Introduction

The soft rock sand and gravel production line is specifically designed for processing relatively softer materials such as limestone, shale, and other sedimentary rocks into sand, gravel, and aggregates. These materials are generally easier to crush and process compared to hard rocks, which allows for a more efficient production process with lower energy consumption.

Applications

Soft rock sand and gravel are commonly used in the construction of buildings, roads, concrete mixing, and other civil engineering projects that require quality aggregates. The material is also widely used in landscaping and in the production of various construction materials such as concrete blocks and asphalt.

Key Components

Feeder: Delivers the raw soft rock materials to the crusher in a uniform flow to optimize crushing efficiency.

Primary Crusher: Usually a jaw crusher or hammer crusher, which breaks down the larger rocks into smaller, manageable sizes.

Secondary Crusher: Can be a cone crusher, impact crusher, or hammer crusher, depending on the desired particle size and shape.

Vibrating Screen: Separates the crushed material into various sizes, ensuring proper grading and sorting for different applications.

Sand Washing System: In some cases, the material is washed to remove dirt, clay, and other impurities to improve the quality of the sand and aggregates.

Stockpiles/Storage: The finished product is stored or transported to construction sites or aggregate markets.

Features

95% of the work is completed in the factory, and the on-site deployment and production are quick, without the need for civil engineering and foundation treatment.

Cost-Effective: Processing soft rocks typically requires less energy compared to hard rocks, which can reduce operational costs.

High Efficiency: Soft rock production lines are capable of producing a large quantity of high-quality sand and gravel with minimal wear and tear on equipment.

Versatile Products: Soft rock production lines can produce a wide range of products, from fine sand to coarser aggregates, suitable for construction, concrete production, and other industrial uses.

Environmental Considerations: These lines can include features like dust control systems and water recycling to reduce environmental impact, though the softer materials generally create less dust compared to harder rocks.

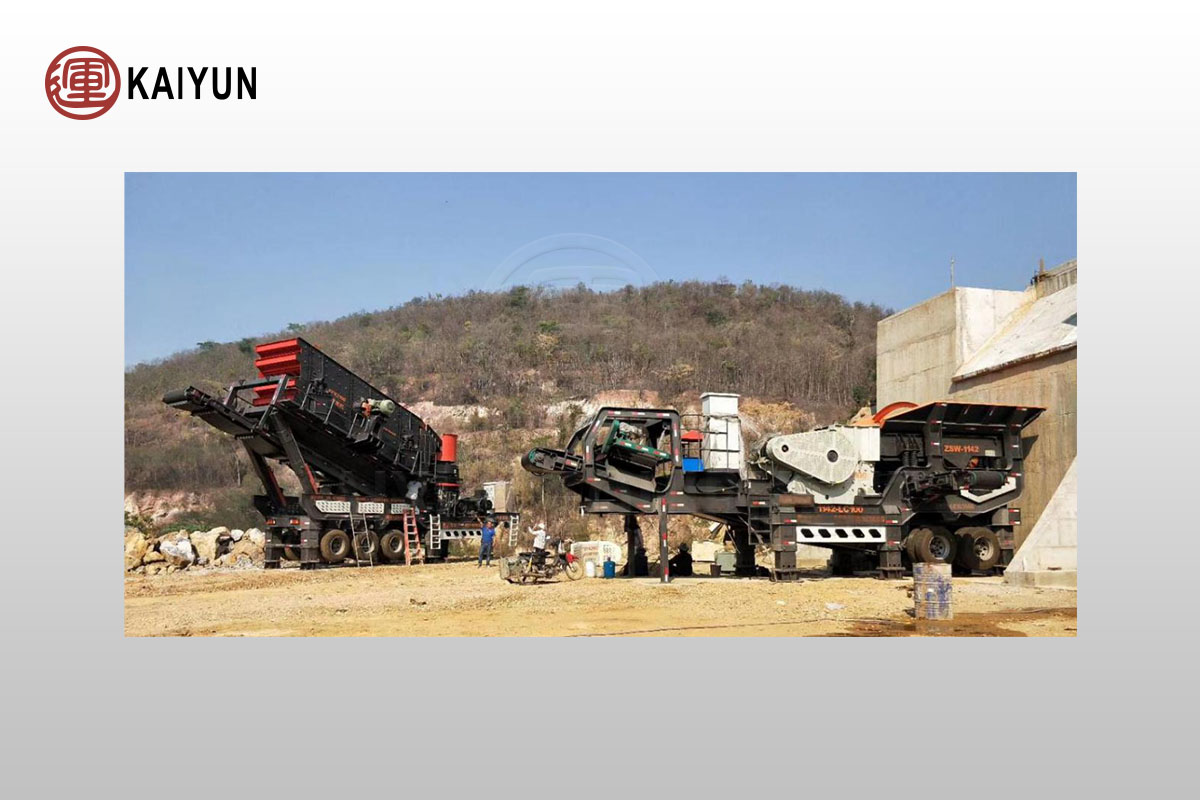

Application Cases

Project background: The group’s 150 tons per hour sand and gravel production line

Raw material: limestone

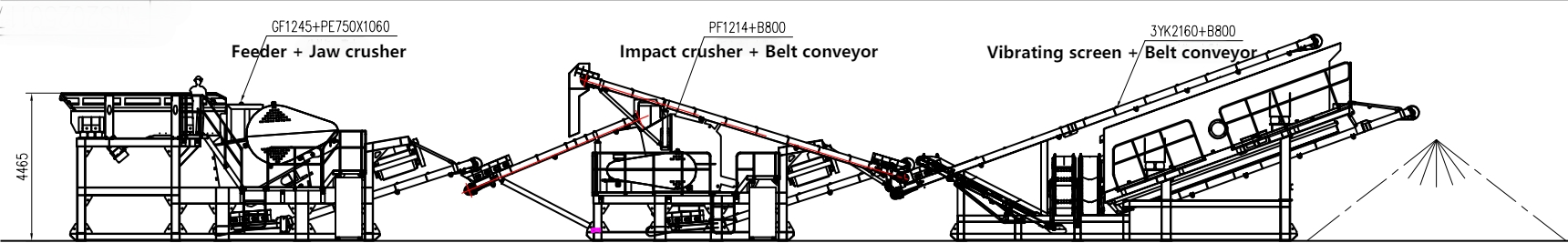

Device Configuration

Jaw crusher module parameters

| No. | Name | Specification Model | Qty | Power(kw) | Remark |

| 1 | Feeder | GF1245 | 1 | 2*7.5 | |

| 2 | Jaw crusher | PE750X1060 | 1 | 110 | |

| 3 | Belt conveyor | B1000X8 | 1 | 7.5 | |

| 4 | Belt conveyor | B500X4 | 1 | 2.2 | |

| 5 | Iron remover | RCYD-10 | 1 | 2.2 | Optional |

Impact crusher module parameters

| No. | Name | Specification Model | Qty | Power(kw) | Remark |

| 1 | Feeding belt conveyor | B1000X7 | 1 | 7.5 | |

| 2 | Impact crusher | PF1214 | 1 | 132 | |

| 3 | Outlet belt conveyor | B1000X8 | 1 | 7.5 | |

| 4 | Return belt conveyor | B650X12 | 1 | 5.5 |

Vibrating screen module parameters

| No. | Name | Specification Model | Qty | Power(kw) | Remark |

| 1 | Vibrating screen | 3YK2160 | 1 | 30 | |

| 2 | Loading belt conveyor | B1000X12.5 | 1 | 11 | |

| 3 | Under-screen belt conveyor | B1000X8 | 1 | 7.5 | |

| 4 | Side belt 1 | B500X6 | 2 | 2X4 | |

| 5 | Return belt conveyor | B500X6 | 1 | 4 |