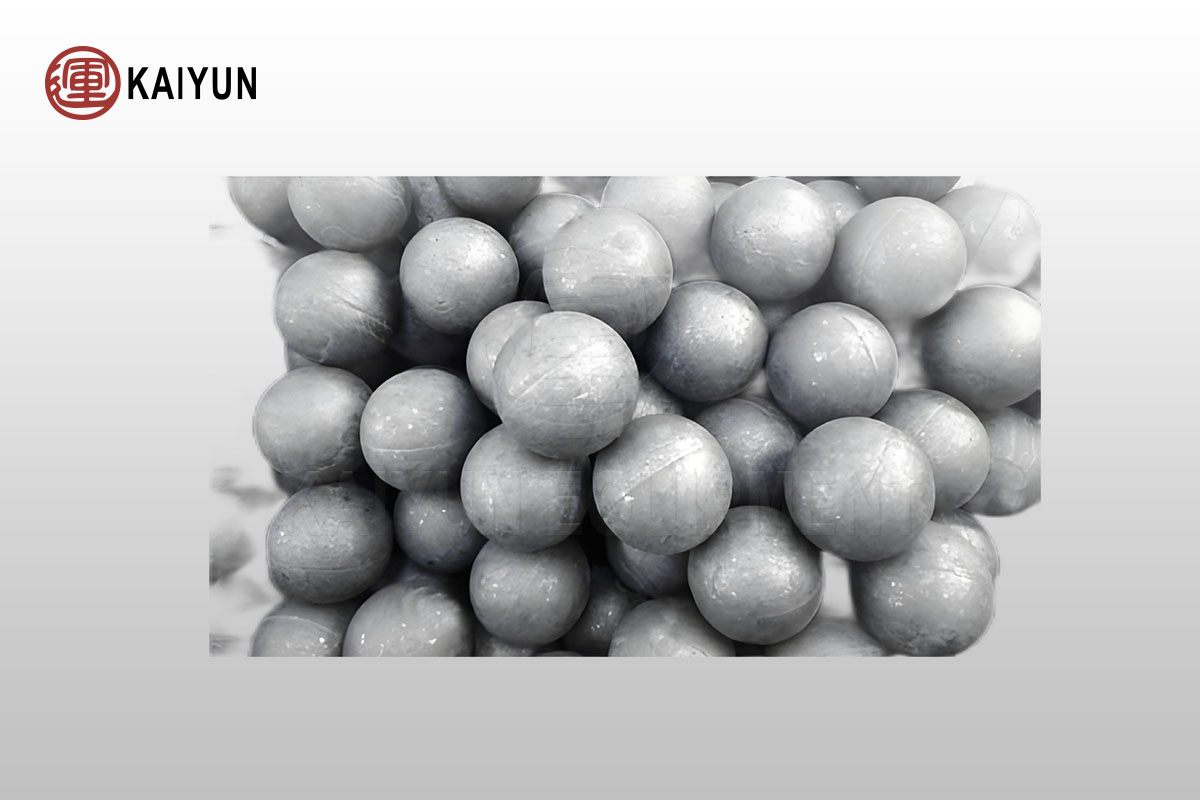

Product Introduction

Forged steel balls, as the name suggests, are steel balls formed through forging after direct high-temperature heating. Unlike traditional casting methods, forged steel balls do not undergo melting and casting steps but are directly shaped through hammering.

This manufacturing process not only eliminates potential porosity defects that may occur during smelting but also optimizes the microstructure, resulting in superior mechanical properties for the final product.

Table of Contents

Core Advantages and Features

Optimized Microstructure

The forging process eliminates defects such as porosity that can occur during smelting. Through plastic deformation during forging, the metal’s grain structure is preserved, resulting in mechanical properties that are significantly superior to cast products made from the same material.

Material Determines Wear Resistance

The wear resistance of forged steel balls is directly related to the material used. High-quality forged steel balls, such as those from Xinhai, use steel from major steel mills, offering excellent impact resistance, toughness, and wear resistance. They can withstand high-intensity grinding without easily breaking.

Application Fields

Forged steel balls are primarily used in wet grinding applications, such as the grinding processes for iron ore, copper ore, gold ore, and copper-lead-zinc ore. Their outstanding wear resistance and high strength make them an indispensable grinding medium in milling operations.