Product Introduction

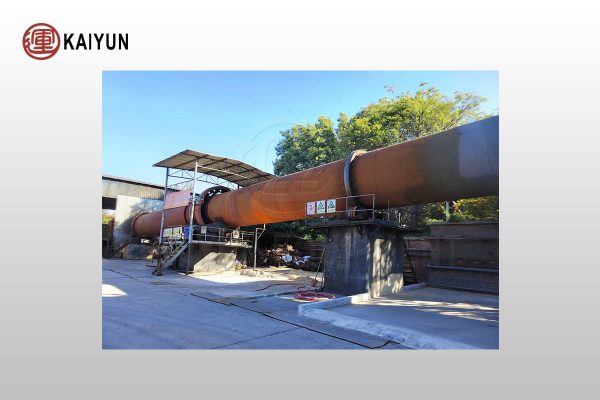

Ceramic rotary kiln is a high-temperature heat treatment equipment specially used for the production of ceramsite. This type of rotary kiln is a plug-in double-drum rotary kiln. The preheating kiln is used for drying and preheating, and the roasting kiln is used for firing. It is mainly composed of a rotary drum, a transmission device, a support device, a feeding and discharging device, a combustion system and a cooling system.

Ceramic rotary kiln is mainly used to roast ceramsite raw materials, and the raw materials are processed into ceramsite products with certain strength, density and durability through high temperature. It is widely used in building materials, metallurgy, chemical industry, environmental protection and other industries.

Table of Contents

Working principle

Ceramic rotary kiln is a cylindrical equipment with a certain slope, usually installed on a supporting wheel and can rotate. The ceramsite raw materials are fed into the rotary kiln through the kiln head feeding device, and move downward by gravity in the rotary kiln, passing through the three main areas of the preheating zone, roasting zone and cooling zone. In this process, the raw materials undergo chemical and physical reactions at high temperature to form the final ceramsite product.

Advantages

High production efficiency: continuous operation, large output, can meet the needs of large-scale production.

Flexible operation: The temperature, speed and other parameters of the rotary kiln can be adjusted to adapt to different types of raw materials and process requirements.

Good product quality: By precisely controlling the temperature and roasting time, the ceramsite products produced have stable performance, good strength and durability.

Environmental protection and energy saving: Modern ceramsite rotary kilns are usually equipped with exhaust gas treatment and waste heat recovery systems to reduce the impact on the environment and reduce energy consumption.

Application areas

Building materials

Ceramsite is mainly used to produce lightweight concrete, ceramsite concrete blocks, etc., with excellent thermal insulation, sound insulation and seismic resistance.

Gardening

Ceramsite is widely used as a horticultural substrate for soilless cultivation of plants and to improve soil permeability.

Sewage treatment

Ceramsite is often used as a filter material in sewage treatment due to its porous structure, which can effectively filter suspended matter and organic matter.

Insulation materials

The light weight and thermal insulation properties of ceramsite make it an ideal choice for building insulation materials.