Product Introduction

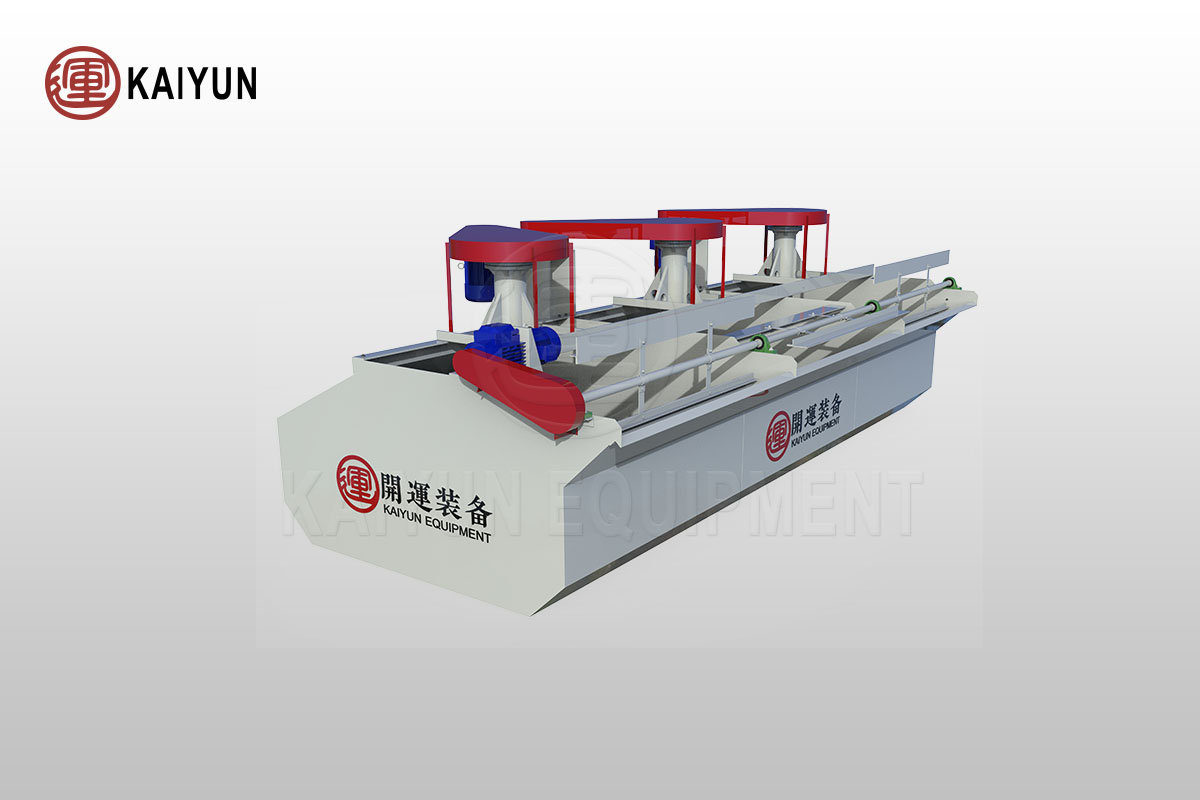

The JJF Mechanical Agitation Flotation Machine, designed as a self-aspirating flotation device without slurry suction, offers exceptional solutions for the separation of non-ferrous metals, ferrous metals, and non-metallic minerals. Its innovative tank design, optimized rotor and stator configuration, and efficient bubble dispersion technology make it particularly suitable for roughing and scavenging operations in large and medium-sized flotation plants. The JJF machine demonstrates remarkable stability and reliability under complex working conditions.

Table of Contents

Advantages and Features

Shallow Tank Design and Low Energy Consumption

The shallow tank design and smaller rotor diameter with low rotation speed of the flotation machine not only reduce energy consumption but also ensure cost-effectiveness. The larger gap between the rotor and stator, along with the special elliptical holes in the stator, promotes efficient mixing and dispersion of air and slurry, enhancing flotation efficiency.

Optimized Slurry Circulation and Dispersion

The design of a stator height lower than the rotor significantly increases slurry circulation, with a circulation ratio up to 2.5 times. This enhances the full contact between ore, reagents, and air, improving mineralization. The umbrella-shaped dispersion cover effectively isolates the vortex generated by the rotor from the froth layer, maintaining slurry surface stability and improving process controllability.

Wide Processing Capacity

The JJF flotation machine is capable of handling a wide range of particle sizes with high ore recovery rates. It can accommodate various mineral separation needs, efficiently processing both coarse and fine materials.

Flexible Operation Configuration

Although it does not have slurry suction capabilities, the JJF flotation machine can be combined with SF flotation machines in a stepped arrangement (drop height of 300-400 mm) to form a unified flotation system for efficient operation. The SF flotation machine serves as the suction cell, while the JJF flotation machine functions as the direct-flow cell, together creating an efficient flotation process.

Working Principle

In the JJF mechanical agitation flotation machine, vortexes generated within the vertical cylinder and guide tubes create a negative pressure. Air is drawn in through the air inlet pipe and is mixed thoroughly with the slurry introduced via the guide tubes in the rotor and stator region. Driven by the rotor, this slurry-air mixture moves tangentially, and then, under the action of the stator, is converted into radial motion, distributing uniformly throughout the flotation tank. The mineralized bubbles rise to the froth layer, where they are collected through either single-side or double-side scraping, thereby achieving effective separation and enrichment of the ore.

Technical Parameters

| Model | Effective Volume (m³) | Processing Capacity (m³/min) | Impeller diameter (mm) | Impeller speed (r.p.m) | Stirring motor power (kw) | Scraper motor power (kw) | Single Tank Weight (kg) |

| JJF-4 | 4 | 2.0-4 | 410 | 305 | 11 | 1.5 | 2303 |

| JJF-5 | 5 | 2.0-6 | 410 | 305 | 11 | 1.5 | 2416 |

| JJF-8 | 8 | 4.0-12 | 540 | 233 | 22 | 2.2 | 4507 |

| JJF-10 | 10 | 5.0-10 | 540 | 233 | 22 | 1.5 | 4820 |

| JJF-16 | 16 | 5.0-16 | 700 | 180 | 37 | 1.5 | 7657 |

| JJF-20 | 20 | 5.0-20 | 770 | 180 | 45 | 1.5 | 8505 |