Product Introduction

The Kaiyun Equipment LXB fiberglass spiral chute, combining high efficiency with high recovery rates, is a gravity separation device that utilizes the inertial centrifugal force generated by the slurry’s spiral rotation.

It achieves precise separation of fine-grained minerals ranging from 0.3 to 0.02 mm, including iron, tin, tungsten, tantalum, niobium, gold ore, coal, monazite, rutile, zircon, and other metals and non-metals with significant density differences.

Its outstanding performance and cost-effectiveness make it an ideal choice for modern mineral processing.

Table of Contents

Advantages and Features

Efficient Separation and High Recovery Rate

The LXB spiral chute, with its unique design, enables rapid and accurate separation of light and heavy minerals, significantly enhancing separation efficiency and recovery rates, ensuring the optimal utilization of mineral resources.

Cost-Effective and Quick Returns

Compared to other gravity separation equipment, the LXB spiral chute is affordable, easy to install, and intuitive to operate. Its low investment cost and quick returns make it a preferred choice for mineral processing enterprises seeking economic benefits.

Lightweight, Durable, and Corrosion-Resistant

Made from fiberglass, the LXB spiral chute is lightweight and offers excellent rust resistance, abrasion resistance, and corrosion resistance, extending the equipment’s lifespan and reducing maintenance costs.

Space and Water Conservation

With a compact structure, minimal footprint, and low water consumption, the LXB spiral chute eliminates the need for additional power devices, simplifying the operation process and reducing energy consumption.

Strong Adaptability and Flexibility

It has strong adaptability to fluctuations in feed amount, concentration, particle size, and grade, allowing for flexible adjustments based on different ore characteristics, ensuring stable separation results.

Working Principle and Design Highlights

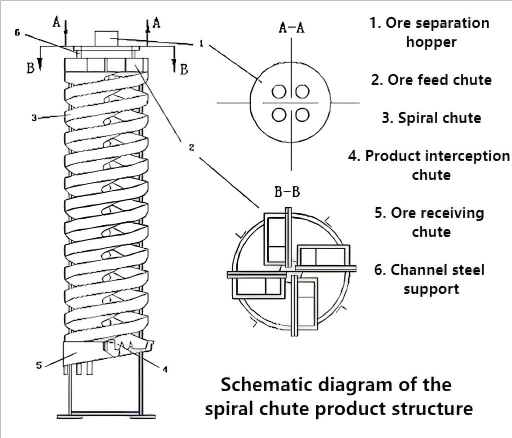

Uniform slurry is slowly fed in through the feeding trough installed at the head end of the spiral chute, and the slurry is sorted on the spiral trough surface. At the tail end of the spiral chute, the valve block type product interception trough divides the sorted products into three types according to grade along the radial direction.

By adjusting the position of the valve block, the interception width of each product can be flexibly adjusted to achieve accurate collection of products of different grades. The product collection bucket collects and exports the intercepted multi-head ore flows separately, ensuring the orderly output of the sorted products.

The cross-section and curve slope design of the spiral chute are particularly suitable for the sorting of fine and particulate materials, ensuring high precision and stability during the sorting process, and further improving the sorting effect.

Technical Parameters

| Model | 2000 | 1500 | 1200 | 900 | 600 | 400 |

| Spiral outer diameter (mm) | 2000 | 1500 | 1200 | 900 | 600 | 400 |

| Pitch (mm) | 1200 | 900, 675 | 900,720 540 | 675, 540, 405 | 450,360,270 | 240,180 |

| Pitch-to-diameter ratio (pitch/diameter) | 0.6 | 0.48, 0.36 | 0.75, 0.6, 0.459 | 0.75, 0.6, 0.45 | 0.75, 0.6. 0.45 | 0.6, 0.45 |

| Lateral inclination (°) | 9° | 9° | 9° | 9° | 9° | 9° |

| Number of installed spiral heads | 2 | 2-4 | 2-4 | 2-4 | 2 | 2 |

| Feed particle size (mm) | 2.00~0.04 | 2.00~0.04 | 2.00~0.04 | 2.00~0.04 | 2.00~0.04 | 2.00~0.04 |

| Feed concentration (%) | 30~55 | 30 ~55 | 25 ~55 | 25 ~55 | 25 ~55 | 25 ~55 |

| Production capacity (t/h) | 7~10 | 3~5 | 3~4 | 2~3 | 0.8~1.2 | 0.15~0.2 |

| Length (mm) | 2120 | 1600 | 1360 | 1060 | 700 | 460 |

| Width (mm) | 2120 | 1600 | 1360 | 1060 | 700 | 460 |

| Height (mm) | 5600 | 5300 | 5230 | 4600 | 2600 | 1500 |

| Weight (kg) | 1200 | 800 | 600 | 400 | 150 | 50 |