Product Introduction

The high weir spiral classifier, designed specifically for coarse particle classification, utilizes the differences in settling velocities of solid particles in the slurry to achieve efficient and precise classification.

The high weir spiral classifier innovative automated return sand lifting system not only enhances the stability of the ball mill operation but also significantly reduces energy consumption, making it a key component in modern mineral processing workflows.

Table of Contents

Advantages

Automated Return Sand Lifting

The high weir spiral classifier features an automated return sand lifting system that replaces traditional large scoop head configurations. This ensures smoother operation of the ball mill, reducing equipment vibration and noise, and improving the comfort of the working environment.

Significant Energy Savings

Compared to similar equipment, the high weir spiral classifier saves 1 to 1.5 kwh of energy per ton of ore processed, demonstrating exceptional energy efficiency. This contributes to lowering production costs and supports the development of green mining practices.

Balanced Impact Protection

The classifier effectively mitigates uneven impacts on the ball mill’s large and small gears, extending equipment life and reducing maintenance frequency, thereby enhancing overall production efficiency.

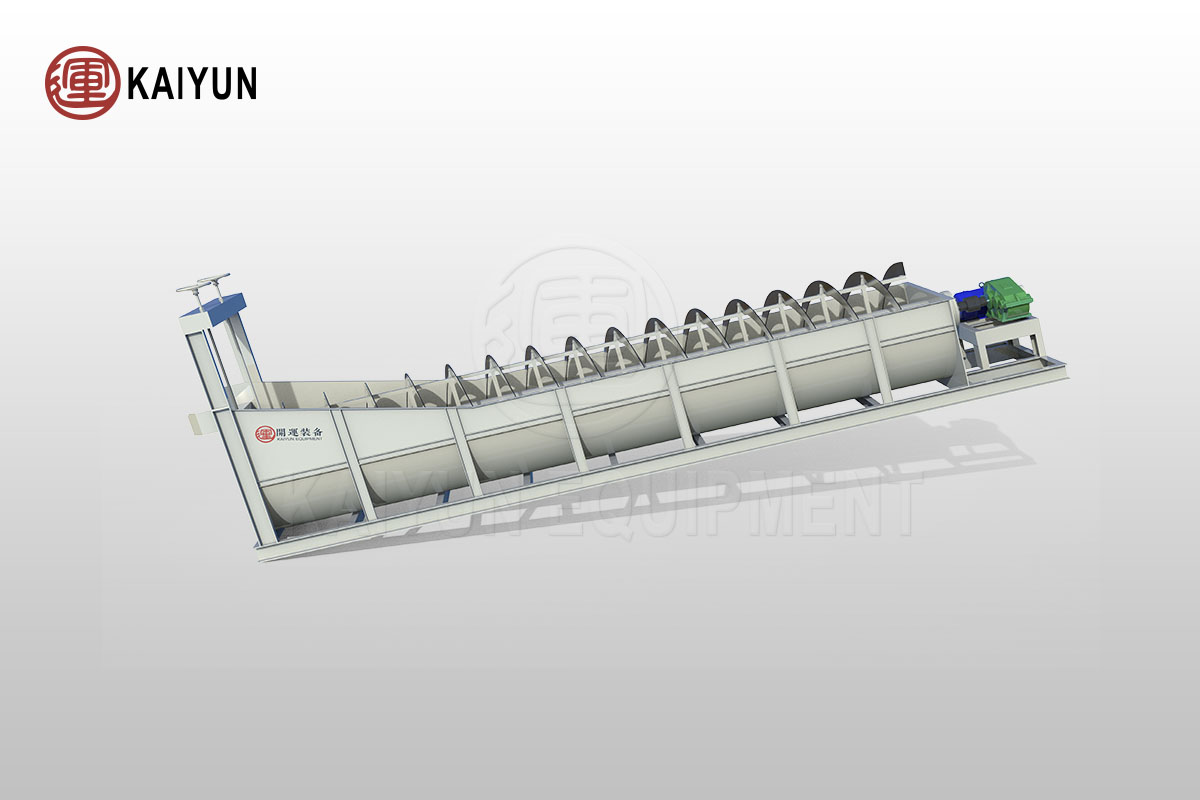

Working Principle

The working principle of the high weir spiral classifier is based on the settling characteristics of the slurry. The finely ground slurry is fed uniformly into an inclined tank through an inlet located in the center of the settling zone. Below the tank is a spacious slurry classification and settling area where the spiral shaft rotates slowly, acting as a stirrer. This rotation keeps fine particles suspended above the slurry and allows them to flow to the overflow weir, where they exit the classifier.

Coarse particles, on the other hand, settle to the bottom of the tank and are conveyed by the spiral shaft to the discharge port as return sand, re-entering the grinding process.

Notably, the overflow weir of the high weir spiral classifier is designed to be higher than the bearing center at the lower end of the spiral shaft but lower than the upper edge of the overflow-end spiral. This unique design increases the area of the settling zone and allows for adjustable weir height within a certain range. This means users can flexibly adjust the classification particle size according to actual needs, providing significant convenience and flexibility for the grinding circuit.

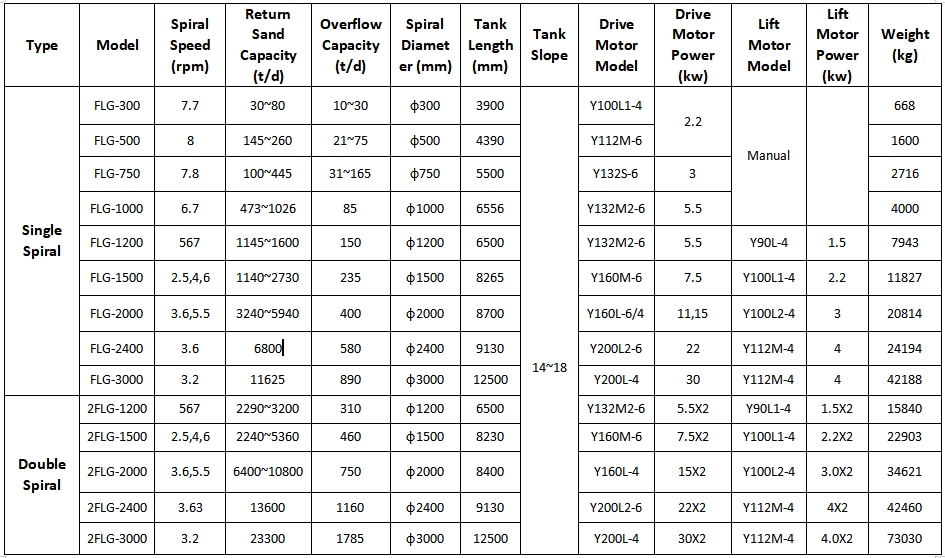

Technical Parameters