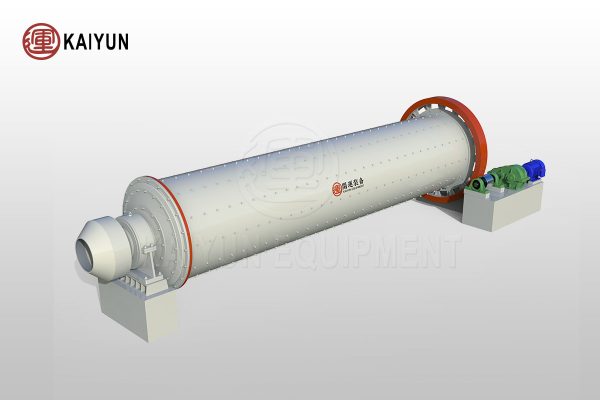

Product Introduction

The energy-saving overflow ball mill is a modern grinding device that combines high efficiency and excellent performance, is specifically designed for processing fine-grained ores.

The energy-saving overflow ball mill is widely used in industries such as mining, building materials, and chemicals. Its innovative design concepts and advanced technological applications provide users with a more economical and environmentally friendly grinding experience.

Table of Contents

Advantages and Features

Innovative Rolling Bearings

The use of large double-row self-aligning roller bearings replaces traditional sliding bearings, significantly reducing friction resistance. This makes the equipment easier to start and reduces energy consumption by 20%-30%, demonstrating remarkable energy-saving effects.

Enhanced Grinding Efficiency

The use of wave-type liners increases the contact area between the balls and the ore, strengthening the grinding action while improving the lifting capacity of the ore. This effectively reduces energy consumption and enhances grinding efficiency.

Large Discharge Port Design

Equipped with a large discharge port, which significantly increases production capacity, ensuring a continuous and efficient production process.

Modular Frame

The integrated frame structure greatly facilitates civil construction and equipment installation, shortening project cycles and reducing engineering costs.

Intelligent Lubrication System

The oil mist lubrication device ensures full lubrication of the large and small gears, guaranteeing stable operation of the equipment and extending its service life.

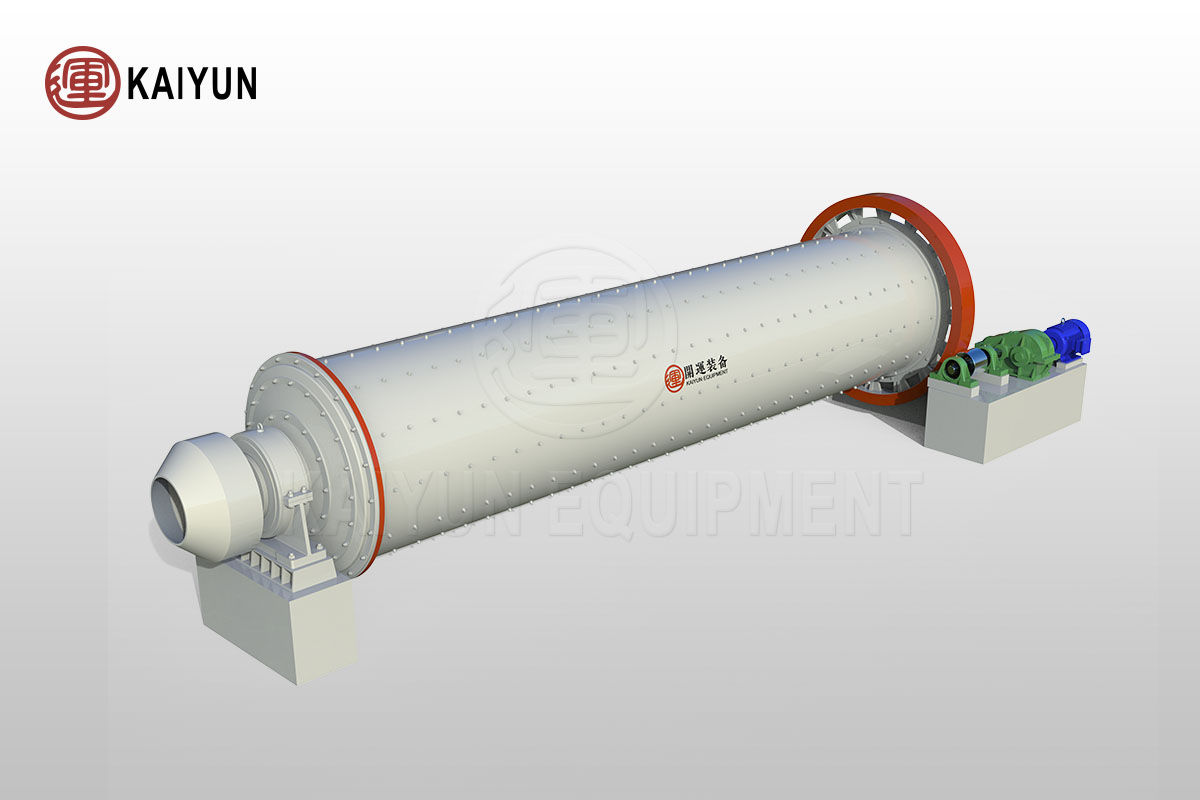

Working Principle

The energy-saving overflow ball mill operates by supporting the drum with rolling bearings and using a drive mechanism to slowly rotate the drum. Materials are continuously fed from the feed end, and inside the drum, the steel balls and ores achieve material pulverization through cascading impacts and self-grinding actions. As new materials are continuously added, the materials inside the drum naturally move from the feed end to the discharge end under pressure. When the slurry level exceeds the lower edge of the hollow shaft at the discharge end, it automatically overflows and discharges.

Notably, the hollow shaft is equipped with anti-spiral blades, which effectively guide the overflowing steel balls and coarse ore particles back into the mill, preventing resource waste.

This ball mill features a compact structure, consisting of a feeding part, main bearing, rotating part, drive part (including large and small gears), air clutch, main motor, slow transmission device, jacking device, and comprehensive lubrication and electrical control systems. These components ensure the equipment operates efficiently and stably.

Technical Parameters

| Model | Drum Diameter (mm) | Drum Length (mm) | Motor Model | Motor Power (kw) | Length (mm) | Width (mm) | Height (mm) | Capacity (t/h) | Volume (m³) | Ball Load (t) | Weight(kg) |

| MQYG 0912 | 900 | 1200 | Y1800L-6 | 15 | 3666 | 1835 | 1400 | 0.25~1.2 | 0.7 | 1 | 4265 |

| MQYG 0918 | 900 | 1800 | Y225M-8 | 22 | 4401 | 2535 | 2070 | 0.25~1.6 | 0.9 | 1.66 | 5235 |

| MQYG 1212 | 1200 | 1200 | Y200L2-6 | 22 | 3512 | 2076 | 1620 | 0.17 ~4.1 | 1.14 | 1.9 | 9610 |

| MQYG 1224 | 1200 | 2400 | Y280M-8 | 45 | 5745 | 2352 | 1778 | 0.26~6.15 | 2.4 | 4.8 | 12219 |

| MQYG 1240 | 1200 | 4000 | JR117-8 | 80 | 7990 | 2412 | 1728 | 0.34 ~8.3 | 3.7 | 7.8 | 15600 |

| MQYG 1515 | 1500 | 1500 | Y280M-8 | 45 | 5740 | 3075 | 2280 | 1.4 ~4.5 | 2.2 | 4.2 | 17125 |

| MQYG 1530 | 1500 | 3000 | JR117-8 | 80 | 7253 | 3070 | 2280 | 2.8 ~9 | 5 | 10 | 21129 |

| MQYG 1536 | 1500 | 3600 | JR126-8 | 110 | 8595 | 3185 | 2280 | 2.8 ~10 | 5.4 | 10 | 23933 |

| MQYG 1545 | 1500 | 4500 | JR127-8 | 130 | 9680 | 3254 | 2370 | 3.5~12.5 | 7 | 12 | 27500 |

| MQYG 1557 | 1500 | 5700 | JR127-8 | 130 | 10880 | 3254 | 2370 | 4.5 ~16 | 8.9 | 15 | 29359 |

| MQYG 1836 | 1800 | 3620 | JR136-8 | 180 | 8865 | 3683 | 2785 | 4.5 ~29 | 8.2 | 13.8 | 34970 |

| MQYG 1845 | 1800 | 4520 | JR137-8 | 210 | 9750 | 3683 | 2785 | 5~33 | 10.2 | 19 | 37480 |

| MQYG 1857 | 1830 | 5720 | JR137-8 | 210 | 11009 | 3683 | 2785 | 6~40 | 12.5 | 22 | 42096 |

| MQYG 1863 | 1800 | 6320 | JR138-8 | 320 | 11690 | 3781 | 2775 | 6~45 | 14.2 | 25 | 45520.5 |

| MQYG 1870 | 1800 | 7020 | JR138-8 | 245 | 12599 | 3783 | 2735 | 7~47 | 15 | 31.5 | 45136 |

| MQYG 1875 | 1800 | 7500 | JR138-8 | 245 | 12850 | 3783 | 2775 | 7.5 ~54 | 17 | 30 | 49450 |

| MQYG 2122 | 2100 | 2200 | JR128-8 | 155 | 7235 | 4120 | 3083 | 5~29 | 6.6 | 20 | 35963 |

| MQYG 2130 | 2100 | 3000 | JR136-8 | 180 | 8220 | 4220 | 3083 | 6.5 ~36 | 9 | 27 | 40157 |

| MQYG 2136 | 2100 | 3600 | JR137-8 | 210 | 8958 | 4320 | 3025 | 7.5 ~42 | 10.8 | 23.5 | 44132.5 |

| MQYG 2145 | 2100 | 4500 | JR138-8 | 245 | 10350 | 4268 | 3121 | 10 ~45 | 13.5 | 23.6 | 42772 |

| MQYG 2430 | 2400 | 3000 | JR138-8 | 280 | 9023.5 | 4836.4 | 3490 | 7.2 ~92 | 11.5 | 22.5 | 57455.5 |

| MQYG 2436 | 2400 | 3600 | JR137-6 | 280 | 9623.5 | 4836.4 | 3490 | 8 ~110 | 13.8 | 25.5 | 60861.5 |

| MQYG2442 | 2400 | 4200 | JR138-8 | 320 | 10204.5 | 4836.4 | 3440 | 8 ~130 | 16.5 | 31.5 | 63829.5 |

| MQYG 2445 | 2400 | 4500 | JR1510-8 | 380 | 11132.5 | 5091.4 | 4065 | 8.5~140 | 17.5 | 31 | 75923 |

| MQYG 2460 | 2400 | 6000 | JR1510-8 | 450 | 12623.5 | 5201.4 | 4060 | 9 ~180 | 23 | 40 | 83869 |

| MQYG 2727 | 2700 | 2700 | JR137-6 | 280 | 8901 | 4786.4 | 3620 | 7 ~110 | 13.8 | 29 | 66201 |

| MQYG 2730 | 2700 | 3000 | JR137-6 | 280 | 9201 | 4786.4 | 3620 | 8 ~115 | 15.3 | 32 | 72415 |

| MQYG 2732 | 2700 | 3200 | JR1410-8 | 320 | 10729 | 5000 | 3620 | 8 ~120 | 15.7 | 32 | 83110 |

| MQYG 2736 | 2700 | 3600 | JR158-8 | 380 | 10764 | 5150 | 3620 | 12~145 | 17.7 | 37 | 90441 |

| MQYG 2740 | 2700 | 4000 | JR1510-8 | 380 | 10870 | 5050 | 3620 | 12.5 ~152 | 19 | 40 | 93441 |

| MQYG 2745 | 2700 | 4500 | JR1510-8 | 380 | 11664 | 5150 | 3620 | 12.5 ~163 | 20.5 | 40 | 96196 |

| MQYG 2747 | 2700 | 4700 | JR1510-8 | 400 | 11864 | 5150 | 3620 | 13~170 | 23 | 45 | 97605 |

| MQYG 3231 | 3200 | 3100 | TDMK630-36 | 630 | 12550 | 6750 | 5150 | 14~180 | 21.4 | 45 | 112430 |

| MQYG 3245 | 3200 | 4500 | TDMK630-36 | 630 | 13950 | 7200 | 5152.5 | 95~110 | 32.8 | 65 | 141629 |

| MQYG 3660 | 3600 | 6000 | TDMK1250-40 | 1250 | 19780 | 7700 | 5496 | 120~200 | 55 | 102 | 193483 |