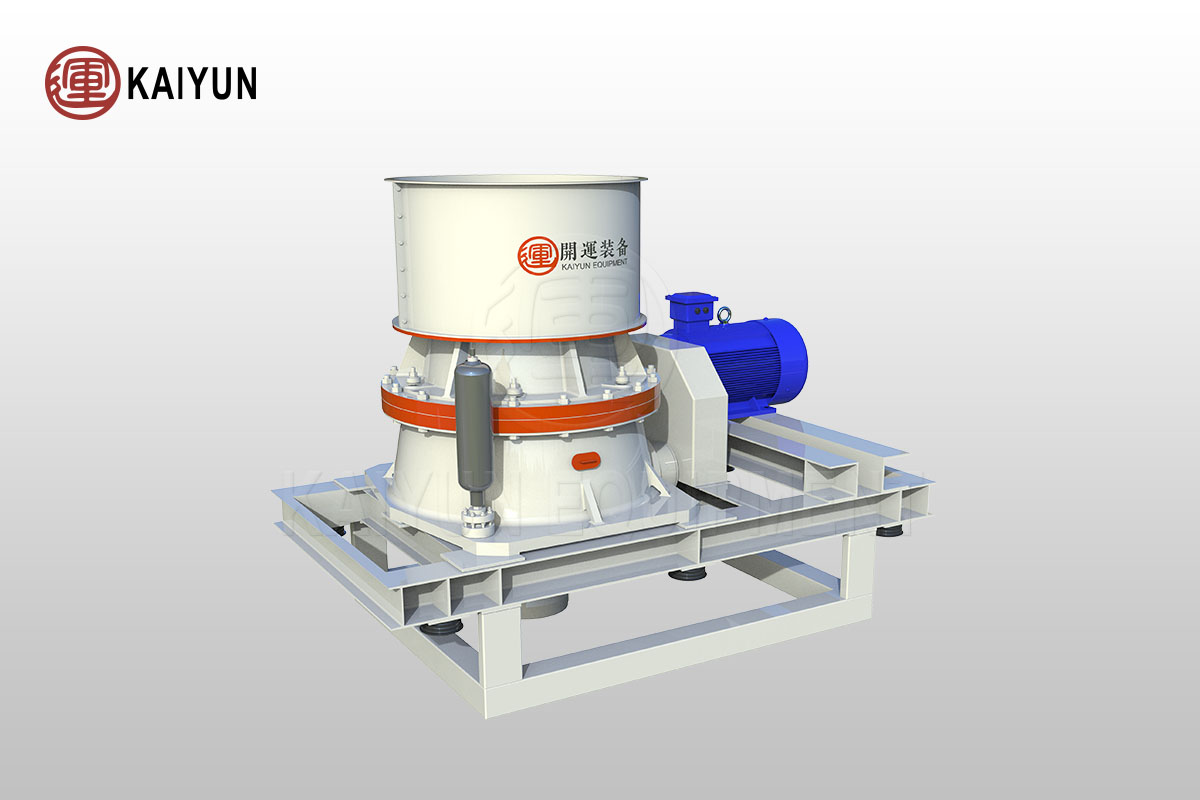

Product Introduction

KS/H series single-cylinder hydraulic cone crusher, a cornerstone in the modern mining and stone industries, is divided into the KS and KH series. These crushers seamlessly integrate advanced technologies in mechanics, hydraulics, electronics, and intelligent control, and are specifically designed for heavy-duty conditions.

KS/H series single-cylinder hydraulic cone crushers are widely applicable to production lines of various scales, exhibiting exceptional performance and adaptability in both coarse and medium-fine crushing operations. As large-scale equipment, these models boast higher production capacities and a broader range of discharge opening adjustments, making them suitable for large mining and stone processing enterprises.

Table of Contents

Product Features

⚙️ High efficiency and fine particle shape

Adopting an optimized crushing chamber + fixed axis design, the crusher produces cubic particles and uniform discharge.

🔧 Hydraulic + Automated Adjustment

The hydraulic cylinder integrates discharge adjustment, chamber clearing, and overload protection.

🛠️ Simple structure and low failure rate

KS/H series single-cylinder hydraulic cone crusher,Compared to multi-cylinder crushers, the crusher boasts a more compact structure, fewer components, and easier maintenance.

💡 Intelligent Control

Supports PLC control system for remote operation and data monitoring.

🧱 High adaptability

KS/H series single-cylinder hydraulic cone crusher,Suitable for crushing hard materials such as granite, iron ore, basalt, and pebbles.

📦 Flexible configuration as a mobile crusher

KS/H series single-cylinder hydraulic cone crusher,Can be paired with a crawler or tire-mounted mobile crushing station to adapt to changing construction sites.

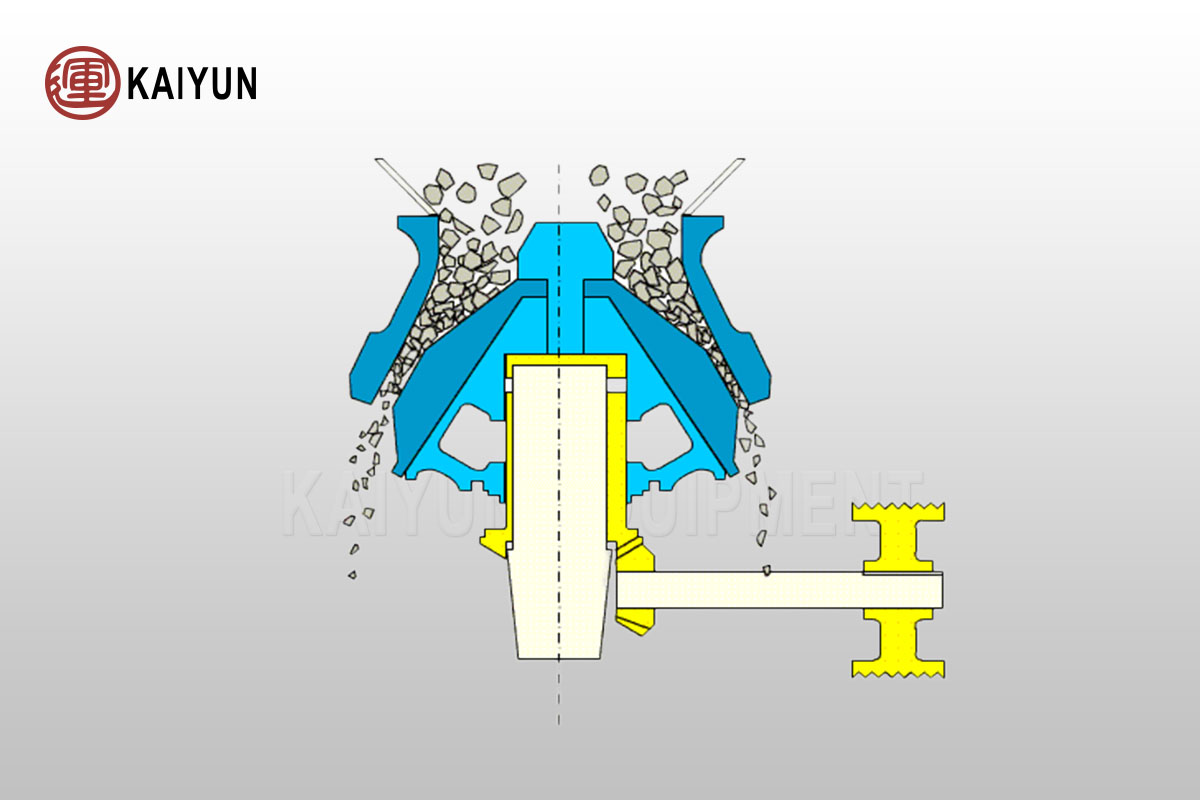

Working Principle

The working principle of the KS/H series single-cylinder hydraulic cone crusher is both ingenious and efficient. The motor drives the pinion, which in turn drives the large gear assembly and the eccentric sleeve assembly to revolve around the central axis. Simultaneously, the main shaft assembly rotates within the eccentric copper sleeve, creating a unique crushing action.

When material enters the crushing chamber, it is crushed by the compressive force of the inner cone. The equipment features an intelligent hydraulic protection system that automatically adjusts the discharge opening when encountering uncrushable objects, effectively preventing blockages and protecting the machine from damage.

Application Scenarios + Applicable Materials Module

Applicable Scenarios

Secondary/tertiary crushing in mines (copper, iron, gold, etc.); Fine crushing in manufactured sand plants; High-grade sand and gravel aggregate processing lines; Core crushing equipment in mobile crushing plants

Applicable Materials

Granite, basalt, iron ore, river pebbles, gold ore, construction waste, diabase, limestone, and other medium-to-high-hardness rocks

Technical Parameters

| Model | Capacity (TPH) | Discharge Opening Range (mm) | Max Feed Size (mm) | Motor Power (kw) | Weight (t) |

| KS420 | 70-166 | 19-38 | 240 | 90 | 6.8 |

| KS430 | 90-330 | 19-51 | 360 | 160 | 12 |

| KS440 | 190-610 | 25-54 | 350 | 250 | 19.3 |

| KS660 | 310-1020 | 33-83 | 560 | 315 | 35.7 |

| KH420 | 25-120 | 4-35 | 135 | 90 | 5.3 |

| KH430 | 36-210 | 5-38 | 185 | 160 | 9.2 |

| KH440 | 66-412 | 6-44 | 215 | 250 | 143 |

| KH660 | 140-650 | 10-51 | 275 | 315 | 26.8 |

| KH870 | 280-1550 | 10-70 | 300 | 600 | 50 |

| KH890 | 310-2090 | 13-70 | 370 | 750 | 76.1 |

| KH895 | 210-1070 | 13-70 | 100 | 750 | 79.1 |