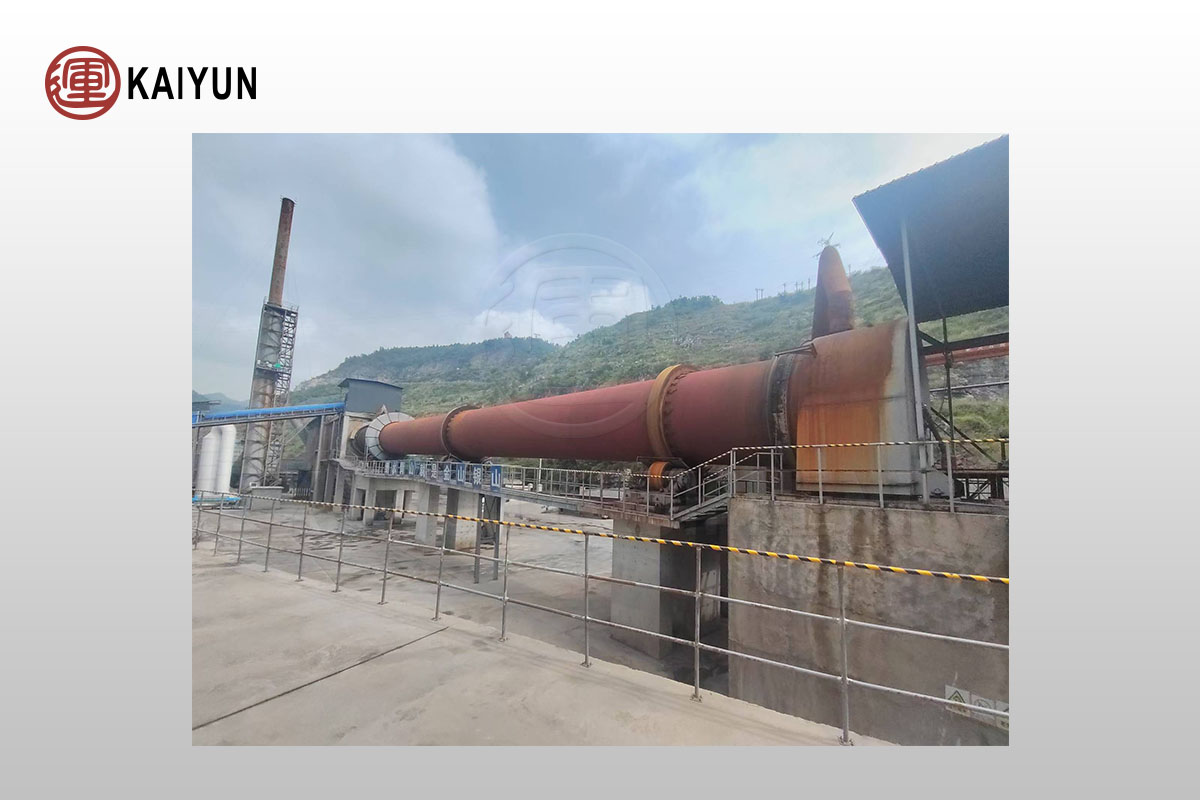

Product Introduction

The cement rotary kiln is one of the key equipment in cement production. It is mainly used for high-temperature calcination of cement clinker and is the core link of the “burning” stage in the cement manufacturing process. The rotary kiln converts raw materials into clinker through high-temperature calcination and is an indispensable equipment in the modern cement industry. The high efficiency and continuous working ability of the cement rotary kiln make it the basis for large-scale cement production.

The structural composition of the cement rotary kiln: rotary cylinder, transmission device, support wheel device, combustion device, feeding and discharging device, cooling system and exhaust gas treatment system.

Table of Contents

Working Principle

The cement rotary kiln is a large cylindrical equipment with an inclined angle. The cylinder can rotate slowly, and the material moves slowly forward in the kiln through gravity and the rotation of the kiln body. In this process, the raw material is subjected to the high temperature, chemical reactions occur, and cement clinker is formed. Its working principle is as follows:

1. Feeding: The raw material enters the kiln head of the rotary kiln after being preheated by the preheater.

2. High-temperature calcination: The raw material undergoes a series of chemical reactions in the rotary kiln, mainly at a high temperature of 850℃ to 1450℃, calcium carbonate decomposes into calcium oxide, and combines with silicates, aluminates, etc. to form cement clinker.

3. Cooling: The calcined clinker is discharged from the kiln tail and quickly cooled by the cooler to maintain its physical and chemical properties.

4. Tail gas treatment: The exhaust gas generated in the kiln is discharged through the preheater and dust removal device, and the exhaust gas is treated to meet environmental protection standards.

Application

1. Cement production

Cement rotary kiln is mainly used for calcining cement clinker and is widely used in the production of large cement plants.

2. Lime calcination

Cement rotary kiln can also be used for calcining limestone to produce quicklime, which is widely used in steel, chemical and other industries.

3. Metallurgical industry

Rotary kiln is used for smelting metal ores, roasting bauxite, etc., and is also often used for redox roasting.

4. Environmental protection treatment

Cement rotary kiln can also be used for waste treatment, such as incineration or resource treatment of solid waste.

Advantages

1. Efficient and continuous production: The rotary kiln can achieve large-scale continuous production to meet the high-output requirements of the modern cement industry.

2. High thermal energy utilization: Through the design of the preheater and cooling device, the rotary kiln can make full use of the thermal energy in the exhaust gas and reduce energy consumption.

3. Stable product quality: The rotary kiln has precise temperature control and can produce cement clinker with stable quality, ensuring the strength and durability of cement.

4. Good environmental protection: Modern cement rotary kilns are equipped with a complete exhaust gas treatment system, which can effectively control pollutant emissions and meet strict environmental protection standards.

Process Flow

1. Raw material preparation

Limestone, clay, iron ore powder and other raw materials are crushed, ground and mixed to make uniform raw material.

2. Preheating decomposition

Before entering the rotary kiln, the raw material is preheated by exhaust gas through the preheater to decompose part of the carbonate components and reduce the heat consumption in the kiln.

3. Calcination into clinker

The raw material enters the rotary kiln and undergoes a chemical reaction at high temperature to produce cement clinker.

4. Clinker cooling

The calcined clinker is quickly cooled by the cooler to keep its inherent mineral structure, which is convenient for subsequent cement preparation.

5. Waste gas treatment

The waste gas generated by the rotary kiln is discharged after dust removal, desulfurization and denitrification treatment to meet environmental protection requirements.