Product Introduction

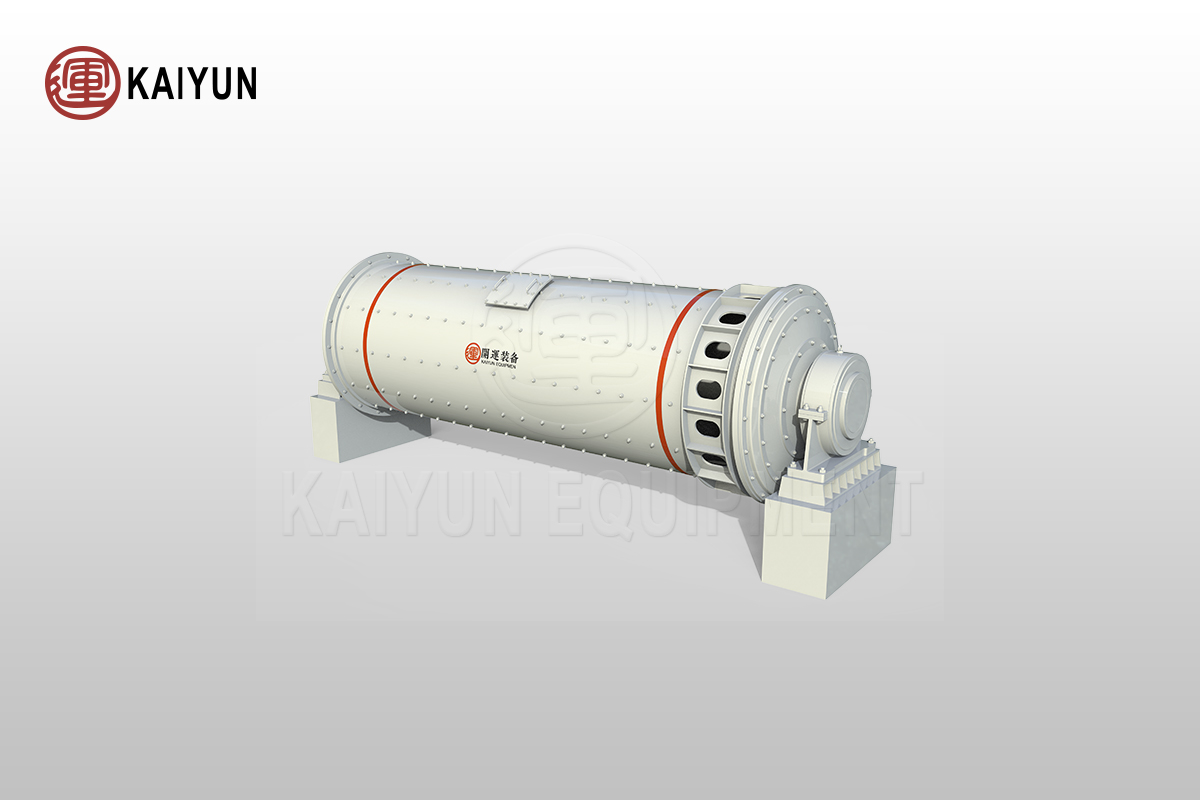

The dry ball mill is a specialized equipment designed for processing dry materials, widely used in industries such as mineral processing, building materials, metallurgy, and chemicals. It demonstrates exceptional capabilities, especially in the processing of metal ores.

The dry ball mill design features a horizontal cylindrical rotating structure, supplemented by external gear transmission, and is divided into two working chambers. With its grate discharge characteristics, it provides an ideal environment for the fine grinding of dry materials.

Table of Contents

Advantages and Features

Wide Material Applicability

The dry ball mill boasts a strong adaptability to various materials, enabling continuous production and easy adjustment of product fineness to meet the individualized particle size requirements of different industries.

Efficient Dust Removal Performance

The discharge port features a cylindrical design, paired with an induced draft device, significantly enhancing dust removal effectiveness. This ensures a clean working environment and reduces dust damage to the equipment.

Flexible Production Modes

It can independently perform open-flow milling or work in conjunction with a powder concentrator to form a closed-circuit milling process, increasing production flexibility and efficiency.

Various Configuration Options

Depending on material characteristics and discharge methods, users can choose between overflow-type or grate-type dry ball mills to suit different production process requirements.

Direct Output of Qualified Materials

After dry milling, the materials reach the required particle size standard without the need for additional screening steps, simplifying the production process.

Selectable Rotation Directions

Based on the production line layout, the dry ball mill can be configured for left-hand or right-hand rotation, offering greater freedom in plant design.

Easy Maintenance

The dry ball mill features a simple structural design, making it easy to maintain. The hollow shaft is made of high-strength cast steel, and the liners are easy to replace, reducing maintenance costs and downtime.

Working Principle

The material is uniformly fed into the first chamber of the mill through the feeding device. This chamber is equipped with a step liner or corrugated liner, along with steel balls of various specifications. As the cylinder rotates, the steel balls are lifted to a certain height by centrifugal force and then fall down, striking and grinding the material.

After coarse grinding in the first chamber, the material passes through a single-layer partition board into the second chamber, which is equipped with a flat liner and steel balls for further fine grinding. Finally, the powdered material is discharged through the discharge grate, completing the entire grinding process and directly obtaining the finished product that meets the required standards.

Technical Parameters

| Model | Drum Speed (r/min) | Ball Load (t) | Feeding Size (mm) | Discharge Size (mm) | Capacity (t/h) | Motor Power (kw) | Weight (t) |

| Ф900×1800 | 36-38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.85 |

| Ф900×3000 | 36 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.98 |

| Ф1200×2400 | 36 | 3 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 | 13.6 |

| Ф1200×3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 14.3 |

| Ф1200×4500 | 32.4 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 |

| Ф1500×3000 | 29.7 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 19.5 |

| Ф1500×4500 | 27 | 11 | ≤25 | 0.074-0.4 | 3-6 | 110 | 22 |

| Ф1500×5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Ф1830×3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 | 34.5 |

| Ф1830×4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 | 38 |

| Ф1830×6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Ф1830×7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Ф2100×3000 | 23.7 | 15 | ≤25 | 0.074-0.4 | 6.5-36 | 155 | 45 |

| Ф2100×4500 | 23.7 | 24 | <25 | 0.074-0.4 | 8-43 | 245 | 56 |

| Ф2100×7000 | 23.7 | 26 | <25 | 0.074-0.4 | 12-48 | 280 | 59.5 |

| Ф2200×4500 | 21.5 | 27 | <25 | 0.074-0.4 | 9-45 | 280 | 54.5 |

| Ф2200×6500 | 21.7 | 35 | <25 | 0.074-0.4 | 14-26 | 380 | 61 |

| Ф2200×7000 | 21.7 | 35 | <25 | 0.074-0.4 | 15-28 | 380 | 62.5 |

| Ф2200×7500 | 21.7 | 35 | <25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Ф2400×3000 | 21 | 23 | <25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Ф2400×4500 | 21 | 30 | <25 | 0.074-0.4 | 8.5-60 | 320 | 72 |

| Ф2700×4000 | 20.7 | 40 | <25 | 0.074-0.4 | 22-80 | 380 | 95 |

| Ф2700×4500 | 20.7 | 48 | <25 | 0.074-0.4 | 26-90 | 480 | 102 |

| Ф3200×4500 | 18 | 65 | <25 | 0.074-0.4 | – | 630 | 149 |

| Ф3600×4500 | 17 | 90 | <25 | 0.074-0.4 | – | 850 | 169 |

| Ф3600×6000 | 17 | 110 | <25 | 0.074-0.4 | – | 1250 | 198 |