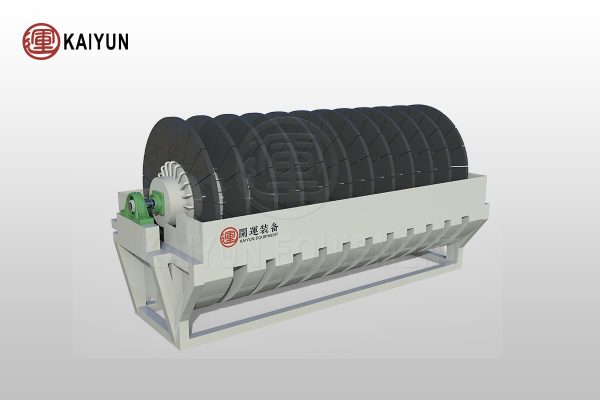

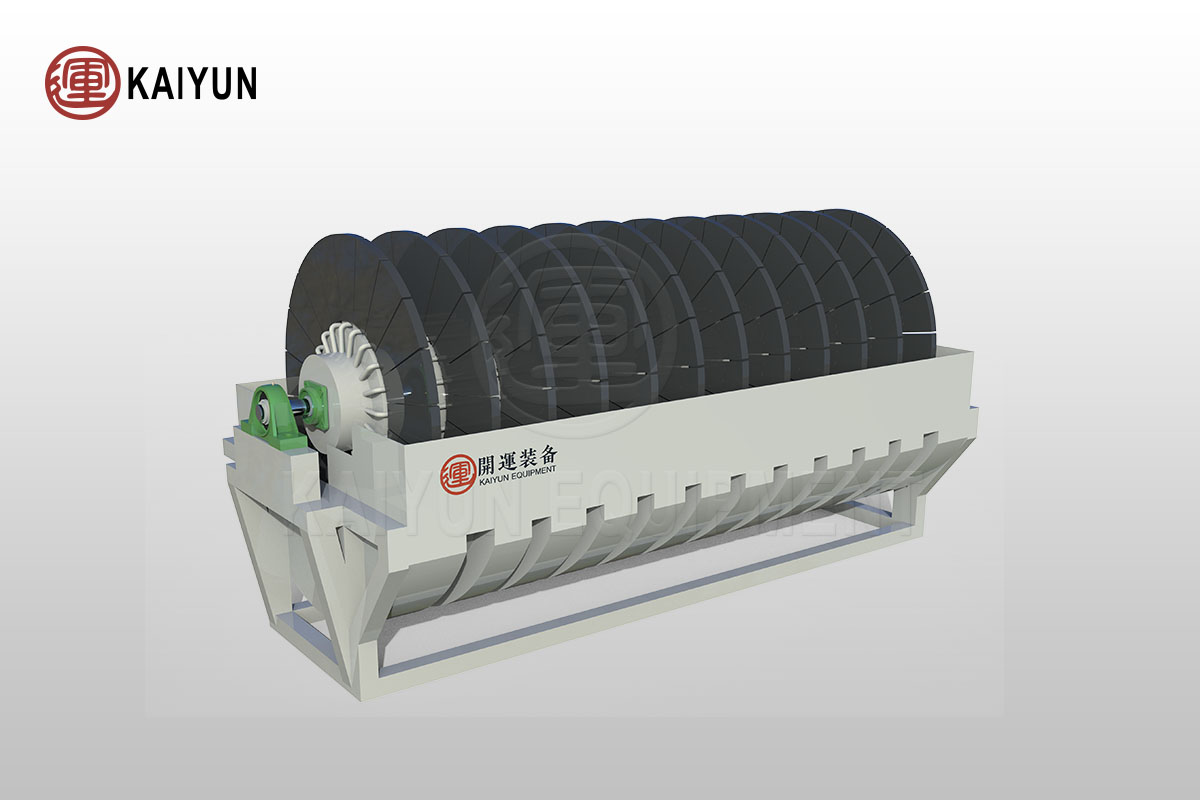

Product Introduction

The Ceramic Vacuum Filter is an advanced filtration device that relies on microporous ceramics for vacuum dewatering.

The Ceramic Vacuum Filter has become an ideal choice for dewatering concentrates and tailings in mining (including non-ferrous metals, rare metals, black metals, and non-metals), dewatering of oxides, electrolytic slag, leaching residues, and furnace slag in the chemical industry, and treatment of wastewater, sludge, and waste acids in environmental protection.

The Ceramic Vacuum Filter unique microporous ceramic filtering medium demonstrates a significant energy-saving potential, with energy consumption reduced by over 90% compared to traditional filtration technologies, highlighting its substantial advantages in energy conservation and emission reduction.

Advantages and Features

High-Efficiency Vacuum Dewatering

With a high vacuum level (0.09–0.098 MPa), the ceramic vacuum filter ensures minimal moisture in the filter cake, significantly improving dewatering efficiency.

Clean and Recyclable

The treated filtrate has a low solid content of less than 50 ppm, enabling recycling and reducing emissions, reflecting its commitment to environmental protection.

Filter Cake Washing Function

Compared to traditional ceramic filters, it includes a filter cake washing function, making it suitable for materials that require washing and expanding its range of applications.

Automated Control and Operation

Equipped with PLC and microcomputer-based automatic valve control, the filter boasts high automation, significantly reducing labor intensity and enhancing production efficiency.

Compact Design and Cost Savings

The compact structure of the ceramic vacuum filter saves space and is easy to install and maintain. It is cost-effective with low operational costs, especially compared to filter press equipment, saving over 90% in energy consumption, demonstrating significant economic benefits.

Wide Range of Material Handling

Capable of processing materials with fineness ranging from -200 to -450 mesh and various ultrafine materials, it offers strong adaptability to meet filtration needs across different industries.

Working Principle

The ceramic vacuum filter comprises several key systems, including the roller system, stirring system, feed and discharge system, vacuum system, filtrate discharge system, scraping system, backwashing system, combined cleaning system (ultrasonic cleaning, automatic acid cleaning), fully automatic control system, tank body, and frame.

During operation

Filtration Process: The filter plate, under the combined effects of capillary action and vacuum pressure, forms a layer of filter cake in the slurry suction zone. The filtrate passes through the filter plate into the distribution valve and is finally discharged into the filtrate tank.

Washing and Dewatering

After the filter cake is transferred from the slurry discharge hopper, it enters the washing zone for spray washing. Subsequently, it continues to dewater in the drying zone under high vacuum pressure.

Discharge

In the discharge zone, the filter cake is automatically removed by a scraper in the absence of vacuum.

Backwashing

Industrial water or filtrate is directed through the distribution valve into the ceramic plate for internal-to-external cleaning, ensuring the ceramic plates remain clear and unobstructed.

Combined Cleaning

After one cycle of use, ultrasonic cleaning combined with low-concentration acid is employed to clean the ceramic plates, ensuring their effective use and extending the equipment’s lifespan.

Technical parameters

| Model | Filter area/㎡ | Filter disc/ring | Number of filter plates/piece | Volume of tank/m³ | Installed power/kw | Operating power/kw | Host (L*W*H)/m |

| CVF-1 | 1 | 1 | 12 | 0.21 | 3.5 | 2.0 | 1.6*1.4*1.5 |

| CVF-4 | 4 | 2 | 24 | 1.0 | 7.0 | 3.0 | 2.4*2.5*2.1 |

| CVF-6 | 6 | 2 | 24 | 1.2 | 7.0 | 6.0 | 2.4*2.9*2.5 |

| CVF-9 | 9 | 3 | 36 | 1.7 | 9.0 | 7.0 | 2.7*2.9*2.5 |

| CVF-12 | 12 | 4 | 48 | 2.2 | 11.0 | 7.5 | 3.0*2.9*2.5 |

| CVF-15 | 15 | 5 | 60 | 2.7 | 11.5 | 8.0 | 3.3*3.0*2.5 |

| CVF-21 | 21 | 7 | 84 | 4.0 | 13.5 | 9.0 | 4.6*3.0*2.6 |

| CVF-24 | 24 | 8 | 96 | 4.5 | 16.5 | 10.5 | 4.9*3.0*2.6 |

| CVF-27 | 27 | 9 | 108 | 5.0 | 17.0 | 11.0 | 5.2*3.0*2.6 |

| CVF-30 | 30 | 10 | 120 | 5.5 | 17.5 | 11.5 | 5.5*3.0*2.6 |

| CVF-36 | 36 | 12 | 144 | 7.0 | 23.0 | 16.0 | 6.6*3.0*2.6 |

| CVF-45 | 45 | 15 | 180 | 8.5 | 25.0 | 19.0 | 7.5*3.0*2.6 |

| CVF-60 | 60 | 15 | 180 | 12.5 | 33.0 | 22.0 | 7.5*3.3*3.0 |

| CVF-80 | 80 | 20 | 240 | 16.2 | 40.0 | 24.0 | 9.0*3.3*3.0 |

| CVF-102 | 102 | 17 | 204 | 18.5 | 53.0 | 35.0 | 8.8*3.6*3.3 |

| CVF-120 | 120 | 20 | 240 | 20 | 60.0 | 40.0 | 9.7*3.6*3.3 |

| CVF-150 | 150 | 25 | 300 | 24 | 75.0 | 47.0 | 11.2*3.6*3.3 |