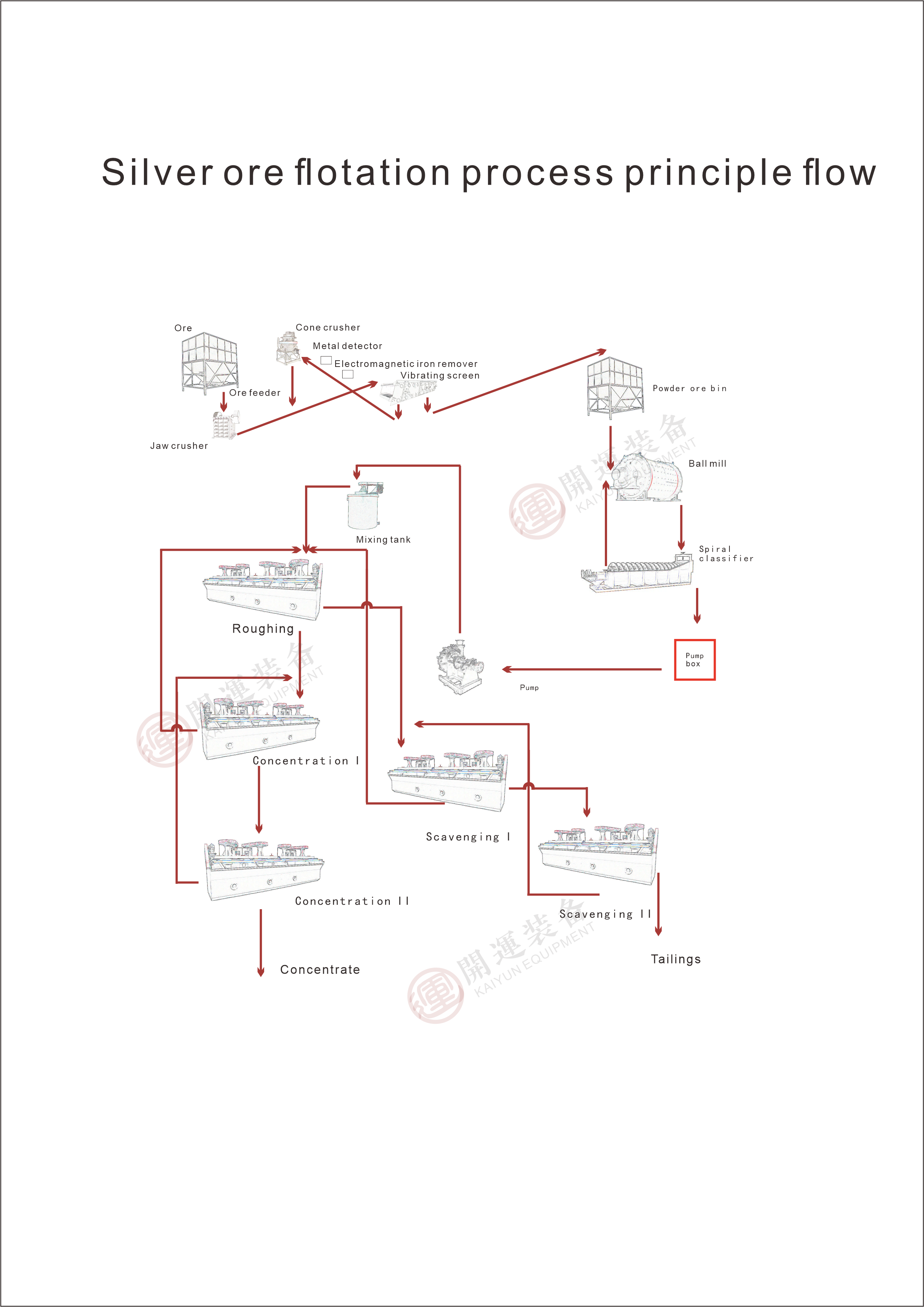

Process Flow

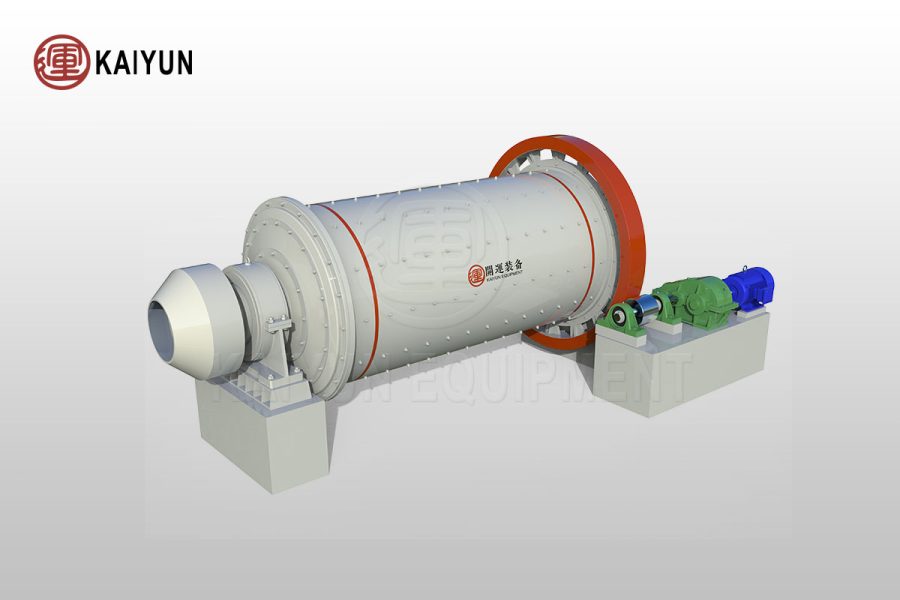

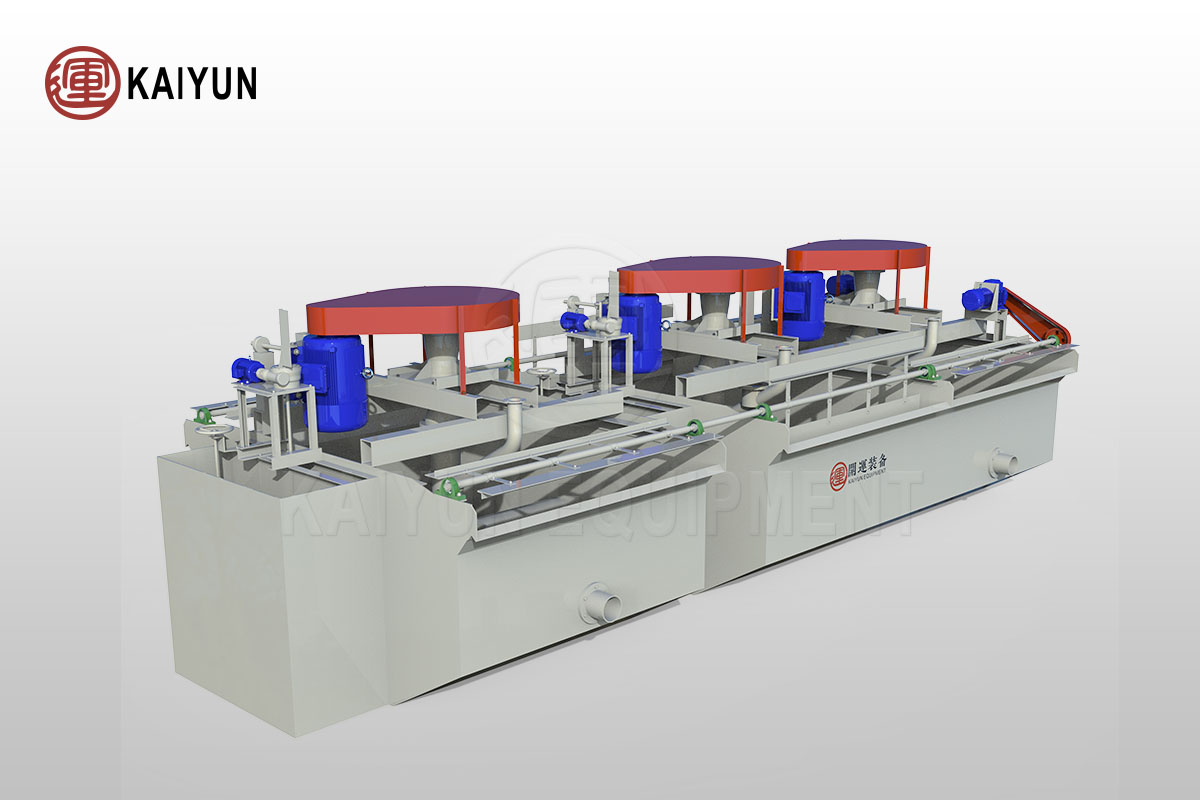

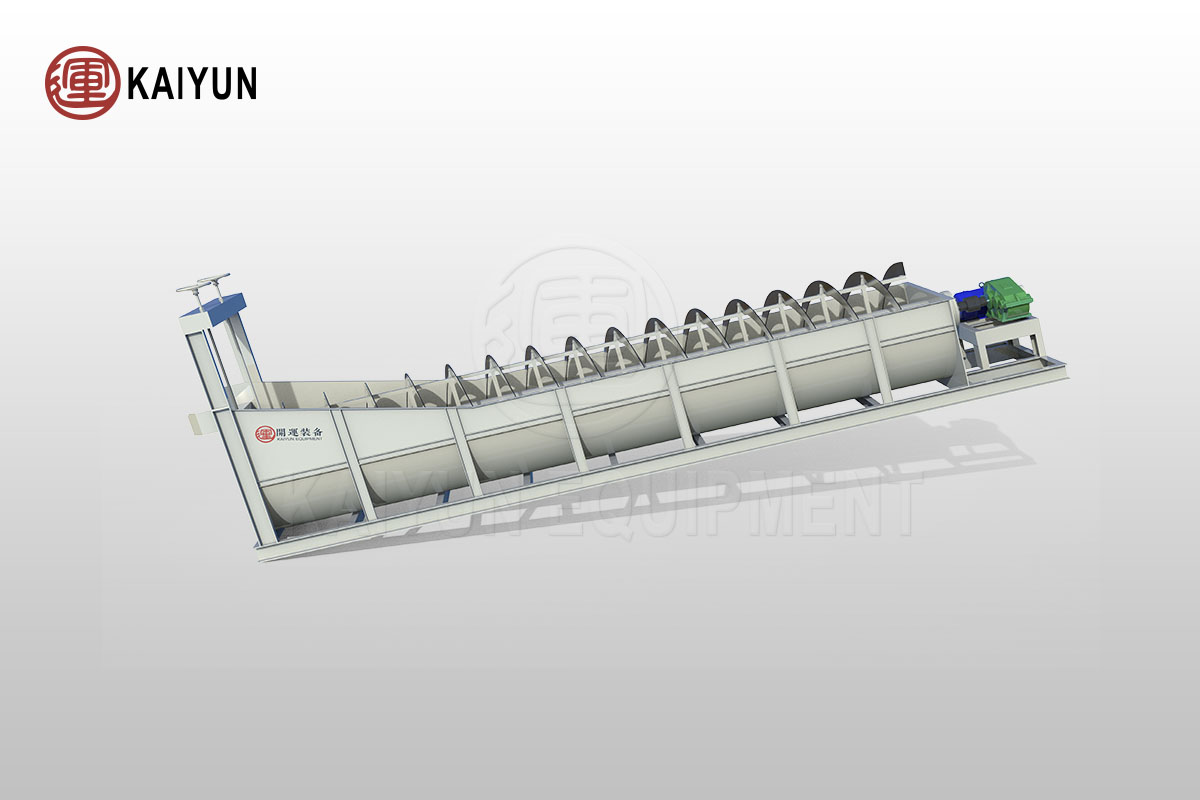

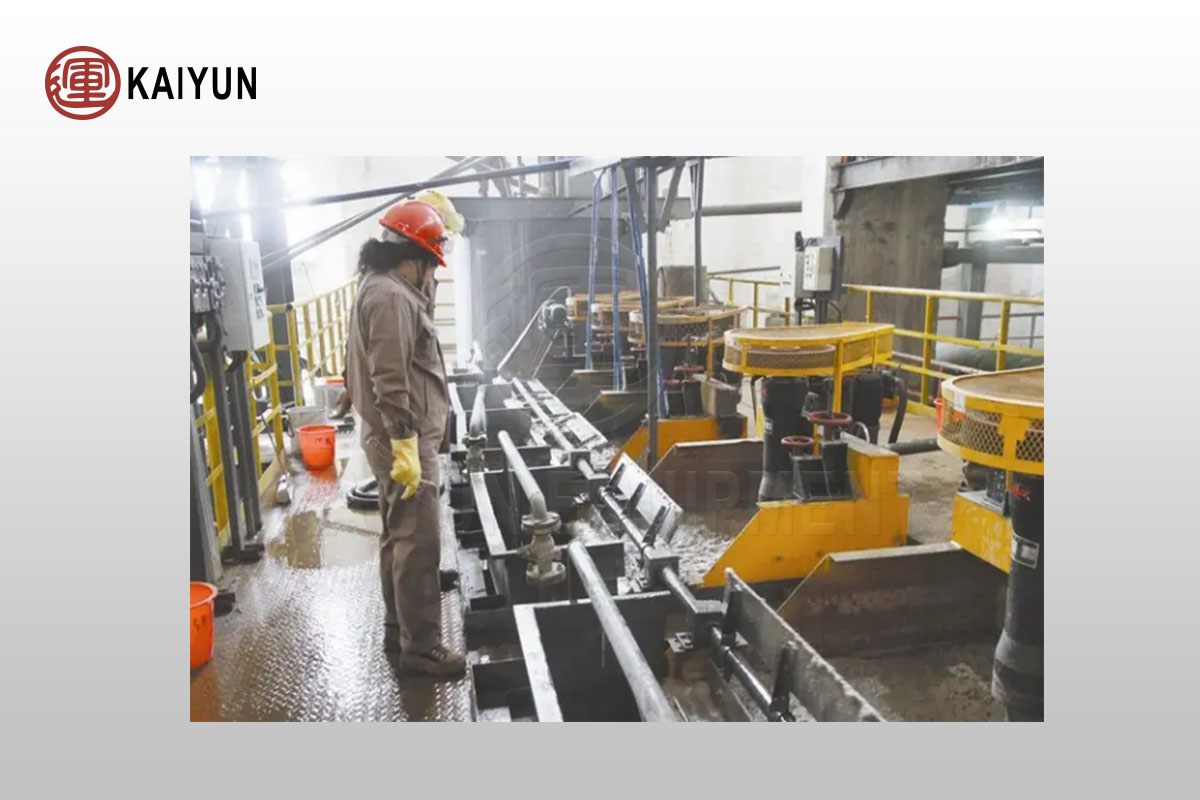

Silver ore flotation production line is mainly composed of flotation machine, leaching stirring tank, zinc powder replacement device, two-layer (three-layer) washing and thickening machine, etc. This production line has the advantages of high efficiency, low energy, high processing capacity and economic rationality.

1. Mixed roughing is carried out under rough grinding, and the obtained rough concentrate is further refined after re-grinding to fully dissociate the silver minerals as much as possible. In order to obtain high-grade and high-recovery concentrate, energy consumption is saved at the same time.

2. In the roughing section, yellow medicine and black medicine are used in combination to enhance the silver capture capacity and reduce multiple cycles and inaction losses; make full use of the secondary enrichment effect of foam, and wash the concentrate foam without adding water to reduce impurities in the foam, so as to achieve the purpose of enhanced flotation.

3. Use stage separation to recover useful minerals of different particle sizes as much as possible and improve concentrate indicators.

Advantages

Silver ore flotation process design is adapted to local conditions and has a reasonable layout.

Silver ore flotation process is advanced and the equipment is reliable.

Silver ore flotation process has low investment cost and high mineral processing index.

Process Flow Chart