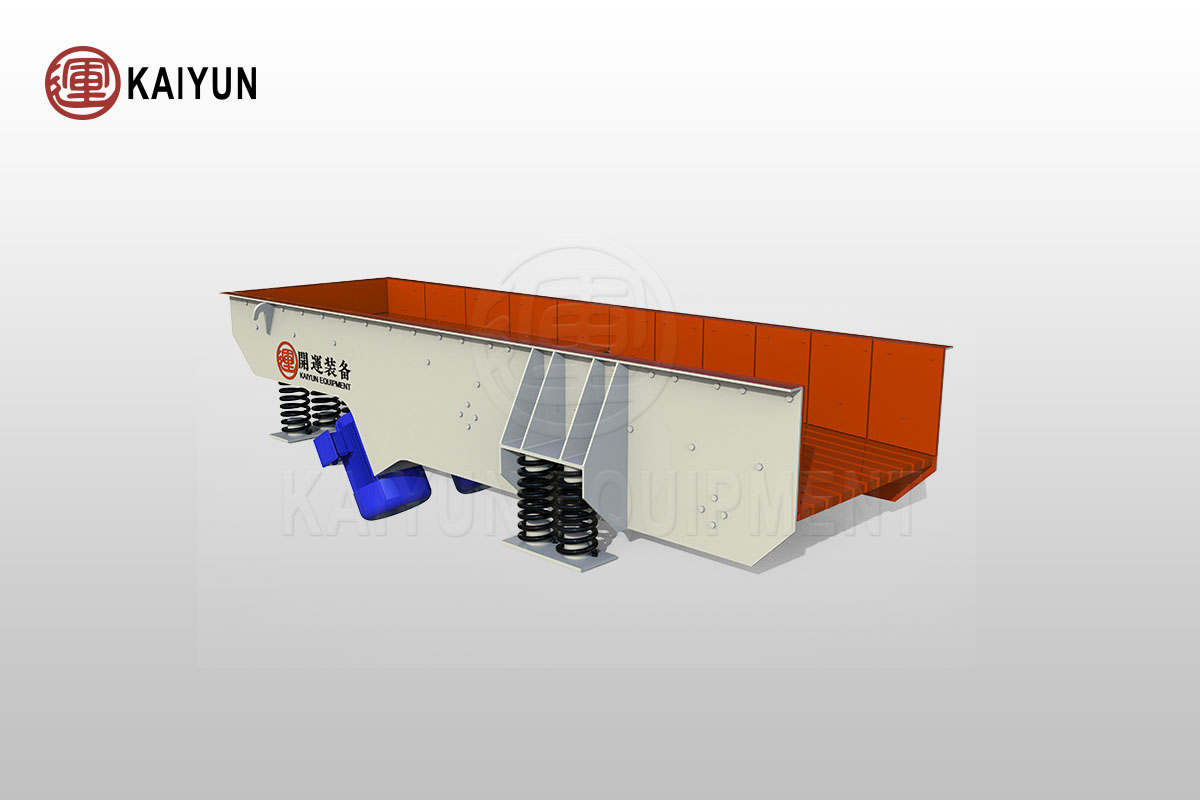

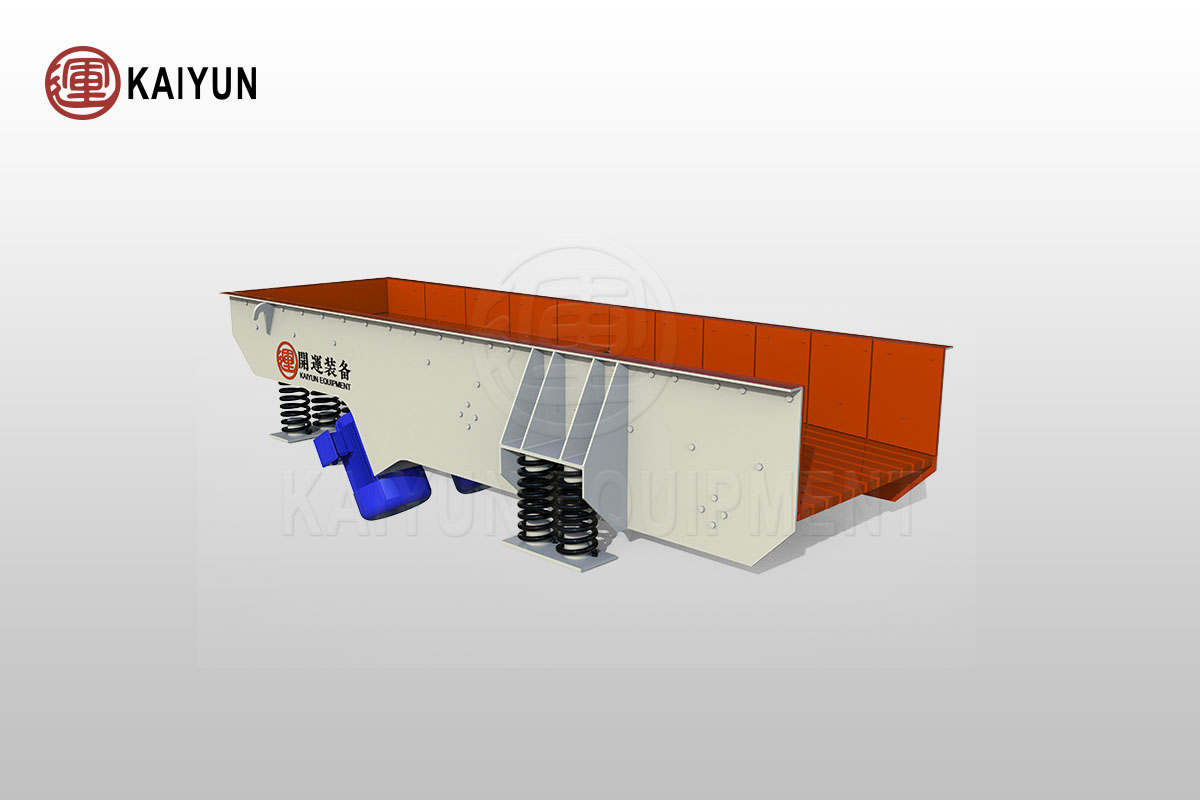

Product Overview

GZT Vibrating Feeder, specifically designed for light-duty conditions, stands out as an ideal feeding solution for mobile stations, semi-fixed stations, and small material yards. With its distinctive design and exceptional performance, this feeder is particularly suited for providing stable and continuous material supply to jaw crushers, primary impact crushers, and hammer crushers.

Additionally, GZT Vibrating Feeder serves as an efficient material transport assistant, demonstrating extensive application potential in the mineral processing industry.

Table of Contents

Performance Features

Weld-Free Side Panels, Stable Structure

The innovative weld-free side panel design fundamentally eliminates the risk of cracking, ensuring stable operation and long service life even in challenging conditions.

Vibration Motor Drive, Low Failure Rate

Utilizing a vibration motor as the vibration source reduces the likelihood of failures and simplifies maintenance, providing users with a hassle-free experience.

Compact Structure, Ideal for Mobile Stations

The compact and lightweight design makes it an ideal partner for mobile stations, effortlessly adapting to various site changes for efficient and flexible material feeding.

Bar Design with Pre-Screening Function

The built-in bar structure features a pre-screening function, effectively removing unqualified materials and enhancing the efficiency and capacity of subsequent crushing equipment.

Rubber Spring Support, Smooth Operation

Rubber springs provide support, significantly reducing vibration and noise during operation, creating a more comfortable working environment and extending the overall lifespan of the equipment.

Technical Parameters

| Model | Max.Feed Size (mm) | Capacity (t/h) | Power (kw) | Rod Angle (°) | Double Amplitude (mm) | Dimension (L*W*H)(mm) |

| GZT-0932 | 560 | 80-150 | 2*2.2 | 10 | 4-8 | 3298*1512*1141 |

| GZT-0940 | 560 | 80-180 | 2*3.7 | 10 | 4-8 | 4100*1818*1134 |

| GZT-1148 | 600 | 150-300 | 2*5.5 | 10 | 4-8 | 4926*1676*1479 |

| GZT-1256 | 800 | 180-400 | 2*12 | 10 | 4-8 | 5704*1840*1707 |

| GZT-1560 | 1000 | 400-600 | 2*13 | 10 | 4-8 | 6126*2208*1588 |