Product Description

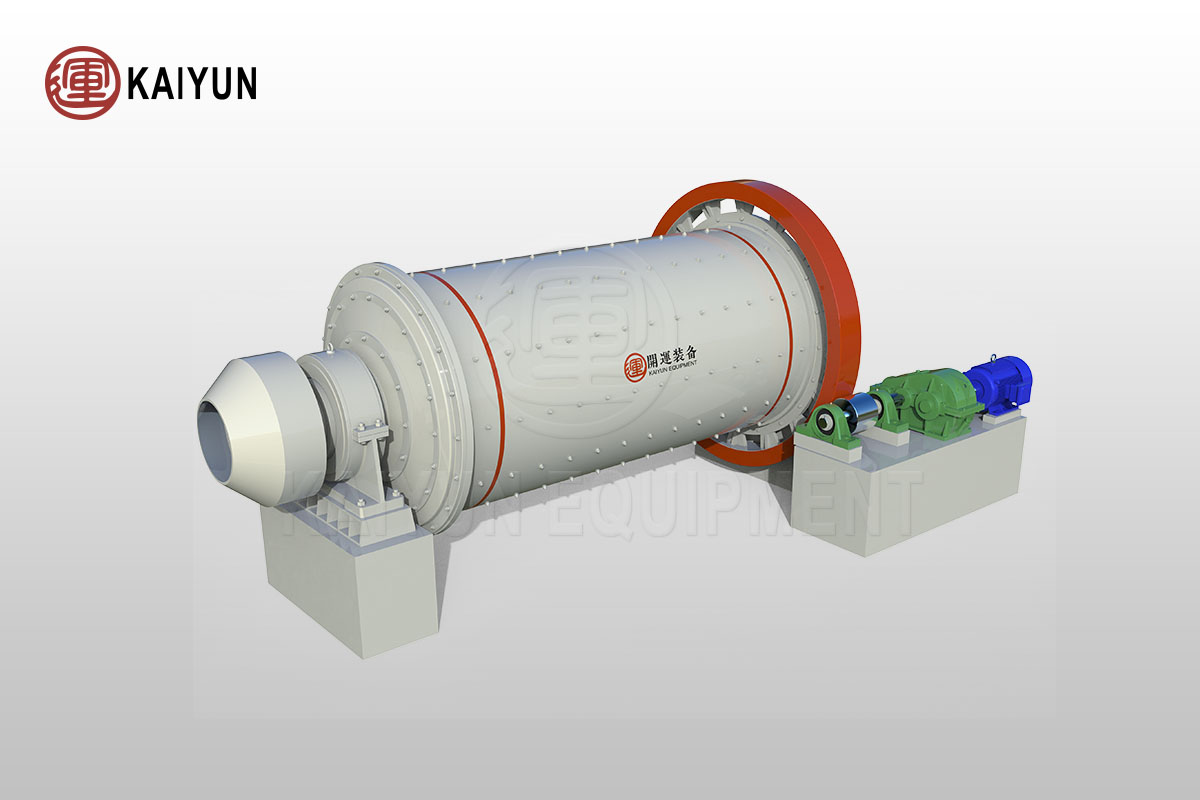

The Kaiyun MQGJ wet energy-saving grid type ball mill is an innovative equipment designed specifically to optimize ore grinding operations. It cleverly combines rolling bearing technology with efficient energy-saving features, aiming to provide outstanding wet grinding solutions for industries such as cement, silicate products, new building materials, refractory materials, fertilizers, black and non-ferrous metal ore beneficiation, as well as glass and ceramics.

Table of Contents

Working Principle

The core component of this ball mill is a slender rotating cylinder driven by a precision transmission system, rotating slowly. Material is fed into the cylinder from one end, where it undergoes fine grinding due to the impact and self-grinding effects between the steel balls and the ore inside.

The continuous input of material creates a pressure gradient, pushing the material from the feed end towards the discharge end of the cylinder, ensuring smooth discharge of the finished product. This flow mechanism also helps in controlling the residence time of the material inside the cylinder, thus preventing over-grinding.

Product Structure Advantages

Innovative discharge design

The discharge end of the ball mill is equipped with a discharge grid, which not only ensures that the slurry surface remains at a lower level and effectively prevents the leakage of steel balls, but also significantly enhances the discharge efficiency, ensuring timely discharge of materials and avoiding over-grinding issues.

Precision components

The MQGJ wet energy-saving grid type ball mill consists of key components such as the feeding part, discharging part, rotary part, and transmission part (including gearbox, small transmission gear, motor, and electrical control system), each meticulously designed to ensure outstanding overall performance.

Durable materials

The hollow shaft is made of high-quality cast steel, with a removable liner design for easy maintenance and replacement. The large rotary gear is manufactured using cast gear hobbing process, ensuring high precision and durability. The inner wall of the cylinder is lined with wear-resistant liners, significantly extending the equipment’s service life.

Energy-saving and efficient

By using rolling bearings instead of traditional sliding bearings, friction losses are greatly reduced, achieving significant energy savings. This also improves the operational stability and reliability of the equipment.

Technical Parameters

| Model | Diameter of cylinder(mm) | Length of cylinder (mm) | Motor model | Power (kw) | L*W*H (mm) | Capacity (t/h) | Effective volume (m3) | Maximum ball loading (t) | Weight(kg) |

| MQGJ 1212 | 1200 | 1200 | Y200L2-6 | 22 | 3512*2076*1620 | 0.17 ~4.1 | 1.14 | 2.4 | 9610 |

| MQGJ 1224 | 1200 | 2400 | Y280M-8 | 45 | 5745*2352*1773 | 0.26 ~6.15 | 2.4 | 4.6 | 12692 |

| MQGJ 1240 | 1200 | 4000 | JR117-8 | 80 | 7990*2210*2262 | 0.34~8.3 | 3.8 | 7.8 | 15932 |

| MQGJ 1515 | 1500 | 1500 | Y280M-8 | 45 | 5740*3075*2280 | 1.4~4.5 | 2.2 | 5 | 17125 |

| MQGJ 1530 | 1500 | 3000 | JR117-8 | 80 | 7253*3070*2280 | 2.8 ~9 | 5 | 10 | 21425 |

| MQGJ 1536 | 1500 | 3600 | JR126-8 | 110 | 8595*3185*2280 | 3~11 | 5.4 | 11.4 | 24213 |

| MQGJ 1545 | 1500 | 4500 | JR127-8 | 130 | 9680*3254*2370 | 3.5~12.5 | 7 | 12 | 27346 |

| MQGJ 1830 | 1800 | 3000 | JR136-8 | 180 | 8250*3620*2785 | 4.5 ~27 | 6.65 | 14 | 31850 |

| MQGJ 1836 | 1800 | 3600 | JR136-8 | 180 | 8866*3683*2785 | 4.5 ~29 | 8.2 | 13.8 | 35467 |

| MQGJ 1845 | 1800 | 4520 | JR137-8 | 210 | 9808*3683*2785 | 5~35 | 10.2 | 19 | 38909 |

| MQGJ 1856 | 1800 | 5620 | JR137-8 | 210 | 10909*3683*2785 | 6~40 | 12.2 | 22 | 41681 |

| MQGJ 1870 | 1800 | 7020 | JR138-8 | 245 | 12404*3783*2735 | 7~50 | 15 | 31.5 | 45166 |

| MQGJ 2122 | 2100 | 2200 | JR128-8 | 155 | 7135*4138*3083 | 5~29 | 6.6 | 20 | 38340 |

| MQGJ 2130 | 2100 | 3000 | JR136-8 | 180 | 8220*4220*3083 | 6.5 ~36 | 9 | 27 | 43100 |

| MQGJ 2136 | 2100 | 3600 | JR137-8 | 210 | 9155*4320*3433 | 7.5 ~42 | 10.8 | 23.5 | 45833 |

| MQGJ 2140 | 2100 | 4000 | JR137-8 | 210 | 9654*4320*3083 | 7.5 ~45 | 12.8 | 22.5 | 47265 |

| MQGJ 2145 | 2100 | 4500 | JR137-6 | 280 | 10350*4253*3125 | 10 ~50 | 13.5 | 23.6 | 52648 |

| MQGJ 2230 | 2200 | 3000 | JR137-8 | 210 | 8220*3864*3183 | 7.5 ~45 | 9.8 | 20.6 | 44600 |

| MQGJ 2430 | 2400 | 3000 | JR138-8 | 280 | 9024*4837*3490 | 7.2 ~92 | 11.5 | 22.5 | 59545 |

| MQGJ 2436 | 2400 | 3600 | JR138-8 | 320 | 9605*4837*3490 | 8 ~100 | 13.8 | 25.5 | 63933 |

| MQGJ 2442 | 2400 | 4200 | JR138-8 | 320 | 10205*4837*3490 | 8 ~110 | 16 | 30 | 67370 |

| MQGJ 2721 | 2700 | 2100 | JR138-8 | 245 | 8300*4787*3495 | 7.2 ~84 | 10.7 | 23 | 66743 |

| MQGJ 2727 | 2700 | 2700 | JR137-6 | 280 | 8901*4787*3490 | 7 ~110 | 13.8 | 29 | 71030 |

| MQGJ 2730 | 2700 | 3000 | JR1410-8 | 320 | 9610*5000*3495 | 8 ~115 | 15.3 | 32 | 83910 |

| MQGJ 2732 | 2700 | 3200 | JR1410-8 | 320 | 10724*5000*3620 | 8 ~120 | 15.7 | 32 | 88073 |

| MQGJ 2736 | 2700 | 3600 | JR158-8 | 380 | 10409*5150*3620 | 12~145 | 17.7 | 37 | 95300 |

| MQGJ 2740 | 2700 | 4000 | JR158-8 | 380 | 10609*5150*3620 | 12.5 ~152 | 19 | 42 | 98454 |

| MQGJ 2745 | 2700 | 4500 | JR1510-8 | 450 | 11534*5200*3670 | 13~160 | 22 | 40 | 100016 |

| MQGJ 2747 | 2700 | 4700 | JR1510-8 | 475 | 11779*5571*4175 | 13~170 | 23 | 45 | 101645 |

| MQGJ 2760 | 2700 | 6000 | JR1512-8 | 630 | 13299*5541*5140 | 15~200 | 30 | 60 | 119546 |

| MQGJ 2836 | 2800 | 3600 | JR1510-8 | 400 | 10964*5350*3670 | 13~160 | 19.7 | 41 | 106350 |

| MQGJ 3231 | 3200 | 3100 | TDMK630-36 | 630 | 12750*6750*5150 | 14~180 | 22.5 | 45 | 115430 |

| MQGJ 3245 | 3200 | 4500 | TDMK800-36 | 800 | 13896*7200*5153 | 95~110 | 32.8 | 65 | 147588 |

| MQGJ 3645 | 3600 | 4500 | TDMK1250-40 | 1250 | 18280*7700*5496 | 115~170 | 41.5 | 76 | 195727 |