Product Introduction

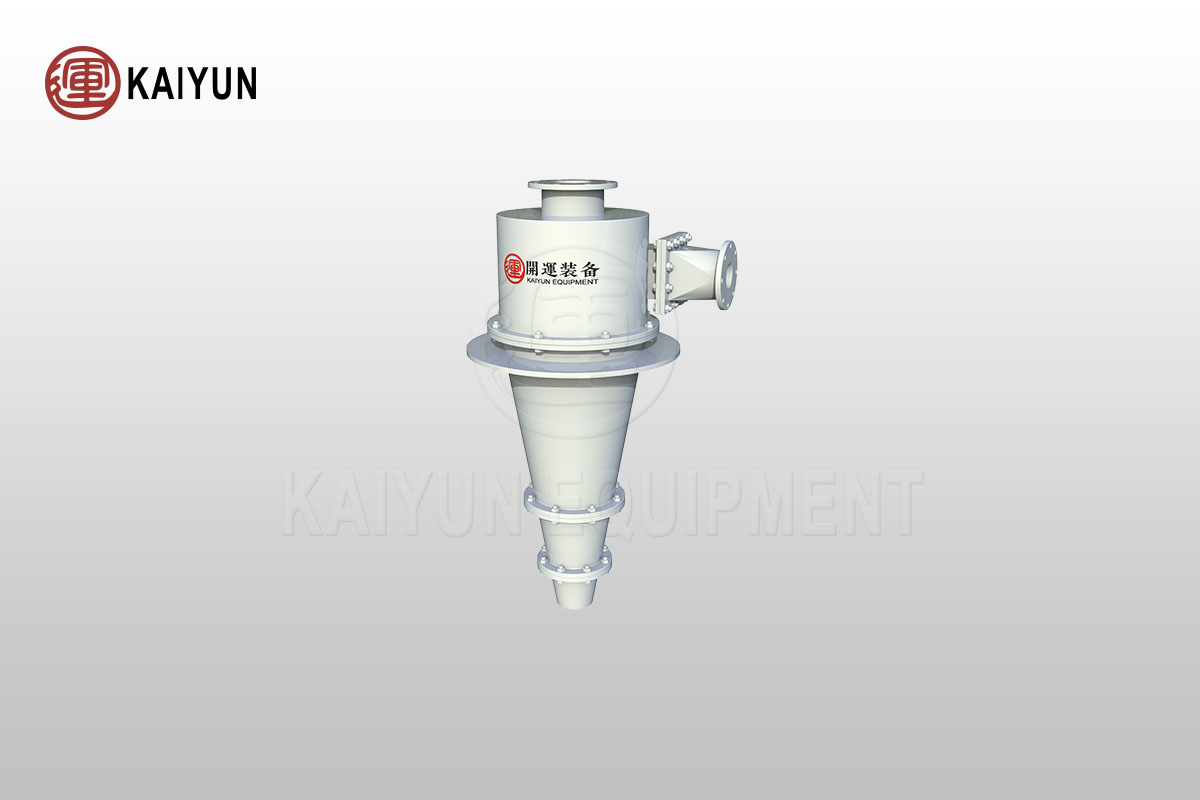

The hydrocyclone, an efficient fluid separation device with an involute feed design, significantly enhances the centrifugal force applied to materials, optimizing classification results while effectively reducing wear on the feed box.

The hydrocyclone unique involute feed inlet design makes it an ideal choice for operations in mineral processing, chemical, petroleum, environmental protection, and other industries, including classification, concentration, dehydration, desliming, sand removal, washing, and fine classification.

Table of Contents

Advantages

Involute Feed Design

The involute feed inlet not only enhances the centrifugal force applied to the material, improving separation efficiency, but also significantly reduces wear on the feed box, extending the equipment’s service life.

Smooth Operation and Reduced Wear

The involute feed method effectively prevents turbulence caused by sudden dispersion when the material enters the hydrocyclone, ensuring smooth operation within the device, improving separation performance, and reducing impact wear on the feed box.

Optimized Structural Ratio

The design of the column-cone section length ratio and the depth of the overflow pipe insertion maximizes classification efficiency, ensuring higher separation precision and stability.

Wear-Resistant Rubber Lining

Using wear-resistant rubber as the lining material significantly enhances the durability of the hydrocyclone, extending its service life by 2-4 times, and reducing maintenance costs and downtime.

High Classification Standards and Stability

With a well-designed structure, the hydrocyclone achieves high classification indicators with minimal fluctuation, ensuring consistent separation results and meeting the stringent requirements for separation accuracy in industrial production.

Working Principle

The hydrocyclone operates based on the principle of centrifugal sedimentation. When a mixture of two or more phases is fed into the hydrocyclone under pressure, it generates intense three-dimensional elliptical rotational shear turbulence. Due to differences in particle density, the centrifugal force, centripetal buoyancy, and fluid drag experienced by particles vary.

Under the influence of centrifugal sedimentation, most of the coarse particles (or heavier phase) are directed to the underflow outlet of the hydrocyclone, while most of the fine particles (or lighter phase) exit through the overflow pipe. This results in efficient and precise separation and classification. This process is effective not only for solid-liquid separation but also for liquid-liquid separation, demonstrating the hydrocyclone’s strong adaptability and flexibility across various applications.

Technical Parameters

| Model | Specifica | Handling Capacity (m³/h) | Classification Particle Size (µm) | Overflow Outlet Diameter (mm) | Underflow Outlet Diameter (mm) | Inlet Pressure (MPa) |

| XCF 150 | 150 | 10 ~23 | 25 ~74 | 30 ~50 | 8~22 | 0.06 ~0.15 |

| XCF 200 | 200 | 17 ~38 | 28 ~80 | 40 ~65 | 16 ~32 | 0.06 ~0.15 |

| XCF 250 | 250 | 24 ~53 | 30 ~82 | 65~100 | 16 ~40 | 0.06 ~0.15 |

| XCF 300 | 300 | 40~100 | 36 ~90 | 65~120 | 20 ~40 | 0.06 ~0.15 |

| XCF 350 | 350 | 56~118 | 40~100 | 80~120 | 30 ~70 | 0.06 ~0.15 |

| XCF 375 | 375 | 74~157 | 42~105 | 90~135 | 30 ~70 | 0.06 ~0.15 |

| XCF 450 | 450 | 90~192 | 44~110 | 100~150 | 30 ~70 | 0.06 ~0.15 |

| XCF 500 | 500 | 128~300 | 50~115 | 130~220 | 35~100 | 0.06 ~0.15 |

| XCF 550 | 550 | 155~368 | 52~120 | 140~240 | 35~100 | 0.06 ~0.15 |

| XCF 600 | 600 | 200~468 | 57~125 | 160~260 | 65~110 | 0.06 ~0.15 |

| XCF 660 | 660 | 237~524 | 60~130 | 180~280 | 80~150 | 0.06 ~0.15 |