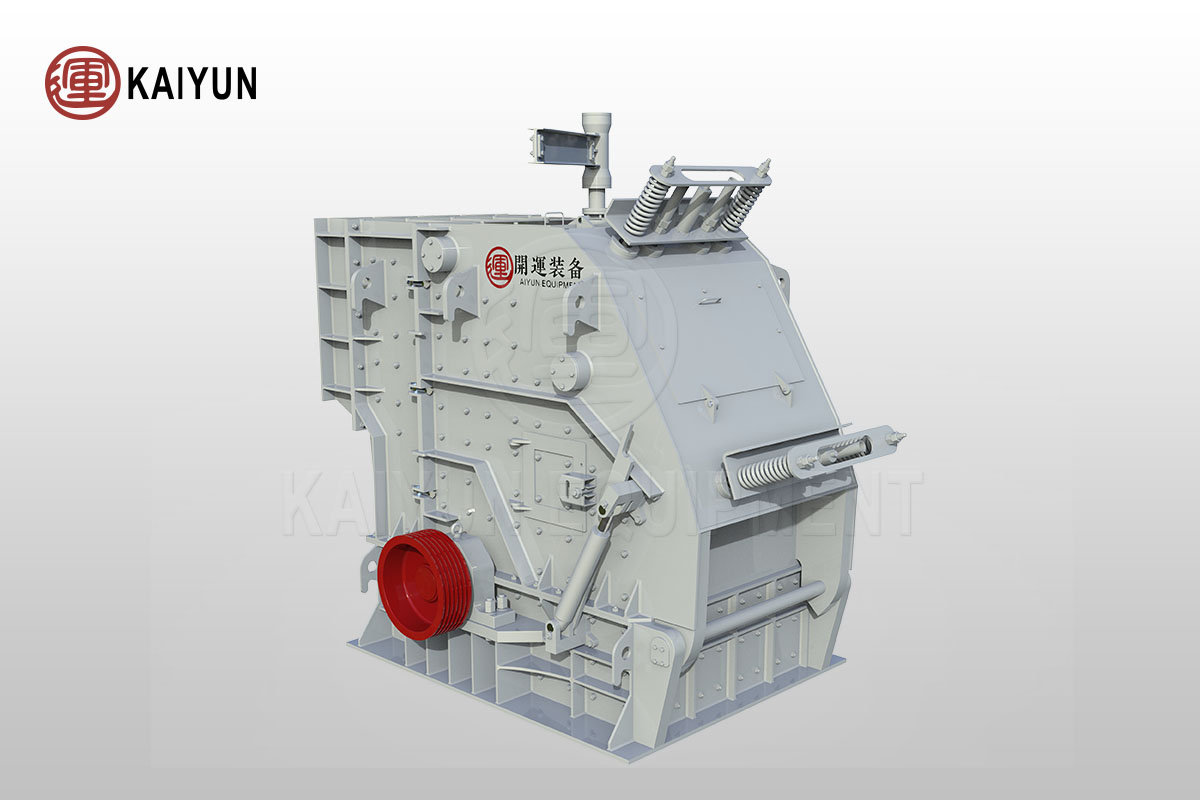

Product Introduction

KNP series impact crusher is an efficient equipment in the field of ore processing, particularly suitable for coarse and medium-fine crushing operations. Its outstanding crushing performance, versatile application range, and stable operational characteristics make it the preferred crushing equipment in various industries.

Application

KNP series impact crushers application industries

Construction Aggregate Production Lines

Secondary Crushing in Mines

Concrete Recycling and Processing

Crushing of Urban Construction Waste

Intermediate Crushing in Sand Making Systems

KNP series impact crushers typical materials

Medium-hard materials such as limestone, concrete, construction waste, coal gangue, bricks, shale, and quartz stone.

Table of Contents

Performance Features

⚙️ High crushing ratio

One-step crushing achieves a crushing ratio of up to 1:10~1:20, suitable for a wide range of coarse, medium and fine crushing applications.

📐 Fine particle shape, minimal needle-like flakes

Cubic output, suitable for sand making and concrete aggregate production.

🔧 Hydraulic cover opening & easy maintenance

KNP series impact crusher, easy replacement of blow bars/impact plates reduces downtime.

🧱 Versatile material adaptability

KNP series impact crusher can crush medium-hard materials such as limestone, concrete, coal gangue, and construction waste.

🔩 Optional rotor and liner configurations

Optimize crushing performance based on material characteristics.

🚧 Can be integrated into a mobile crushing station

KNP series impact crusher suitable for flexible on-site deployment, a core component of a mobile crushing system.

Parameter

| Model | Feed port size (mm) | Maximum feed particle diameter (mm) | Weight (t) | Power (kw) |

| KNP1007 | 750×800 | 500 | 7.2 | 90 |

| KNP1110 | 1020×820 | 600 | 9.3 | 160 |

| KNP1213 | 1320×880 | 600 | 12.8 | 200 |

| KNP1315 | 1540×930 | 600 | 16.1 | 250 |

| KNP1520 | 2040×995 | 700 | 27.1 | 400 |

| KNP1210 | 1020×1060 | 800 | 12.8 | 160 |

| KNP1313 | 1320×1200 | 900 | 17.8 | 200 |

| KNP1415 | 1540×1320 | 1000 | 21.8 | 250 |

| KNP1620 | 2040×1630 | 1300 | 40.5 | 400 |

| KNP2023 | 2400×1920 | 1500 | 74.2 | 1000 |