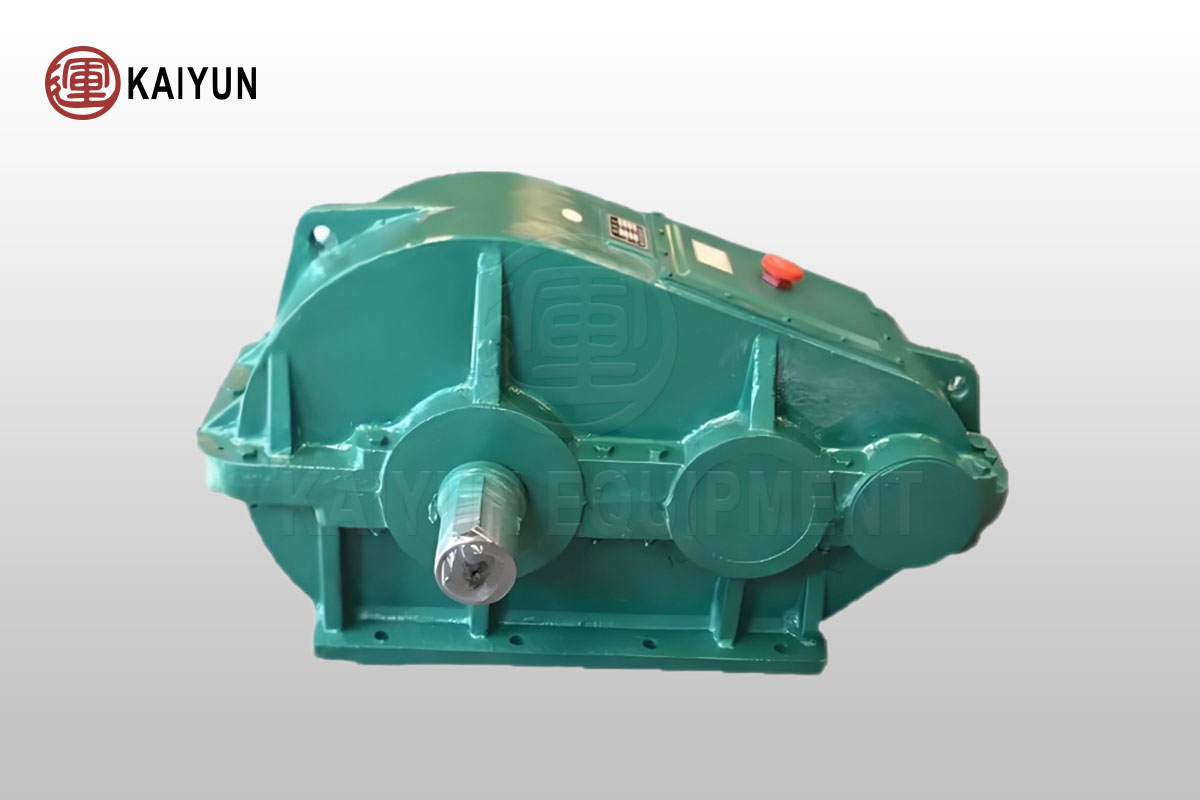

Product Introduction

As an indispensable transmission component in the field of industrial automation, the core function of the gear reducer is to reduce the rotational speed of the input shaft while increasing the torque of the output shaft, thereby meeting the various speed and power requirements of different mechanical equipment.

This process is typically achieved through a series of precisely designed gear sets or worm mechanisms within an enclosed steel housing, ensuring transmission stability and efficiency.

The gear reducer can significantly reduce speed by engaging a small gear on the input shaft with a larger gear on the output shaft, efficiently transmitting energy from the motor or other high-speed power sources.

Table of Contents

Core Advantages and Features

Speed Regulation and Torque Amplification

The gear reducer can effectively reduce the speed of the power source while significantly increasing the torque at the output end. This enables mechanical equipment to exhibit powerful driving force even at low speeds, enhancing the operational characteristics and working capabilities of the equipment.

Reduced Rotational Inertia

The use of a gear reducer can significantly reduce the system’s rotational inertia. This results in a more responsive system, allowing for faster and more precise control over the equipment’s start, stop, and speed changes, thereby improving overall control flexibility and efficiency.

Motor Protection

The gear reducer also serves to protect the motor. By absorbing most of the load and impact, the gear reducer reduces the stress directly applied to the motor, preventing overload, extending the motor’s lifespan, and reducing the risk of production interruptions caused by motor failure.