Product Introduction

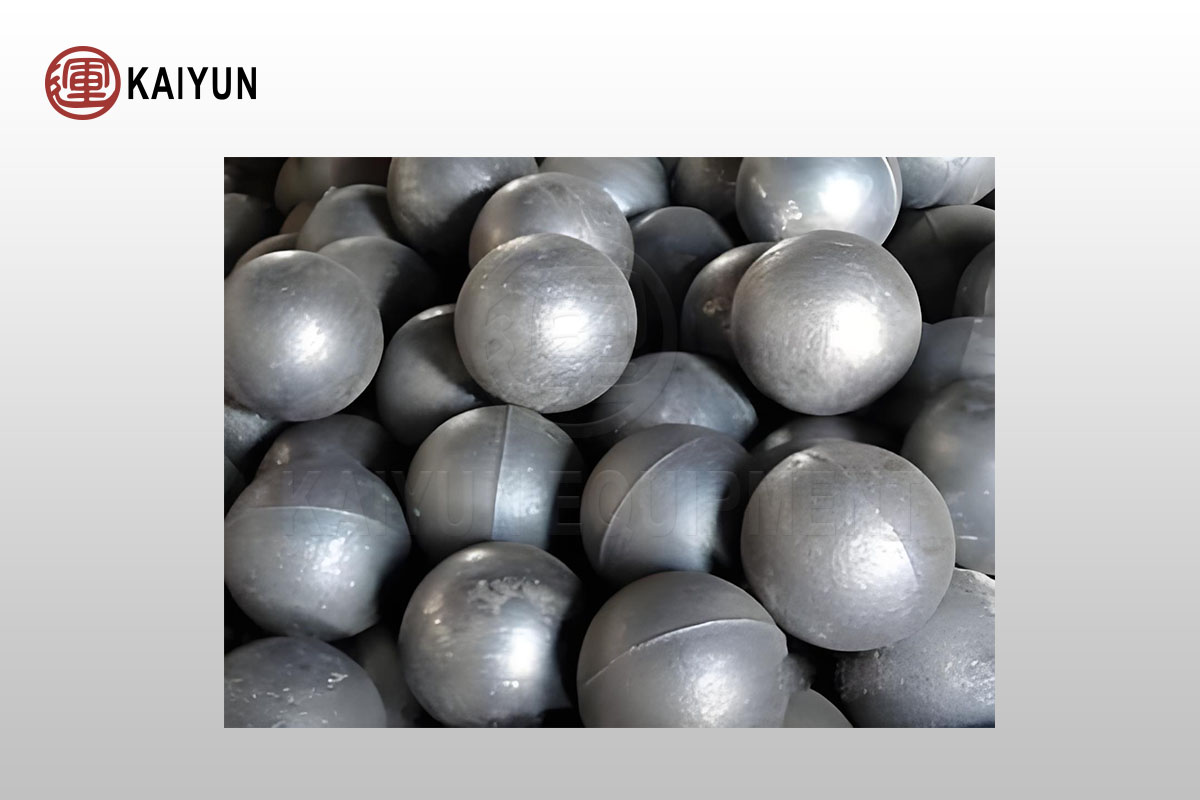

Cast steel balls are produced by melting scrap steel, iron, and other waste materials in an intermediate frequency electric furnace. Valuable metal alloys are added to adjust the chemical composition. The molten iron is then poured into molds or onto production lines, where it undergoes heat treatment processes such as quenching and tempering to achieve the desired properties.

This production method not only makes full use of recycled metal resources, promoting resource circularity but also enhances the wear resistance and strength of the steel balls through the addition of alloying elements.

Table of Contents

Product Classification and Characteristics

Cast steel balls are classified based on their alloy content:

High-Chromium Alloy Cast Balls

Characteristics

These balls contain a high percentage of chromium, offering excellent wear resistance and corrosion resistance.

Applications

Ideal for high-abrasion environments where durability and longevity are critical.

Medium-Chromium Alloy Cast Balls

Characteristics

With a moderate chromium content, these balls balance wear resistance with cost-effectiveness.

Applications

Suitable for general abrasion environments where a compromise between performance and cost is needed.

Low-Chromium Alloy Cast Balls

Characteristics

These balls have a lower chromium content, resulting in a lower cost while still providing adequate performance.

Applications

Best for light-abrasion environments or applications where cost sensitivity is a major factor.

Application Fields

Cast steel balls are mainly used in dry grinding fields, such as cement plants, chemical plants, power plants, quartz sand plants, silica sand plants, etc., among which the cement industry is the largest application market. In these industries, cast steel balls are used as grinding media to crush and refine various materials, and their wear resistance and economy are the key factors in selection.

Core Advantages

Cost-Effectiveness

Cast steel balls offer a good balance between cost and performance, particularly in dry grinding applications. Their economic advantage is significant, making them a popular choice for many industries.

Wide Applicability

Available in low, medium, and high chromium alloy options, cast steel balls meet varying levels of abrasion and cost requirements, making them suitable for a diverse range of dry grinding applications.

Resource Recycling

By using scrap metal as raw material, cast steel balls embody the principles of a circular economy, reducing resource waste and environmental pollution.