Product Introduction

MJ Series Crawler Mobile Jaw Crusher is equipped with European C Series crushing machine, super large folding silo, independent pre-screening system, and iron removal spray device. It is mainly used for primary crushing of materials, with large feed size and wide discharge range, suitable for all kinds of rocks. Convenient transfer and high crushing efficiency.

Core advantages

Modular design enables quick installation and commissioning within 8 hours.

Save time and cost, no need for complex infrastructure construction.

Intelligent control system, easy to operate and dispatch.

Efficient crushing and screening capabilities, high output in a short period of time.

Flexibility and mobility, reducing transportation and downtime.

Applicable fields

Primary crushing or primary crushing of medium and high hardness materials

Mining ore crushing

Construction waste recycling

Construction aggregate production

Highway/railway

Road and bridge construction

Table of Contents

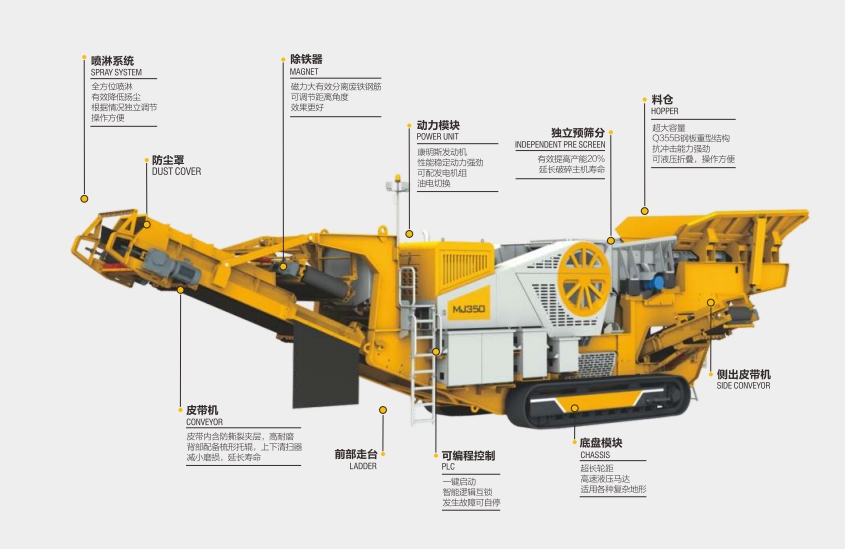

Structure Features

Spraying system

All-round spraying effectively reduces dust, and it is easy to operate by adjusting it independently according to the situation.

Iron remover

The strong magnetic force can effectively separate scrap iron and steel bars, and the adjustable distance and angle can achieve better results.

Power module

Cummins new engine, stable performance and strong power. It can be equipped with a generator set and switch between oil and electricity.

Independent pre-screening

Effectively increase production capacity by 20% and extend the life of the crushing host.

Silo

Ultra-large capacity, Q355B steel plate heavy-duty structure, strong impact resistance, hydraulic folding, easy operation.

Belt conveyor

The belt contains tear-proof interlayer and is highly wear-resistant. The back is equipped with comb-shaped rollers and upper and lower sweepers to reduce wear and extend life.

PLC

One-button start, intelligent logic interlocking, and automatic stop in case of failure.

Chassis module

Extra-long wheelbase and high-speed hydraulic motor make it suitable for various complex terrains.

Parameter

| MJ-150 | MJ-260 | MJ-350E | MJ-350 | MJ-350S | MJ-550 | |

| Feeding equipment | ||||||

| Volume(m³) | 4 | 6 | 6 | 6 | 6 | 9 |

| Feeding height (mm) | 4200 | 4350 | 4350 | 4350 | 4350 | 4500 |

| Maximum size (mm) | 460 | 560 | 630 | 630 | 630 | 700 |

| Feeding capacity(t/h) | 250 | 450 | 450 | 450 | 450 | 650 |

| Crusher | ||||||

| Model | C93 | C106 | C113 | C113 | C113 | C120 |

| Feeding size (mm) | 930×580 | 1060×700 | 1130×750 | 1130×750 | 1130×750 | 1200×870 |

| Discharge range [mm} | 40-175 | 70-200 | 70-200 | 70-200 | 70-200 | 70-275 |

| Belt conveyor | ||||||

| Main belt conveyor width (mm) | 1000 | 1200 | 1200 | 1200 | 1200 | 1400 |

| Main belt conveyor stacking height (mm) | 3200 | 3307 | 3307 | 3307 | 3200 | 3200 |

| Side belt conveyor(W*H)(mm) | 650×2196 | 650×2196 | 650×2196 | 650×2196 | / | 650×2196 |

| Drive mode | External motor reducer | External motor reducer | External motor reducer | External motor reducer | External motor reducer | External motor reducer |

| Complete machine | ||||||

| Complete machine power(kw) | 106.3 | 149.8 | 149.8 | 149.8 | 138.4 | 197.8 |

| Main machine power(kw) | 75 | 110 | 110 | 110 | 110 | 160 |

| Processing capacity(t/h) | 80-335 | 150-500 | 160-570 | 160-570 | 160-570 | 175-600 |

| Travel speed(km/h) | 0.6-1 | 0.6-1 | 0.6-1 | 0.6-1 | 0.6-1 | 0.6-1 |

| Weight (t) | 40 | 48 | 55.5 | 52 | 44 | 60 |

| Transportation size(L*W*H) (mm) | 12450x3000x3500 | 16354x3384x3725 | 516354x3384x3725 | 16354x3384x3725 | 13636x3160x3634 | 17600x3100x3800 |