Product Introduction

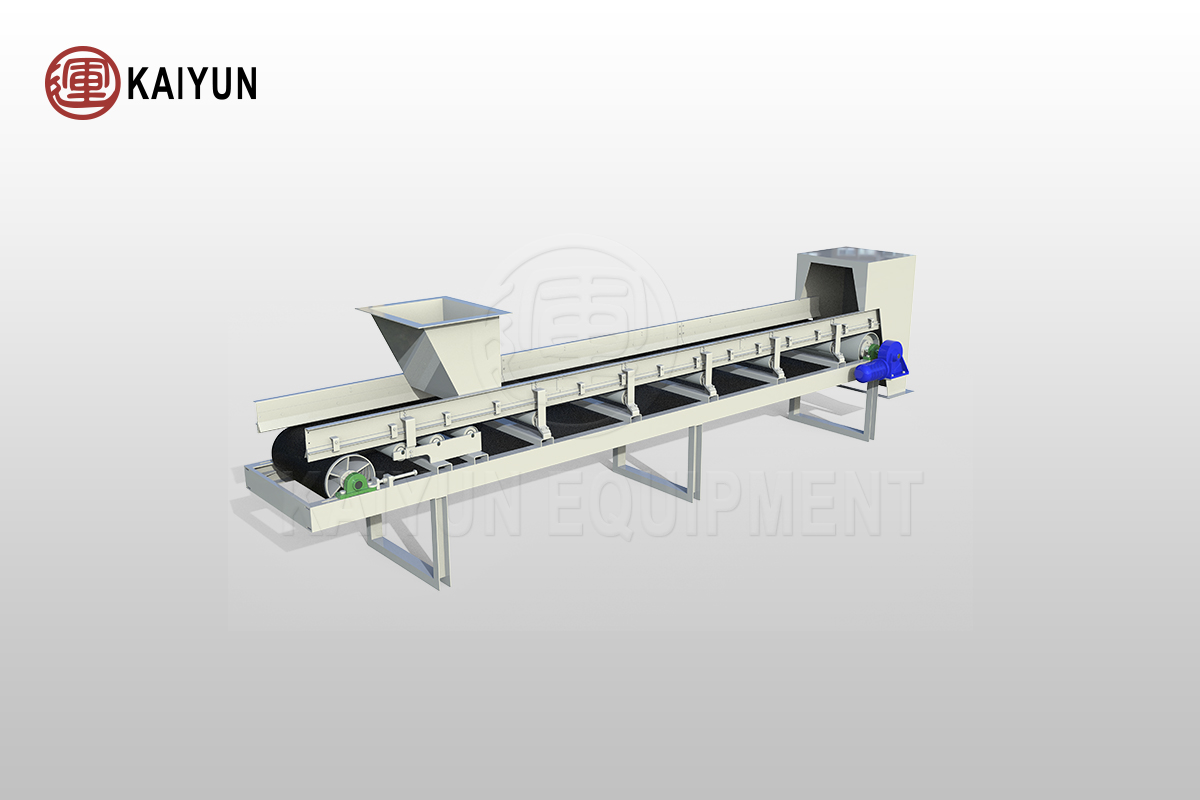

The belt feeder, specifically designed for mining applications, boasts powerful load-bearing capacity and wide material adaptability, making it an indispensable logistics tool in various industries including metallurgy, ore dressing, construction materials, and hydropower.

Whether handling bulk or granular materials with bulk densities ranging from 0.5 to 2.5 t/m³ or constructing flexible conveyor systems, the belt feeder excels in meeting diverse operational line requirements, ensuring continuous and efficient material transport.

Table of Contents

Advantages and Features

Precise Adjustment and Flexible Adaptation

The belt feeder offers versatile production capacity adjustments. Users can control the speed by adjusting the variable frequency motor or by changing the insertion depth of the adjustment gate on the feeding hopper. This flexibility ensures that the material supply meets the requirements of different production stages.

Energy-Efficient and Low Noise

The belt feeder is designed to be energy-efficient and low-noise, which reduces energy consumption and creates a more comfortable working environment. Additionally, the straightforward operation process enhances work efficiency and reduces labor costs.

Easy Installation and High Capacity

The belt feeder is notable for its ease of installation and operation. It adapts quickly to various site conditions and provides large-capacity conveying, ensuring continuous operation of the production line and improving overall production efficiency.

Working Principle

The working principle of the belt feeder revolves around its core component—the belt. Material is fed onto the belt surface via the feeding hopper. As the variable frequency motor operates, the belt moves forward at a controlled speed. The material on the belt is then conveyed forward until it reaches the first roller and is fed into the subsequent process, achieving continuous material feeding.

This process ensures smooth material transition and allows precise control of the production flow through careful adjustment of speed and feed rate.

Technical parameters

| Model | Belt width (mm) | Center distance (mm) | Diameter (mm) | Capacity (t/h) | Feeding particle size (mm) | Motor model | Motor power (kw) | Weight (kg) |

| 500X1000 | 500 | 1000 | 219 | 10~100 | 0~50 | YCT112- 4B | 0.75 | 266 |

| 500X1300 | 500 | 1300 | 219 | 10~100 | 0~50 | YCT160 -4A | 2.2 | 503 |

| 500X1500 | 500 | 1500 | 219 | 10~100 | 0~50 | Y2.2-1.0-50-32 | 2.2 | 552.7 |

| 500X2000 | 500 | 2000 | 219 | 10~100 | 0~50 | Y2.2-1.0-50-32 | 2.2 | 609.4 |

| 500X2800 | 500 | 2800 | 219 | 10~100 | 0~50 | YCT160- 4A | 2.2 | 670 |

| 500X3000 | 500 | 3000 | 219 | 10~100 | 0~50 | YCT160 -4A | 2.2 | 697 |

| 500X4000 | 500 | 4000 | 219 | 10~100 | 0~50 | YCT160- 4A | 2.2 | 736 |

| 650X1500 | 650 | 1500 | 219 | 10~100 | 0~50 | YCT160- 4A | 2.2 | 610 |

| 650X2600 | 650 | 2600 | 219 | 10~100 | 0~50 | YCT160- 4A | 2.2 | 636 |

| 650X4000 | 650 | 4000 | 219 | 10~100 | 0~50 | YCT160- 4A | 2.2 | 893 |

| 800X2000 | 800 | 2000 | 219 | 15~150 | 0~80 | YCT160- 4A | 2.2 | 721 |

| 800X3000 | 800 | 3000 | 219 | 15~150 | 0~80 | YCT200- 4B | 7.5 | 857.3 |

| 800X4000 | 800 | 4000 | 219 | 15~150 | 0~80 | YCT200- 4B | 7.5 | 1012 |

| 800X4500 | 800 | 4500 | 400 | 15~150 | 0~80 | YCT160- 4A | 2.2 | 1200 |

| 1000X2000 | 1000 | 2000 | 400 | 200~450 | 0~80 | YCT160- 4B | 3 | 1549 |

| 1000X2500 | 1000 | 2500 | 400 | 200~450 | 0 ~100 | YCT160- 4B | 3 | 2105 |

| 1000X6000 | 1000 | 6000 | 400 | 200~450 | 0 ~100 | YCT225- 4A | 11 | 5214 |