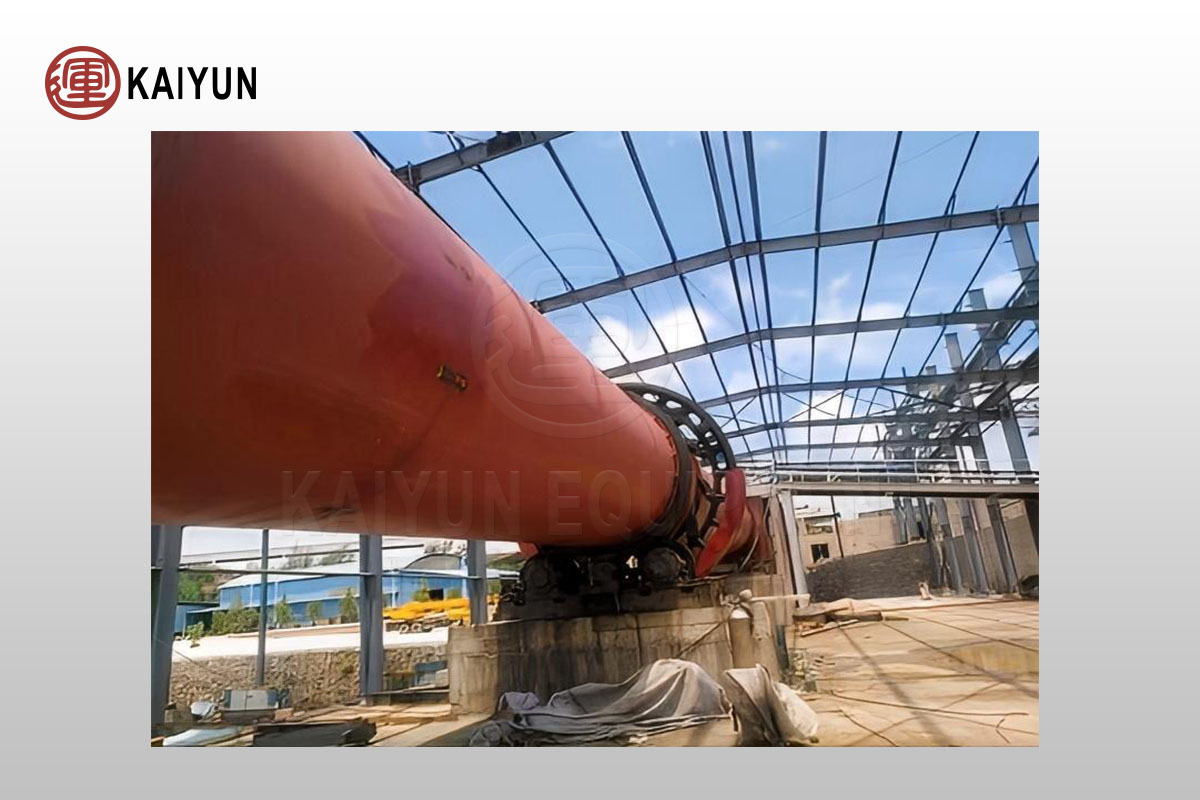

Product Introduction

Aluminum Dross Rotary Kiln is one of the key devices for the treatment and recycling of aluminum dross. It is primarily used for the calcination of aluminum dross, where high-temperature treatment is applied to oxidize aluminum metal, remove harmful impurities, and extract valuable aluminum resources.

Applications of Aluminum Dross Rotary Kiln

The aluminum dross rotary kiln is widely used in aluminum smelting plants, aluminum product processing factories, and other enterprises for the recycling and treatment of aluminum dross. The use of a rotary kiln allows for the effective recovery of aluminum resources, reduces waste and environmental pollution, and has significant economic and environmental benefits.

Table of Contents

Structural Features of Aluminum Dross Rotary Kiln

Kiln Body

Made of welded steel plates and lined with refractory materials to resist high temperatures and corrosion.

Transmission System

Includes the main motor, reducer, and transmission device, which drive the rotation of the kiln.

Support Devices

Consists of riding rings, support rollers, and guide rollers, which support and stabilize the kiln body.

Sealing Device

Utilizes special sealing structures to prevent heat and material leakage, ensuring the stability of kiln pressure and temperature.

Feeding and Discharging Devices

Designed with efficient feeding and discharging systems to ensure continuous material flow and avoid blockages and material loss.

Advantages of Aluminum Dross Rotary Kiln

High Efficiency and Energy Saving

The rotary kiln has excellent heat exchange efficiency, making full use of fuel heat and reducing energy consumption.

Ease of Operation

The equipment is highly automated, easy to operate, and maintain.

Environmental Compliance

Advanced flue gas treatment technologies are employed to reduce emissions, meeting environmental standards.

Large Processing Capacity

The rotary kiln handles large volumes, suitable for large-scale aluminum dross treatment projects.

Strong Adaptability

With a simple structure, the equipment is adaptable to different compositions and sizes of aluminum dross.

Process Flow of Aluminum Dross Rotary Kiln

The aluminum dross processing technology involves the treatment and recycling of aluminum dross, a by-product generated during aluminum smelting. Aluminum dross contains a certain amount of aluminum metal and alumina, as well as other impurities. The main goal is to recover aluminum metal and alumina, reduce waste volume, and prevent environmental pollution.

Crushing and Screening

Aluminum dross is usually crushed first to reduce particle size, followed by screening to separate materials of different sizes.

Drying

Since aluminum dross typically contains moisture, the drying process removes the moisture and improves the efficiency of subsequent processing.

Calcination

The dried aluminum dross is subjected to high-temperature calcination, generally between 800°C and 1200°C. This step aims to oxidize aluminum metal in the dross to form alumina while volatilizing some harmful impurities.

Cooling and Grinding

The calcined aluminum dross is rapidly cooled to prevent re-oxidation. The cooled dross is then ground to reduce particle size further, increasing surface area and enhancing subsequent processing.

Magnetic and Flotation Separation

Physical separation methods such as magnetic separation and flotation are used to separate aluminum metal and alumina from other impurities. Magnetic separation removes ferromagnetic impurities, while flotation is used to extract aluminum metal and alumina.

Chemical Treatment

Depending on the needs, chemical treatments like acid leaching or alkaline leaching may be used to further purify alumina.

Recovery and Utilization

The processed aluminum metal and alumina can be recycled for producing new aluminum products or used as raw materials for other industries. Residual waste is treated and can be safely disposed of or used in construction materials like bricks.

Technical Parameters

| Model | Output (t/h) | Number of supports | Reducer | Motor | Power (kw) |

| φ2.2x45m | 3.5 | 3 groups | ZS125-5 | YVF₂-225M-4 | 45 |

| φ2.5x50m | 5 | 3 groups | ZS145-5 | YVF₂-250M-4 | 55 |

| φ2.8x50m | 8.5 | 3 groups | ZS165-6 | YVF₂-280S-4 | 75 |

| φ3.0x55m | 11 | 3 groups | ZS165-3 | YVF₂-280M-4 | 90 |

| φ3.2x60m | 15 | 3 groups | ZL130-16 | YVF₂-315L2-6 | 132 |

| φ3.6x64m | 20 | 3 groups | ZSY560-63 | YVF₂-355M1-6 | 160 |

| φ3.8x70m | 26 | 3 groups | ZSY560-63 | YVF₂-355M4-6 | 200 |