Product Introduction

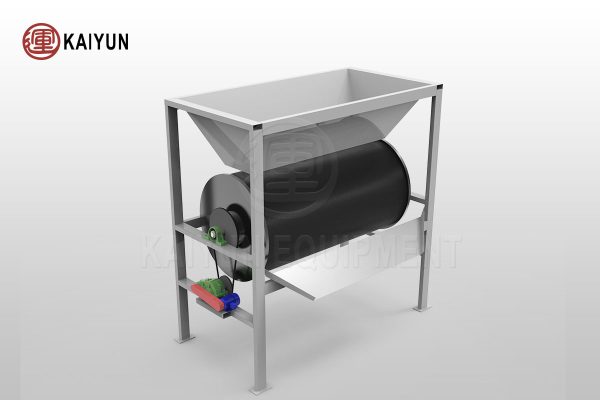

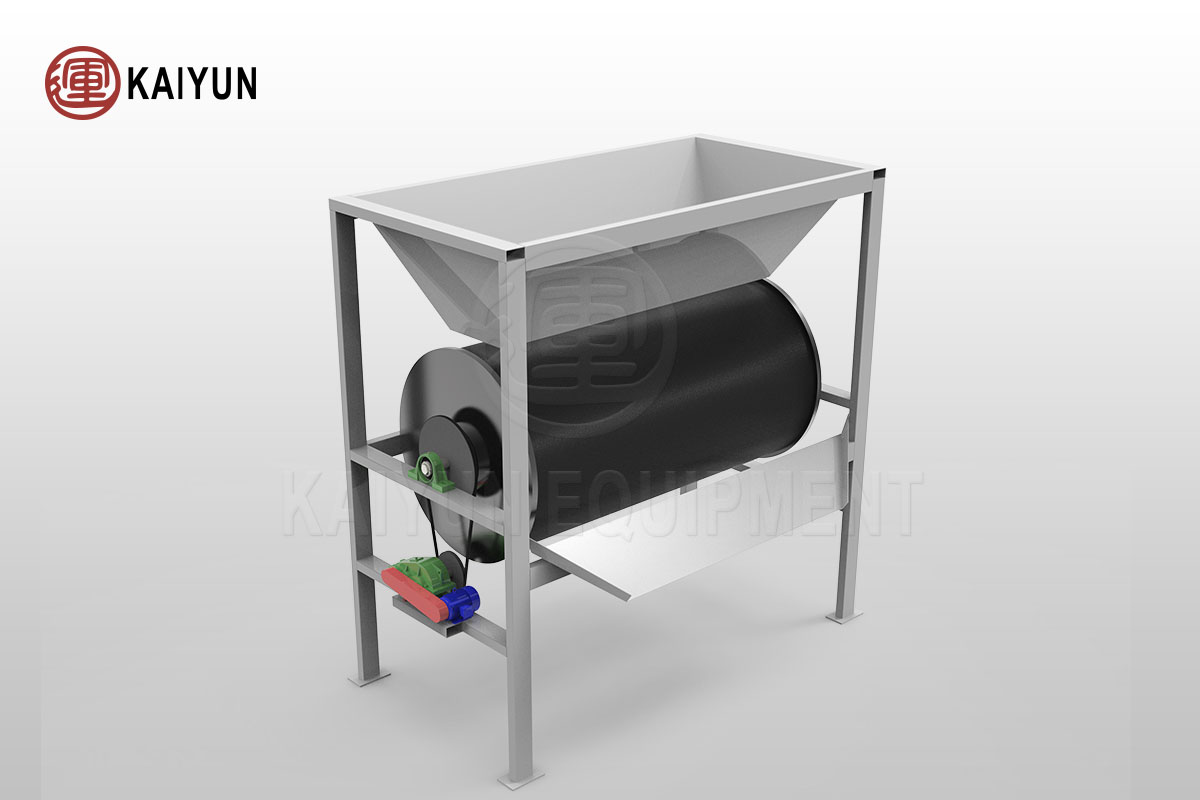

The CTG Magnetic Drum is a dry magnetic separation device specifically designed for the pre-selection of coarse, strongly magnetic minerals.

The CTG Magnetic Drum is particularly suitable for the dry pre-selection of magnetite before grinding, capable of handling materials with particle sizes up to 300mm.

The CTG Magnetic Drum unique large magnetic wrap angle design (magnetic wrap angle < 180°) increases the length of the separation zone and the number of magnetic flips, effectively achieving the separation of magnetic minerals from non-magnetic (or weakly magnetic) minerals.

Table of Contents

This significantly improves the feed grade for grinding to above geological grade, while also discarding a suitable amount of tailings, thus optimizing the beneficiation process.

Working Principle

The CTG Magnetic Drum operates as the driving drum of a conveyor belt. As materials pass over the magnetic drum on the conveyor belt, magnetic and non-magnetic materials are separated. Magnetic materials are attracted by the magnetic force as they approach the drum, moving to the top of the drum. As the drum rotates, the magnetic materials reach the bottom and automatically fall off. Non-magnetic materials, unaffected by the magnetic force, follow a horizontal parabolic trajectory and fall directly down. Magnetic and non-magnetic materials are collected into different receiving hoppers, achieving efficient separation.

Advantages and Features

High-Performance Magnetic System Materials

The CTG Magnetic Drum uses high-performance neodymium iron boron magnets with high magnetic energy product and high coercivity. This ensures strong magnetic field intensity and depth of action, with a demagnetization rate of no more than 5% within 8 years, guaranteeing long-term stable magnetic separation.

Durable and Safe Design

The magnetic system is coated with non-magnetic stainless steel, effectively preventing magnet detachment and enhancing the equipment’s reliability. The drum is made of non-magnetic stainless steel and lined with wear-resistant rubber, significantly extending the drum’s service life and reducing maintenance costs.

Flexible Installation Options

The CTG Magnetic Drum can be used as either a driving drum or a driven drum, offering users more installation and configuration options to meet different production needs.

Technical Parameters

| Model | Drum Diameter (mm) | Drum Length (mm) | Belt Width (mm) | Magnetic Field Intensity (mt) | Processing Capacity (t/h) | Feed Particle Size (mm) | Total Weight (t) |

| CTG0812 | 800 | 1200 | 1000 | 300~500 | ≤100 | ≤200 | 2.1 |

| CTG0814 | 800 | 1400 | 1200 | 300~500 | ≤120 | ≤200 | 2.6 |

| CTG0816 | 800 | 1600 | 1400 | 300~500 | ≤150 | ≤200 | 3.2 |

| CTG0818 | 800 | 1800 | 1600 | 300~500 | ≤180 | ≤200 | 3.9 |

| CTG1018 | 1000 | 1800 | 1600 | 300~500 | ≤270 | ≤250 | 4.4 |

| CTG1218 | 1200 | 1800 | 1600 | 300~500 | ≤350 | ≤300 | 5.0 |