Product Introduction

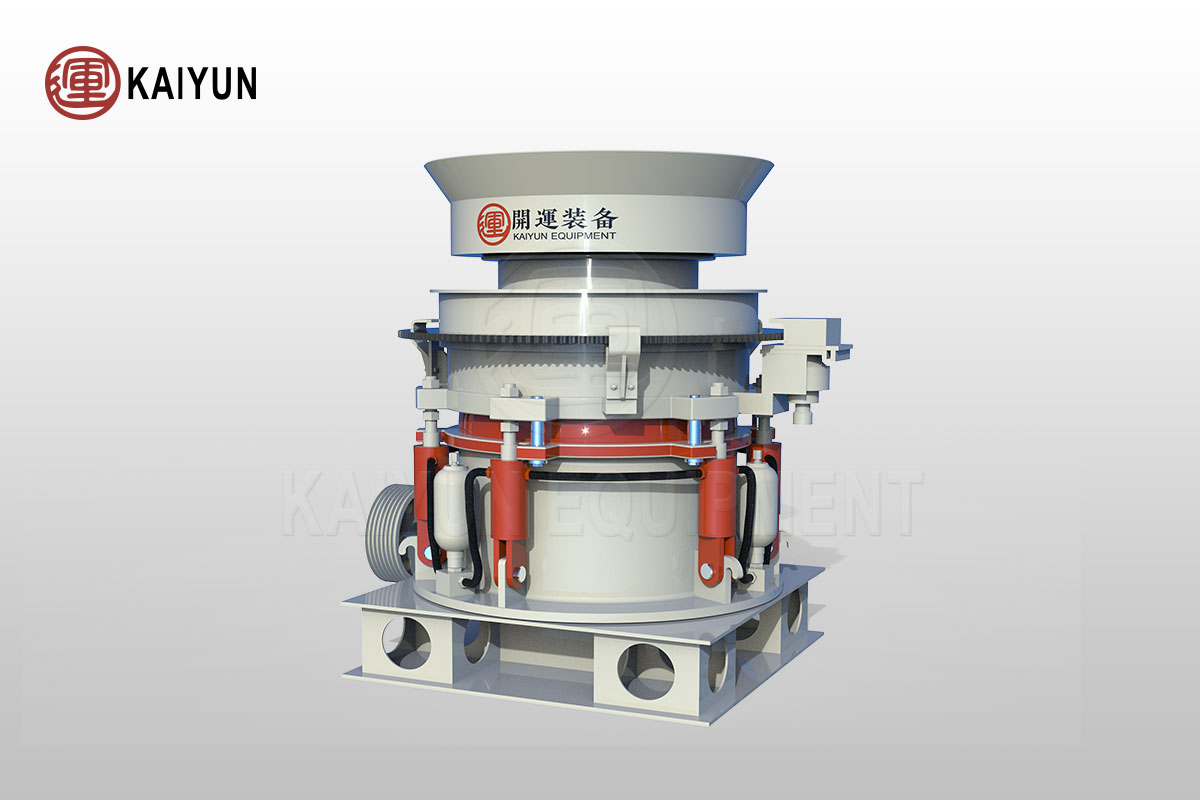

HPT series multi-cylinder hydraulic cone crusher embodies the essence of international cutting-edge technology. After careful research and improvement, it has become a high-performance masterpiece today and has become the preferred tool for fine crushing operations in the mining and sand and gravel industries.

HPT series multi-cylinder hydraulic cone crusher is designed for heavy-duty operations and has excellent stability. Its unique integrated main frame design, combined with large eccentricity, high speed and intelligent control system, greatly improves production capacity and crushing efficiency.

Applicable Materials and Industry Scenarios

Applicable Materials:

Medium-to-high-hardness ores such as granite, basalt, iron ore, river pebbles, slag, limestone, diabase, and bauxite

Applicable Industries:

Metal mine crushing

Building materials sand production

Secondary/tertiary crushing in stone processing plants

Aggregate crushing for railway/highway/hydropower projects

📌 Recommended Supporting Equipment: Vibrating screen, jaw crusher, sand making machine, belt conveyor

Table of Contents

Performance Features

⚙️Efficient crushing chamber design

HPT series multi-cylinder hydraulic cone crusher,Various crushing chamber options available, providing fine particle size and strong fine crushing performance.

🔧Hydraulic automatic adjustment & overload protection

Automatically adjusts the discharge opening to prevent iron blockage and protect the equipment.

🧩Modular structure & easy maintenance

HPT series multi-cylinder hydraulic cone crusher,Compact structure and standardized components ensure efficient maintenance.

🧱Effortless handling of hard materials

Easily crushes hard materials such as granite, basalt, and iron ore.

🔄Automatic chamber clearing function

HPT series multi-cylinder hydraulic cone crusher,One-touch hydraulic chamber clearing reduces downtime.

🧰Can be configured as a complete crushing system

Combined with a vibrating screen, jaw crusher, and conveyor to form a two- or three-stage crushing line.

Working Principle

When HPT series multi-cylinder hydraulic cone crusher working, the motor drives the eccentric sleeve to rotate through the V-belt, transmission shaft, and transmission gear. Under the action of the eccentric sleeve, the moving cone performs a swinging motion. This motion causes the moving cone and the fixed cone to periodically approach and depart from each other, continuously compressing and impacting the material to break it. The crushed material is discharged from the bottom discharge opening.

The adjustment of the discharge opening size is achieved by driving the hydraulic cylinder piston, which can be done by controlling the oil intake and return volume of the hydraulic cylinder, making the operation simple, precise, and reliable.

Technical Parameters

| Model | Capacity (TPH) | Discharge Opening Range (mm) | Max Feed Size (mm) | Motor Power (kw) | Weight (t) |

| HPT200 | 65-260 | 6-38 | 170 | 160 | 12.5 |

| HPT300 | 90-450 | 8-45 | 240 | 250 | 18.6 |

| HPT400 | 110-645 | 8-51 | 300 | 315 | 26.0 |

| HPT500 | 135-800 | 8-55 | 310 | 400 | 37.6 |

| HPT600 | 225-800 | 10-55 | 330 | 500 | 45.5 |

| HPT800 | 265-1220 | 10-60 | 350 | 630 | 66.4 |

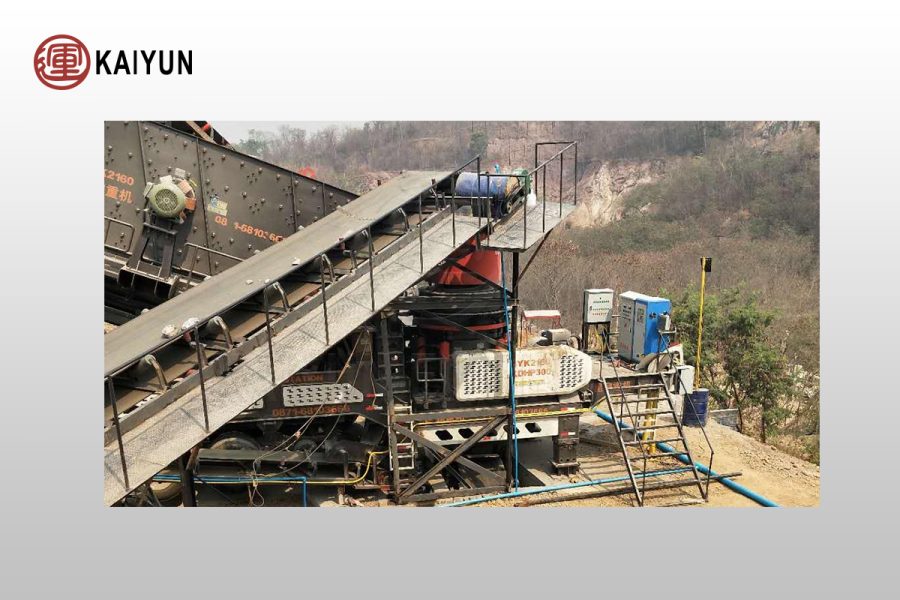

Customer Case

Sand and Gravel Aggregate Crushing Project in Thailand

Model: PE750 Jaw Crusher + HPT300 Cone Crusher + Screening System

Ore: Granite

Output Size: 10-20 mm

Processing Capacity: 250 tons/hour

Customer Feedback: Smooth operation, easy maintenance, and uniform particle size. Recommended to partners.