Product Introduction

MC Series Crawler Mobile Cone Crusher, the main machine adopts multi-cylinder circularity, laminated crushing, and is equipped with a large torque slow-speed feeder to ensure uniform feeding. It is mainly used for secondary crushing and is suitable for medium and high hardness rocks. The whole machine is compact, easy to transfer, with large crushing output, low corrosion and high reliability.

Core advantages: hard rock nemesis, ultra-high energy efficiency, intelligent pre-screening.

Table of Contents

Applicable fields

Secondary and tertiary crushing stages of medium and high hardness materials.

Crushing and sand making of highly wear-resistant stones (Si0, content higher than 75%) such as river pebbles, granite, and diabase in quarries.

Pre-ball milling crushing of iron ore in large-scale ore dressing plants.

Structural advantages

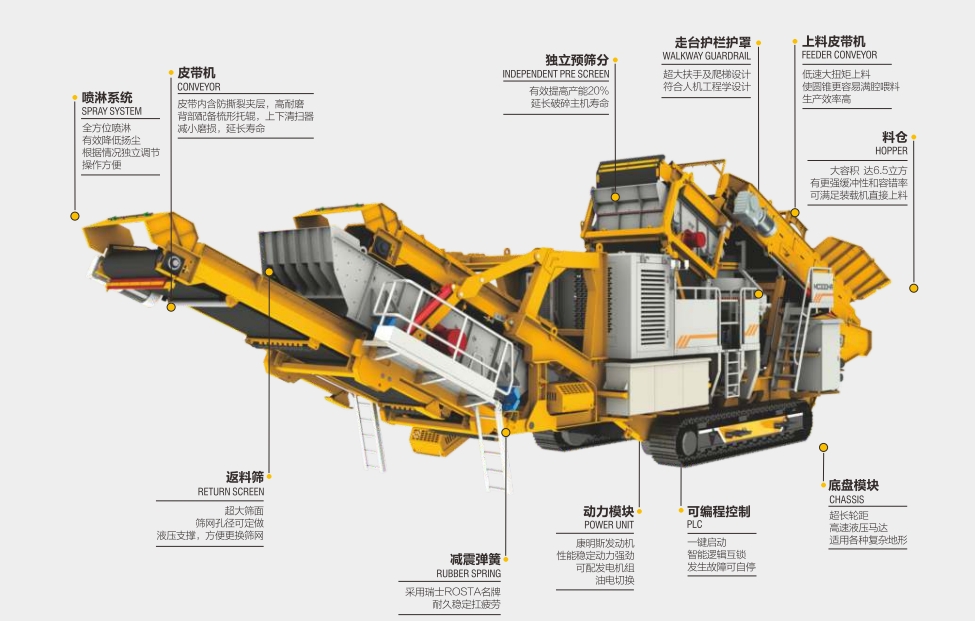

Spraying system

All-round spraying effectively reduces dust, and it is easy to operate by independent adjustment according to the situation.

Belt conveyor

The belt contains a tear-resistant interlayer, and the high wear-resistant back is equipped with a comb-shaped roller. The upper and lower sweepers reduce wear and extend life.

Return screen

Super large screen surface, the screen aperture can be customized. Hydraulic support, easy to replace the screen.

Independent pre-screening

Effectively increase production capacity by 20% and extend the life of the crushing host.

Power module

Cummins engine, stable performance, strong power, can be equipped with generator set, oil-electric switch.

Shock-absorbing spring

Adopts Swiss ROSTA brand, durable, stable and anti-fatigue.

Walkway guardrail cover

Extra-large handrail and ladder design, in line with ergonomic design.

PLC

One-button start, intelligent logic interlock, automatic stop in case of failure.

Feeding belt conveyor

Low-speed and high-torque feeding makes it easier to feed the cone with full cavity and high production efficiency.

Silo

Large volume of 6.5 cubic meters, with stronger buffering and fault tolerance, can meet the direct feeding of loaders.

Chassis module

Extra-long wheelbase, high-speed hydraulic motor, suitable for various complex terrains.

Parameter

| MC-300S | MC-300SR | MC-300H | MC-300HRE | MC-300HR | |

| Feeding equipment | |||||

| Volume(m³) | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 |

| Feeding height (mm) | 2870 | 2870 | 2870 | 2870 | 2870 |

| Maximum size (mm) | 225 | 225 | 225 | 225 | 225 |

| Feeding capacity(t/h) | 500 | 500 | 500 | 500 | 500 |

| Crusher | |||||

| Model | Single cylinder | Single cylinder | Multi-cylinder | Multi-cylinder | Multi-cylinder |

| Return screen(L*W)(mm) | / | 1540×3600 | / | 1540×3600 | 1540×3600 |

| Number of screen layers | / | / | / | 1 | 1 |

| Discharge range [mm} | 25-54 | 25-54 | 10-45 | 10-45 | 10-45 |

| Belt conveyor | |||||

| Main belt width (mm) | 1200 | 1200 | 1200 | 1200 | 1200 |

| Transfer belt width (mm) | 500 | 500 | 500 | 500 | 500 |

| Return belt width (mm) | 500 | 500 | 500 | 500 | 500 |

| Finished product belt width (mm) | 1200 | 1200 | 1200 | 1200 | 1200 |

| Finished product belt stacking height (mm) | 3419 | 3419 | 3419 | 3419 | 3419 |

| Complete machine | |||||

| Complete machine power(kw) | 308.7 | 338.7 | 308.7 | 338.7 | 338.7 |

| Main machine power(kw) | 250 | 250 | 250 | 250 | 250 |

| Processing capacity(t/h) | 290-495 | 290-495 | 150-430 | 150-430 | 150-430 |

| Travel speed(km/h) | 0.6-1 | 0.6-1 | 0.6-1 | 0.6-1 | 0.6-1 |

| Weight (t) | 52 | 57 | 55 | 64 | 60 |

| Transportation size(L*W*H) (mm) | 13850x3200x3800 | 18357x3300x3800 | 14850x3200x3800 | 19247x3070x3731 | 19247x3070x3731 |