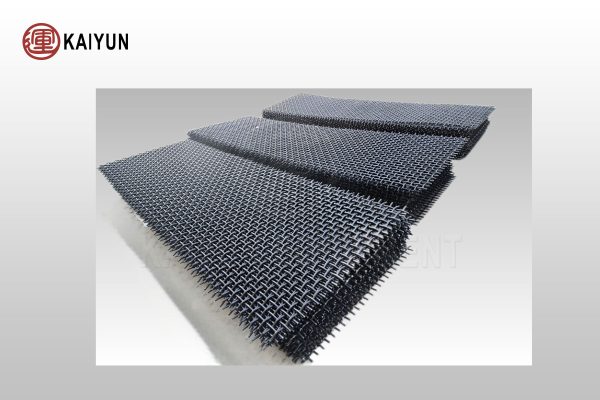

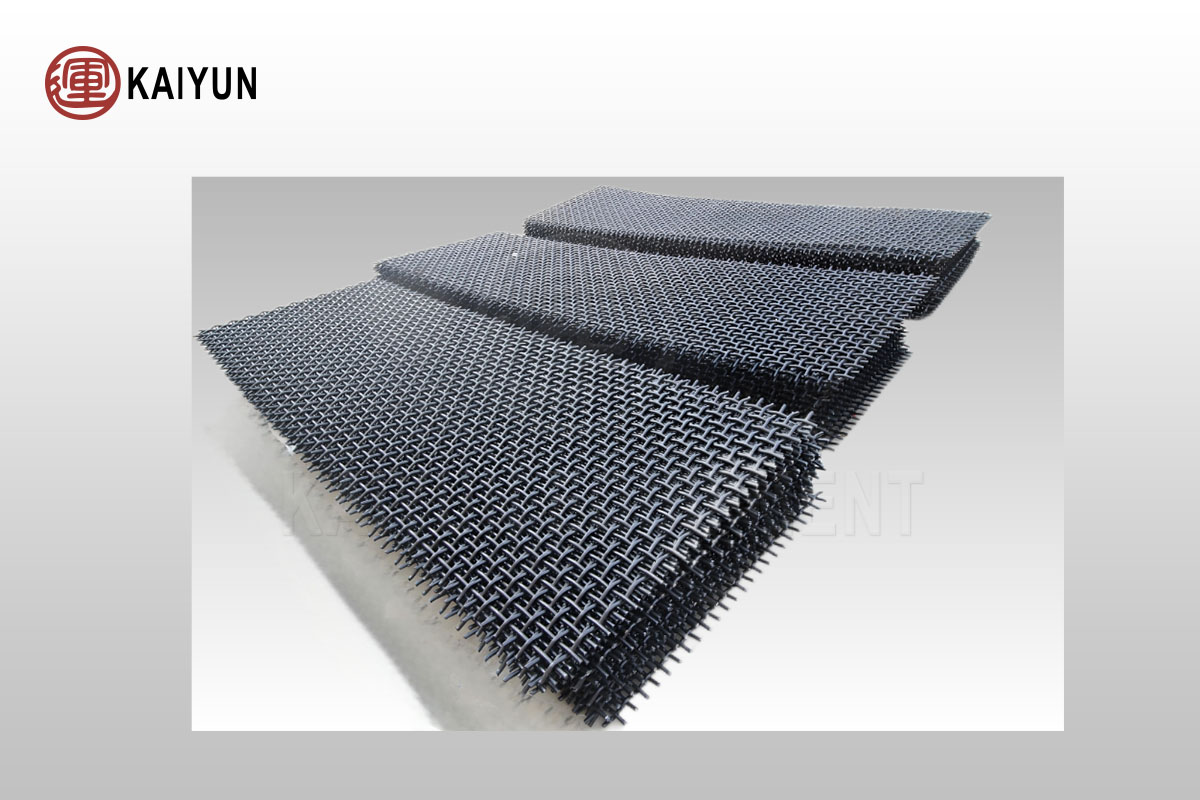

Product Overview

Manganese Steel Screen Mesh is an indispensable metal mesh component used in screening, filtration, dewatering, and mud removal processes. Its distinct feature is the embedded weaving method, which ensures that the intersections of the warp and weft are flat and flush. This results in a smooth surface and uniform stress distribution across the screen mesh, effectively preventing material jamming issues caused by protruding mesh openings during the screening process.

Table of Contents

Core Advantages and Features

High Strength and Rigidity

Manganese steel screen mesh is renowned for its exceptional mechanical properties, providing high strength and rigidity. It can withstand intense material impacts and wear, making it suitable for harsh conditions and ensuring stability and durability.

Outstanding Load-Bearing Capacity

The high load-bearing capacity of manganese steel allows the screen mesh to handle large volumes of material. Whether dealing with heavy loads or high-speed vibrations, it maintains excellent performance and extends the mesh’s service life.

Customizable Shapes and Sizes

Manganese steel screen mesh can be customized to various shapes and sizes to meet specific industrial needs. Whether for linear vibrating screens, circular vibrating screens, or other types of screening equipment, suitable manganese steel mesh options are available.

Wide Applicability

As a commonly used mesh in vibrating screens, manganese steel mesh is versatile across various industries, including mining, metallurgy, coal, chemical, and construction. It is an ideal choice for screening, filtration, dewatering, and mud removal processes.