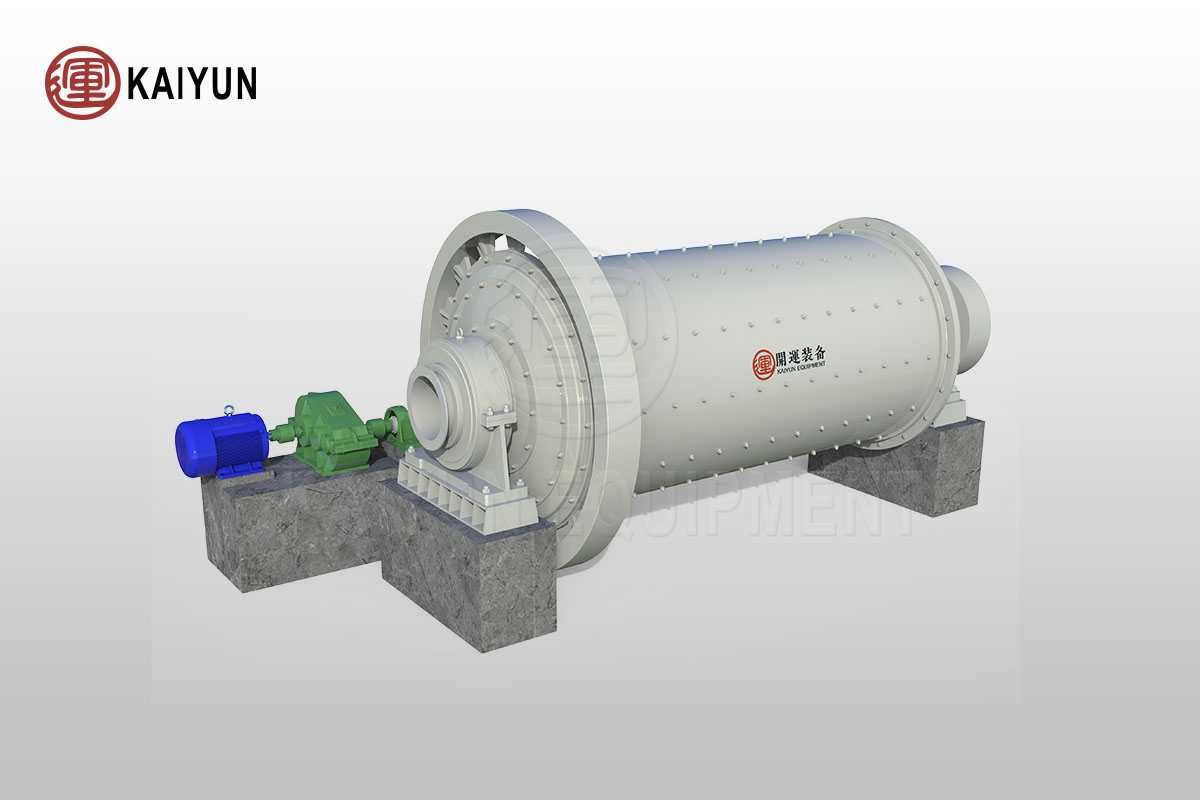

Product Introduction

The Kaiyun MQG wet grid type ball mill, as a classic and efficient grinding equipment, is specially designed for the processing of coarser ores. Its unique discharge grid structure ensures uniform discharge of materials, avoiding over-grinding, making it particularly suitable for the mining industry where coarse-grained products are required.

This model integrates several innovative technologies, including a convenient hydraulic jacking device, stable hydrostatic and hydrodynamic bearings, a slow transmission mechanism, an efficient oil mist lubrication system, and a variety of liner material options. Together, these features create an industrial tool that is easy to operate, low in maintenance costs, and reliable in performance.

Table of Contents

Performance Characteristics

Intelligent Hydraulic Jacking Device

Equipped with a hydraulic jacking function, it greatly simplifies the equipment maintenance process, making daily maintenance more efficient and faster.

Hydrostatic and Hydrodynamic Bearing System

Adopts advanced hydrostatic and hydrodynamic bearing technology to ensure the ball mill operates smoothly and reliably, reducing vibration and noise, and extending the equipment’s lifespan.

Slow Transmission Design

The slow transmission mechanism not only facilitates maintenance operations but also provides additional safety during startup, ensuring a smooth transition to normal operating conditions.

Oil Mist Lubrication Technology

The built-in oil mist lubrication device provides comprehensive lubrication protection for the large and small gears, effectively preventing wear and ensuring long-term stable operation of the transmission system.

Wear-Resistant Liner Material

The cylinder liner is available in a variety of wear-resistant materials, customized according to specific working conditions. This ensures excellent wear resistance, extends the equipment’s service life, and reduces operational costs.

Working Principle

The core of the Kaiyun MQG wet grid type ball mill lies in its slender rotating cylinder, driven by a precision transmission device. Material is continuously fed from one end of the cylinder, where the steel balls and ore interact. Through the dropping impact and self-grinding process, the material is crushed and refined. Under the pressure gradient within the cylinder, the material naturally migrates from the feeding end to the discharge end.

The finished material is then forcibly discharged through the grid plate at the discharge end. This design not only effectively controls the slurry surface height, preventing steel ball leakage, but also avoids over-grinding, ensuring the quality of the final product.

Technical Parameters

| Model | Diameter of cylinder (mm) | Length of cylinder (mm) | Motor model | Power (kw) | L*W*H (mm) | Effective volume (m3) | Ball loading (t) | Weight (kg) |

| MQG 0909 | 900 | 900 | Y225S-8 | 18.5 | 4750*2213*2050 | 0.45 | 0.96 | 4620 |

| MQG 0918 | 900 | 1800 | Y225M-8 | 22 | 5000*2280*2050 | 0.9 | 1.92 | 5340 |

| MQG 1212 | 1200 | 1200 | Y225M-8 | 22 | 5788*2994*2540 | 1.14 | 2.4 | 11438 |

| MQG 1224 | 1200 | 2400 | Y315S-8 | 55 | 6673*2994*2540 | 2.28 | 3.96 | 13200 |

| MQG 1515 | 1500 | 1500 | JR115-8 | 60 | 6094*3000*2766 | 2.5 | 5 | 13700 |

| MQG 1530 | 1500 | 3000 | JR125-8 | 95 | 7979*3300*2766 | 5 | 10 | 18690 |

| MQG 2122 | 2100 | 2200 | JR128-8 | 155 | 7750*4839*3794 | 6.6 | 15 | 45400 |

| MQG 2130 | 2100 | 3000 | JR137-8 | 210 | 8744*4395*3110 | 9 | 20 | 45790 |

| MQG 2430 | 2400 | 3000 | JR1410-8 | 280 | 9728*4956*4018 | 12.1 | 22.5 | 67000 |

| MQG 2721 | 2700 | 2100 | JR1410-8 | 280 | 9300*5500*4500 | 10.7 | 24 | 63000 |

| MQG 2727 | 2700 | 2700 | JR148-8 | 310 | 9900*5500*4500 | 13.8 | 29 | 68530 |

| MQG 2736 | 2700 | 3600 | TDMK400-32/2150 | 400 | 9765*5827*4675 | 18.4 | 41 | 98020 |

| MQG 3231 | 3200 | 3100 | TDMK630-36 | 630 | 12750*6750*5153 | 22.5 | 45 | 115103 |

| MQG 3236 | 3200 | 3600 | TDMK630-36 | 630 | 14300*6760*5200 | 24.8 | 58 | 119012 |

| MQG 3245 | 3200 | 4500 | TDMK800-36 | 800 | 13896*7200*5153 | 32.8 | 65 | 137589 |

| MQG 3639 | 3600 | 3900 | TDMK1000-36/3600 | 1000 | 15000*7200*6300 | 36.2 | 75 | 145000 |

| MQG 3645 | 3600 | 4500 | TDMK1250-40 | 1250 | 15200*7750*6300 | 41.8 | 90 | 159700 |

| MQG 3650 | 3600 | 5000 | TDMK1400-40 | 1400 | 17600*7750*6300 | 46.4 | 96 | 158000 |

| MQG 3660 | 3600 | 6000 | TDMK1600-40 | 1600 | 17000*8800*6500 | 55.7 | 120 | 189000 |

| MQG 4060 | 4000 | 6000 | TDMK1700-30 | 1700 | 17400*9500*7600 | 69.8 | 137 | 214000 |

| MQG 4560 | 4500 | 6000 | TDMK2300-30 | 2300 | 17800*10500*7600 | 87 | 158 | 294000 |